A new type of waste incineration fly ash pyrolysis system and method

A technology for waste incineration fly ash and pyrolysis, which is applied in the fields of electric power and environmental protection, can solve the problems of high energy consumption, dioxin regeneration, and high equipment requirements, and achieves the goal of reducing energy consumption, reducing equipment investment, and eliminating the problem of regeneration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

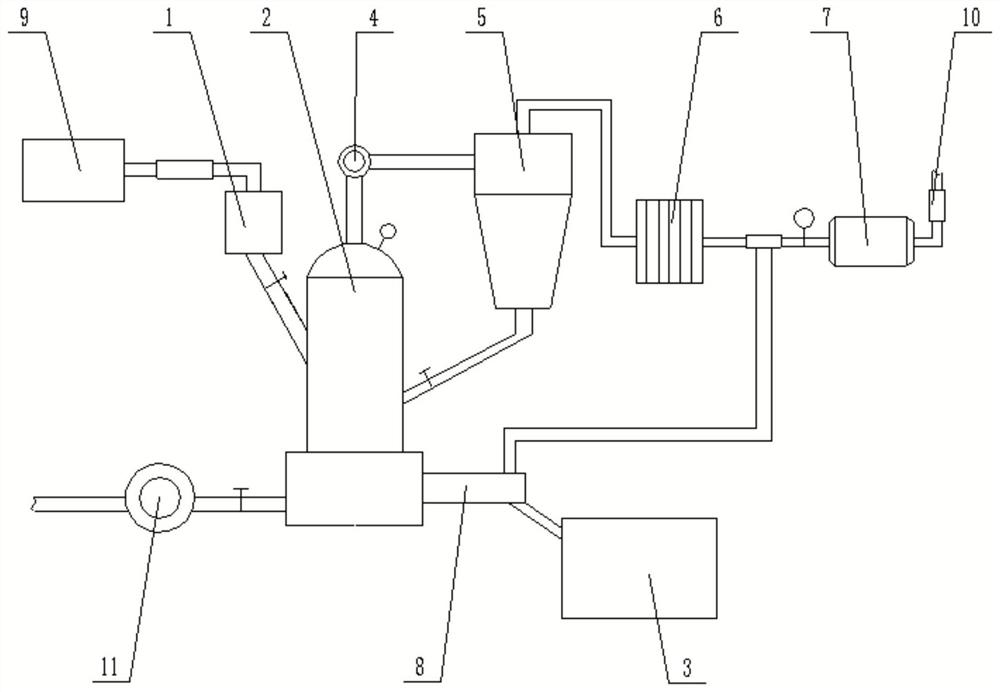

Image

Examples

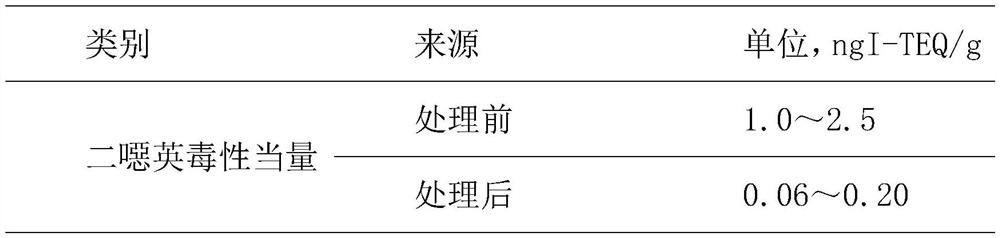

Embodiment 1

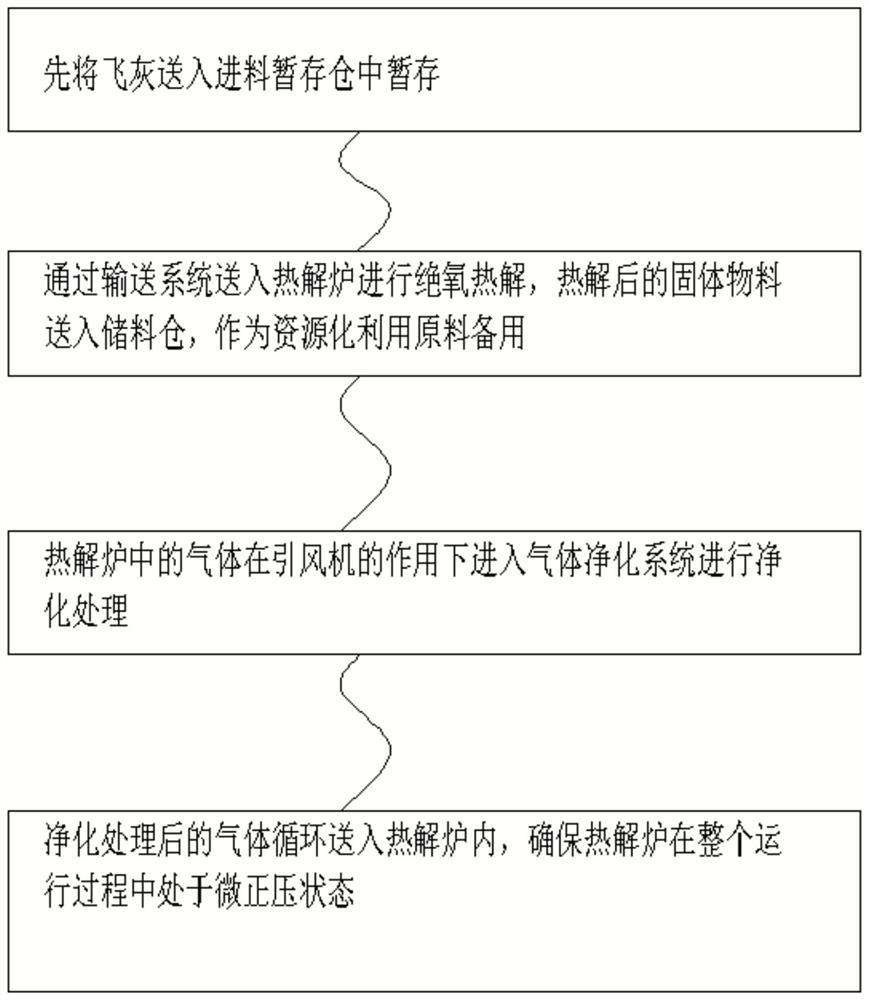

[0035] Using the waste incineration fly ash pyrolysis technology of the present application to treat fly ash from a waste power plant in Shanxi Province includes the following steps:

[0036] 1) Pre-storage of fly ash: The fly ash is sent into the temporary feed storage bin 1 by nitrogen transport, and the feed bin 9 is located at the upper end of the feed port of the pyrolysis furnace 2, ready for feeding;

[0037] 2) Gas replacement: After two nitrogen purging and replacement of the waste incineration fly ash pyrolysis system, a pressure-holding test was carried out on the pyrolysis furnace 2, and the pressure did not decrease significantly for 12 hours;

