Rare earth metal electrolysis intelligent feeding system and application method thereof

A rare earth metal and feeding system technology, applied in the direction of electrolysis components, electrolysis process, etc., can solve the problems of physical and mental harm of workers, uneven mixing of raw and auxiliary materials, poor stirring effect, etc., and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

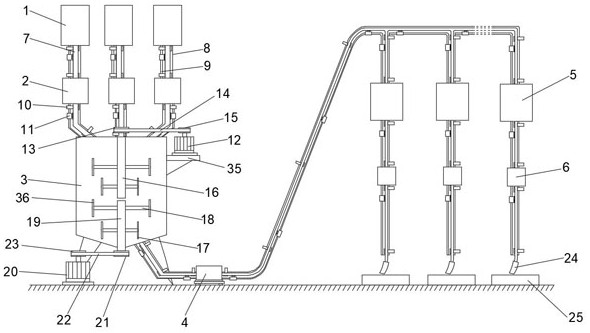

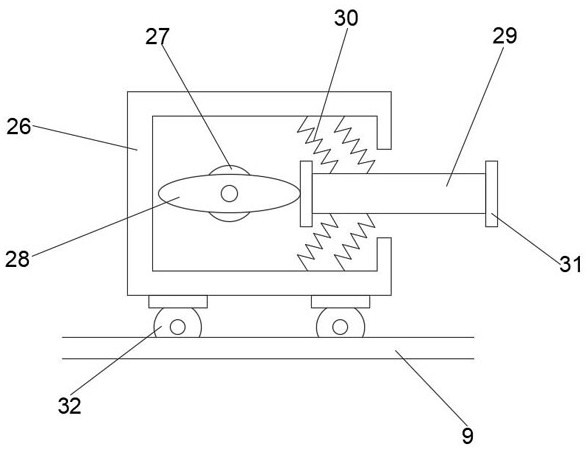

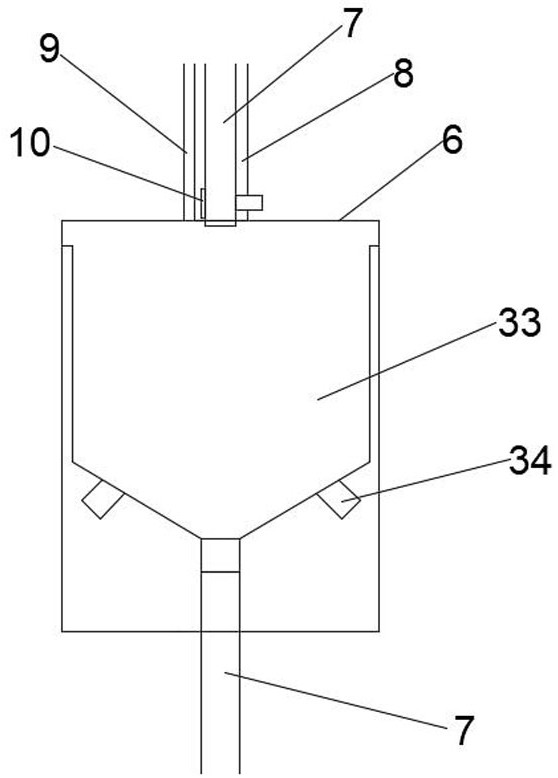

[0034] Such as Figure 1-3 As shown, an intelligent feeding system for rare earth metal electrolysis includes material tank 1, quantitative feeding tank I2, mixing tank 3, vacuum suction device 4, temporary storage tank 5 and quantitative feeding tank II6 arranged in sequence, and includes Blocking device and control system; a transparent material pipe 7 is connected between the material tank 1, the quantitative feeding tank I2, the mixing tank 3, the vacuum suction device 4, the temporary storage tank 5 and the quantitative feeding tank II6; The blocking device is arranged on each group of transparent material pipes 7; the deblocking device includes a support plate 8, a track 9, a photoelectric sensor 10 and a mobile vibration device 11; each group of the transparent material pipes 7 is provided with a group of supporting plate 8; the support plate 8 is arranged along the transparent material tube 7; the track 9 is arranged along the support plate 8; a group of photoelectric ...

Embodiment 2

[0045] The difference between this embodiment and Embodiment 1 is that: the end of the stirring rod 18 is provided with a stirring reinforcing rod 17 perpendicular to the stirring straight rod 18; the lengths of the adjacent two groups of the stirring rods 18 are different.

[0046] The usage method of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0048] The difference between this embodiment and Embodiment 2 is that: the upper side of the mixing tank 3 is provided with a support frame 35 ; the stirring motor I12 is provided on the support frame 35 .

[0049] The usage method of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com