Composite structure acoustic design method based on temperature variable frequency variable characteristic of damping material

A composite structure and damping material technology, applied in computer materials science, informatics, instruments, etc., can solve the problem that the frequency-varying characteristics of materials cannot be characterized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: Preparation of initial high-performance viscoelastic material

[0045] Based on butyl rubber (IIR), by adding hydrogenated dicyclopentadiene (HDCPD), polyisobutylene (PIB) and calcium carbonate (CaCO 3 ) by blending at least one of them, a modified butyl rubber (IIR compound) with high damping loss factor and wide effective damping temperature can be prepared. Among them, adding HDCPD can adjust the effective damping temperature range of modified butyl rubber; adding PIB can improve the loss factor of modified butyl rubber; adding calcium carbonate can improve the tensile strength of modified butyl rubber. The butyl rubber base is made of isoprene with a concentration of 1.6% and a density of 920kg / m 3 Pure IIR (BK1675N); HDCPD (PRS-5100) was purchased from Ruisen Petroleum Resin Co., Ltd.; PIB (long chain average molecular weight 2400) was purchased from Dalin Co., Ltd.; calcium carbonate was purchased from Tianwei Industrial Co., Ltd.

[0046] It was f...

Embodiment 2

[0054] Example 2: Characterization of material parameters for initial high-performance viscoelastic materials

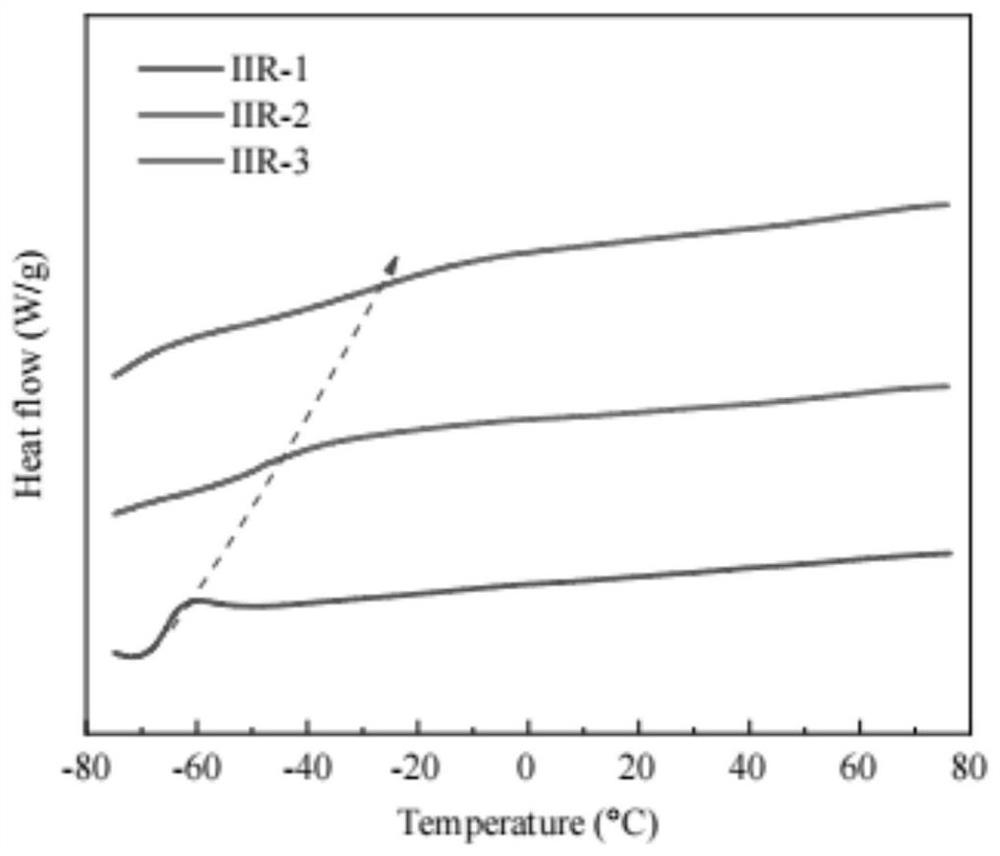

[0055] The glass transition temperature of the material was measured using a differential scanning calorimeter (DSC). The experiment was carried out under the condition of nitrogen protection. The nitrogen flow rate was 50ml / min. First, 8~10mg samples were cooled to -80°C at a cooling rate of 10°C / min, then kept at -80°C for 5min, and then cooled at 10°C / min. The heating rate of min heated the sample from -80°C to 80°C. The heat flow curves of IIR compounds with different contents of PIB and HDCPD as figure 1 shown.

[0056] From figure 1 It can be seen that the glass transition temperatures of IIR-1, IIR-2 and IIR-3 are -63.4°C, -44.2°C and -28.6°C, respectively. The results show that the glass transition temperature of the IIR compound becomes higher after PIB and HDCPD are blended with IIR. For different PIB content, the change of glass transition temperature...

Embodiment 3

[0062] Example 3: Heat transfer characteristics of aluminum profiles

[0063] The thermal environment will cause additional stiffness of the structure under thermal stress and affect its natural frequency and vibroacoustic characteristics. When a high-speed train is running outdoors, due to different geographical and weather factors, the temperature outside the train is generally -20°C to 40°C, while the temperature inside the train is constant at around 20°C. Therefore, there is usually a large temperature difference between the inside and outside of the aluminum profile (car body). In order to determine whether the thermal environment has a significant effect on the vibroacoustic properties of aluminum profiles, it is necessary to perform a heat transfer analysis.

[0064] There are three main mechanisms of heat transfer: (1) heat conduction; (2) heat convection; (3) heat radiation. Heat convection is the mode of heat transfer caused by relative motion between parts of dif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com