Water chilling unit suitable for hydrogen refueling station and using method of water chilling unit

A chiller and hydrogenation machine technology, applied in the field of hydrogenation stations, can solve the problems that it takes a certain time to reach a usable state, consumes a large amount of electric energy, and the hydrogenation station is unacceptable, so as to shorten the hydrogenation time, save energy, and The effect of compact equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

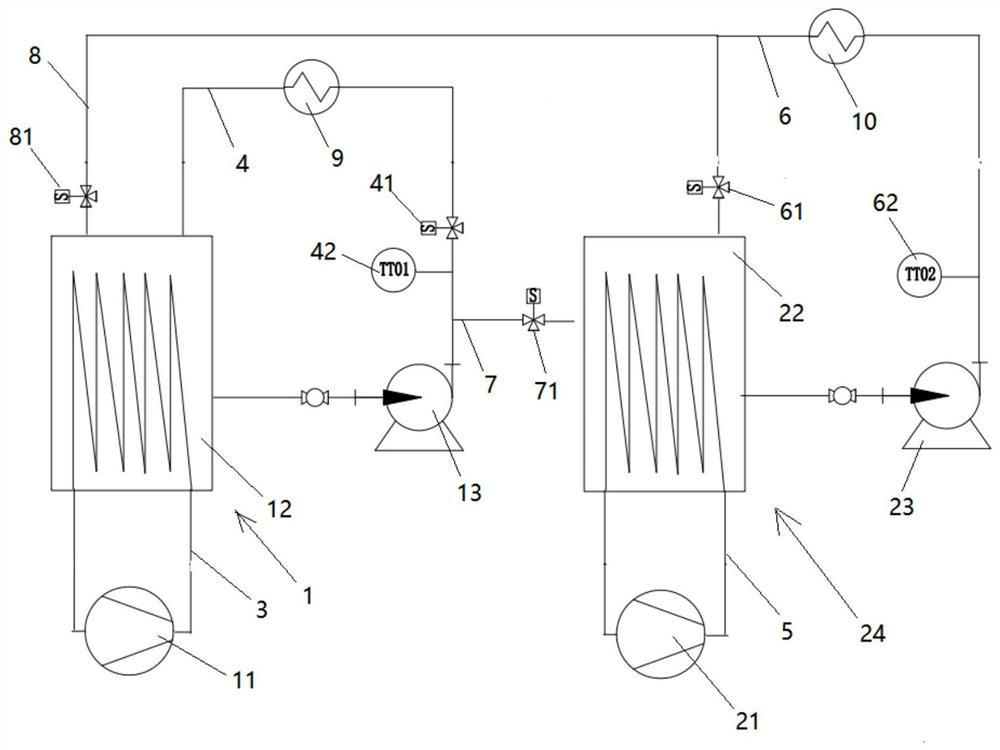

[0022] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0023] Such as figure 1 As shown, a chiller unit suitable for a hydrogenation station of the present invention includes a compressor chiller unit 1 and a hydrogenation machine chiller unit 2;

[0024] The compressor chiller unit 1 includes a first refrigeration compressor 11, a first evaporator 12, and a first water pump 13. The first refrigeration compressor 11 and the first evaporator 12 form a closed loop through the first pipeline 3. The first heat exchange The shell side of the device 9 and the first evaporator 12 form a closed circuit through the second pipeline 4, the tube side of the first heat exchanger 9 is connected with the hydrogen source after the pressurization of the compressor, and the first water pump 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com