Surface roughening method of thin-wall metal shell implanted into human body

A metal shell and surface roughening technology, applied in the field of medical devices, can solve the problems of affecting the assembly and welding of the shell, easy intrusion of strong acid or high-speed sand into the boundary, and difficulty in ensuring product consistency, so as to ensure biocompatibility. and structural reliability, reliable structural strength, and the effect of reducing processing links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

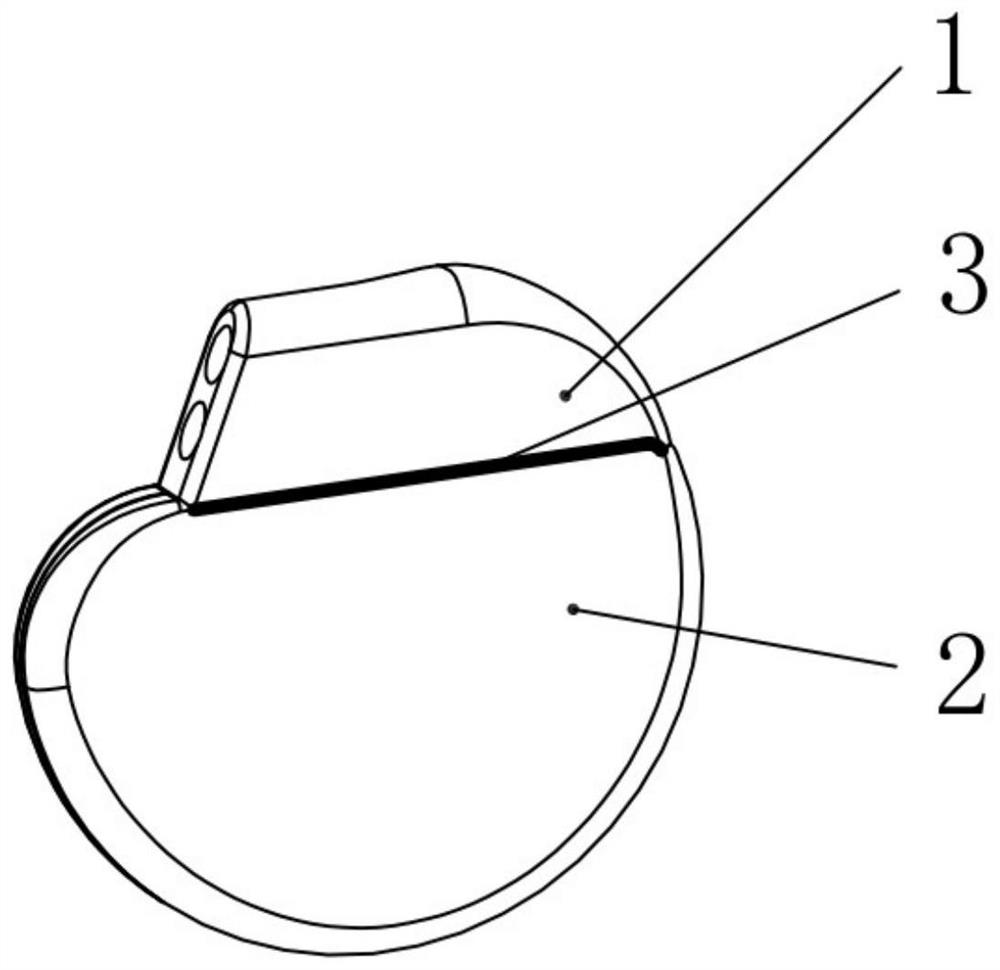

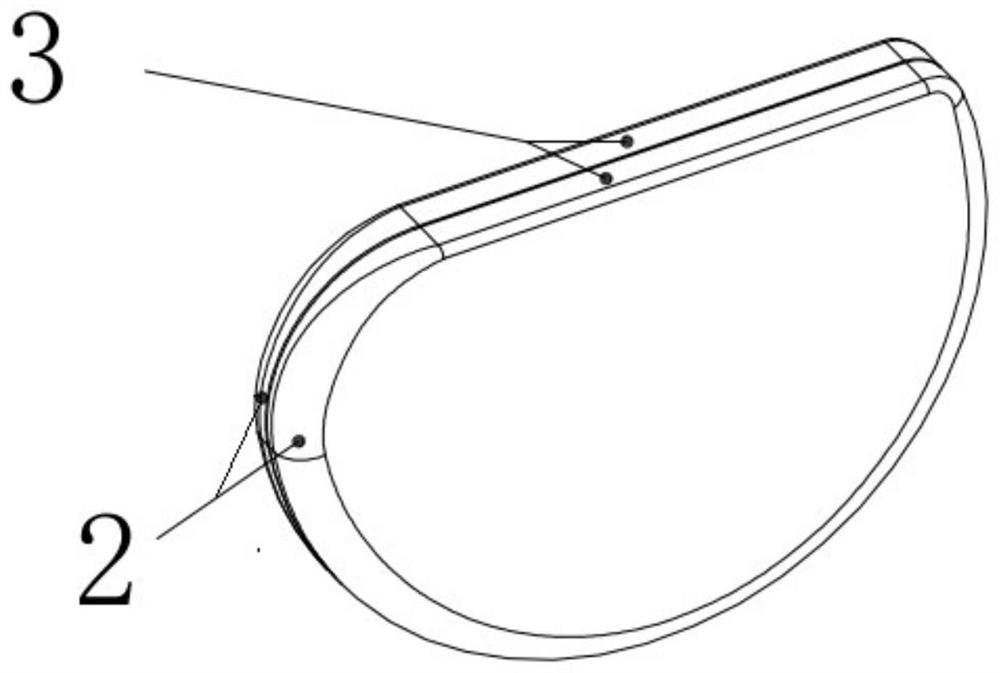

[0050] Such as Figure 4 As shown, a method for roughening the surface of a thin-walled metal shell implanted in a human body comprises the following steps:

[0051] (1) The metal shell is obtained by stamping and forming, and the metal surface to be treated is cleaned to remove oil stains and impurities on the surface.

[0052] The material of the metal shell is pure titanium TA1, and the cleaning method is as follows: soak the shell in a cleaning agent and treat it with ultrasonic waves for 2 minutes, take it out, and dry it naturally; the cleaning agent is anhydrous isopropanol.

[0053] (2) Fix the metal shell to the processing table, set the processing area, adjust the laser process parameters, focus on the surface to be processed, start the laser to scan the metal surface, make the surface roughen, and cool naturally.

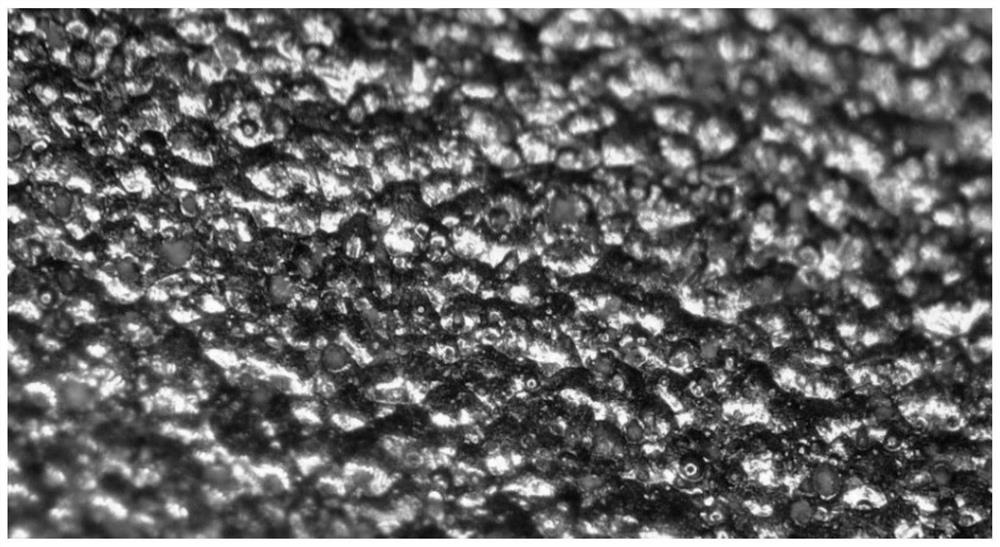

[0054] Laser process parameters: power 10W, scanning speed 100mm / s, scanning frequency 100kHz, spot diameter about 0.01mm. The surface roughness of the...

Embodiment 2

[0058] A method for roughening the surface of a thin-walled metal shell implanted in a human body, comprising the following steps:

[0059] (1) The metal shell is obtained by stamping and forming, and the metal surface to be treated is cleaned to remove oil stains and impurities on the surface.

[0060] The material of the metal shell is titanium alloy TC4; the cleaning method is as follows: soak the shell in the cleaning agent and ultrasonically treat it for 4 minutes, take it out, and dry it naturally; the cleaning agent is absolute alcohol.

[0061] (2) Fix the metal shell to the processing table, set the processing area, adjust the laser process parameters, focus on the surface to be processed, start the laser to scan the metal surface, make the surface roughen, and cool naturally.

[0062] Laser process parameters: power 50W, scanning speed 250mm / s, scanning frequency 80kHz, spot diameter about 0.01mm. The surface roughness of the shell after laser treatment is Ra1.2um. ...

Embodiment 3

[0066] A method for roughening the surface of a thin-walled metal shell implanted in a human body, comprising the following steps:

[0067] (1) The metal shell is obtained by stamping and forming, and the metal surface to be treated is cleaned to remove oil stains and impurities on the surface.

[0068] The material of the metal shell is stainless steel 316L; the cleaning method is as follows: soak the shell in the cleaning agent and ultrasonically treat it for 2 minutes, take it out, and dry it naturally; the cleaning agent is 75% medical alcohol.

[0069] (2) Fix the metal shell to the processing table, set the processing area, adjust the laser process parameters, focus on the surface to be processed, start the laser to scan the metal surface, make the surface roughen, and cool naturally.

[0070] Laser process parameters: power 100W, scanning speed 800mm / s, scanning frequency 50kHz, spot diameter about 0.01mm. The surface roughness of the shell after laser treatment is Ra2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com