Cable with load operation monitoring function, particle for arc-shaped temperature-sensing color bar of cable, and co-extrusion method of arc-shaped temperature-sensing color bar

A technology of load operation and function, applied in the direction of power cable with shielding layer/conductive layer, insulated cable, cable/conductor manufacturing, etc., can solve the problems of cable short-circuit explosion, lower insulation, heat generation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

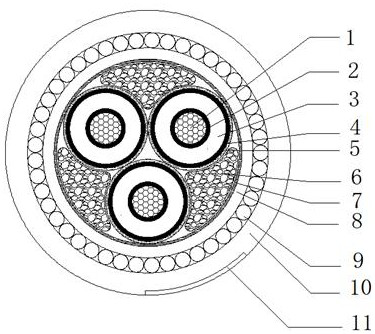

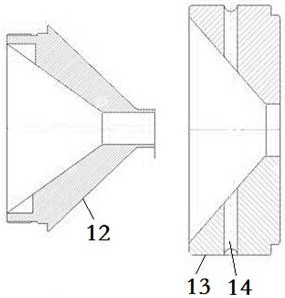

[0034] Such as figure 1 and figure 2 As shown, a cable with load operation monitoring function according to the present invention includes a conductor 1, a conductor shielding layer 2 is arranged outside the conductor 1, and an insulating layer 3 is arranged outside the conductor shielding layer 2, An insulating shielding layer 4 is arranged on the outside of the insulating layer 3, and a metal shielding layer 5 is arranged on the outside of the insulating shielding layer 4. They form a conductive unit, and the conductive unit is provided with three. A filling strip 6 is provided in the gap, and the filling strip 6 is a corrugated filling strip, and a non-hygroscopic tape cushion layer 7 is arranged outside the conductive unit and the filling strip 6, and a non-hygroscopic tape cushion layer 7 is arranged on the outside of the non-hygroscopic tape cushion layer 7. Extrusion is provided with a plastic isolation sheath layer 8, a steel wire armor layer 9 is provided outside th...

Embodiment 2

[0056] Such as figure 1 and figure 2 As shown, a cable with load operation monitoring function according to the present invention includes a conductor 1, a conductor shielding layer 2 is arranged outside the conductor 1, and an insulating layer 3 is arranged outside the conductor shielding layer 2, An insulating shielding layer 4 is arranged on the outside of the insulating layer 3, and a metal shielding layer 5 is arranged on the outside of the insulating shielding layer 4. They form a conductive unit, and the conductive unit is provided with three. A filling strip 6 is provided in the gap, and the filling strip 6 is a corrugated filling strip, and a non-hygroscopic tape cushion layer 7 is arranged outside the conductive unit and the filling strip 6, and a non-hygroscopic tape cushion layer 7 is arranged on the outside of the non-hygroscopic tape cushion layer 7. Extrusion is provided with a plastic isolation sheath layer 8, a steel wire armor layer 9 is provided outside th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com