[0038] 3) Fly ash pyrolysis: after preheating the pyrolysis furnace 2 to 900°C, the fly ash in the feed temporary storage bin 1 is gradually sent into the pyrolysis furnace 2 for heating treatment. Heating, by adjusting the temperature of pyrolysis furnace 2 to control the temperature of fly ash in the furnace between 600℃...

Embodiment 2

[0046] Using the waste incineration fly ash pyrolysis technology of the present application to treat fly ash from a waste power plant in Hebei Province includes the following steps:

[0047] 1) Pre-storage of fly ash: The fly ash is sent into the temporary feed storage bin 1 by nitrogen transport, and the feed bin 9 is located at the upper end of the feed port of the pyrolysis furnace 2, ready for feeding;

[0048] 2) Gas replacement: After the waste incineration fly ash pyrolysis system is purged and replaced with nitrogen twice, the pressure holding test of the pyrolysis furnace 2 is carried out, and the pressure does not decrease significantly for 12 hours;

[0049] 3) Fly ash pyrolysis: after preheating the pyrolysis furnace 2 to 900°C, the fly ash in the feed temporary storage bin 1 is gradually sent into the pyrolysis furnace 2 for heating treatment. Heating, by adjusting the temperature of the pyrolysis furnace 2 to control the temperature of the fly ash in the furnace ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com