Fixing device for aluminum thin-wall part processing and processing method of fixing device

A thin-walled part processing and fixing device technology, applied in positioning devices, manufacturing tools, metal processing equipment and other directions, can solve the problems of workpiece and gypsum detachment, workpiece damage, lack of adhesion between gypsum and workpiece, etc. The effect of reducing the breakage rate and avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

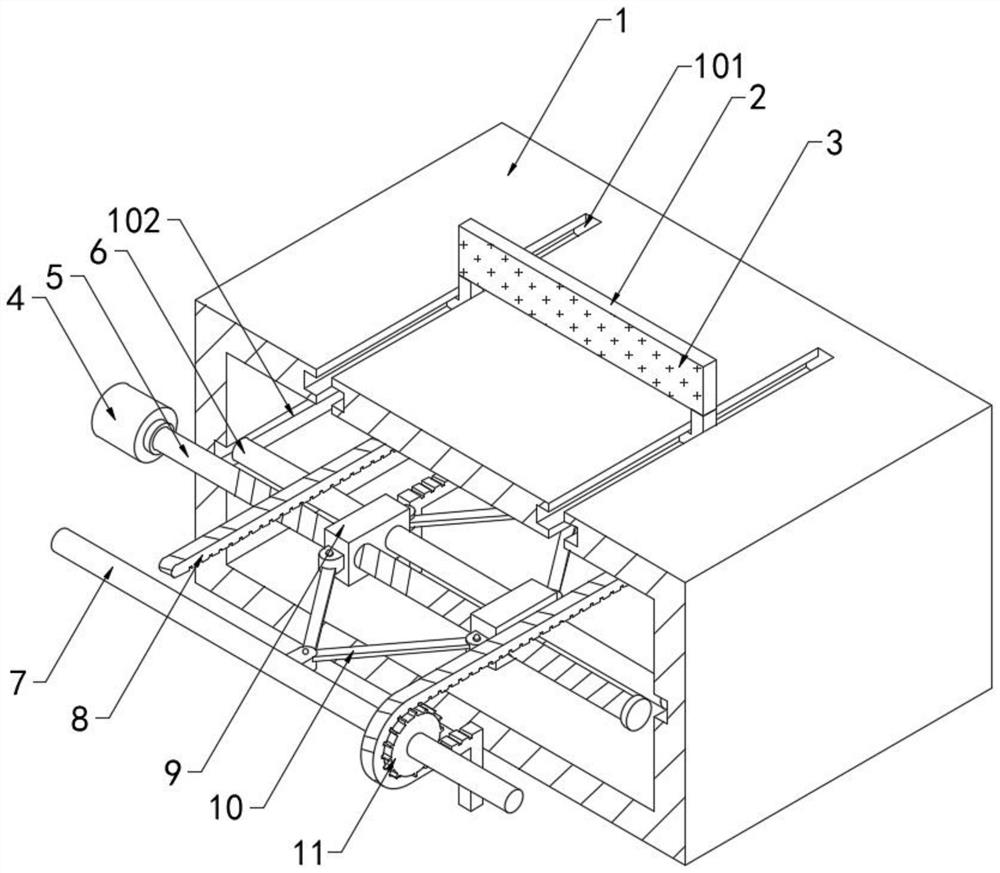

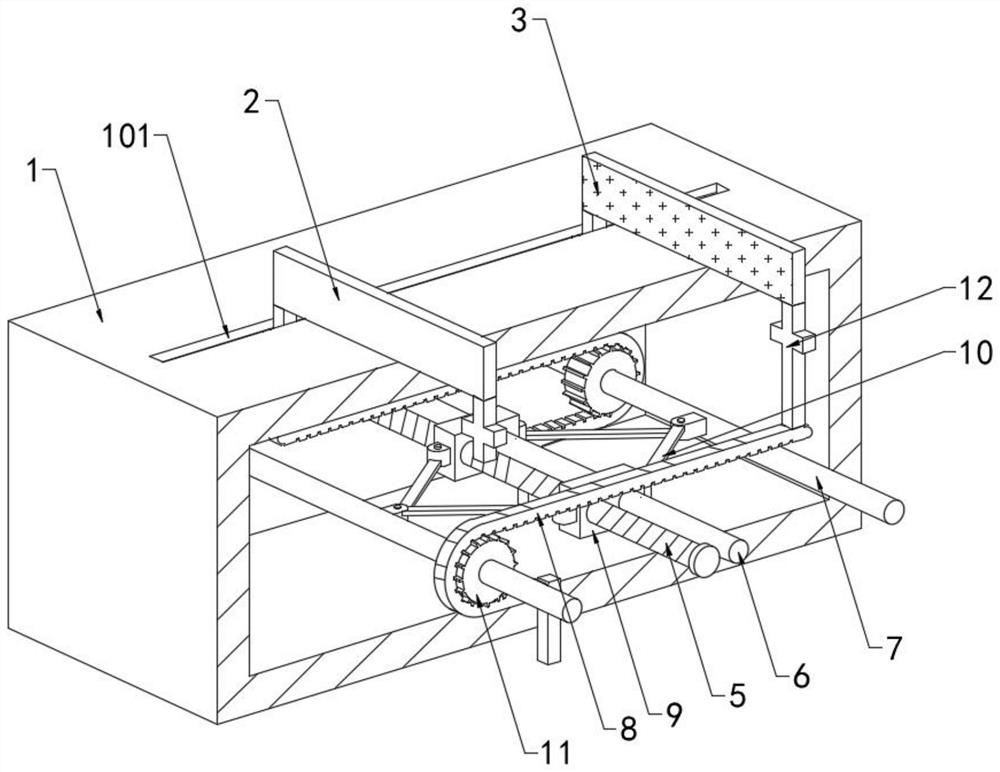

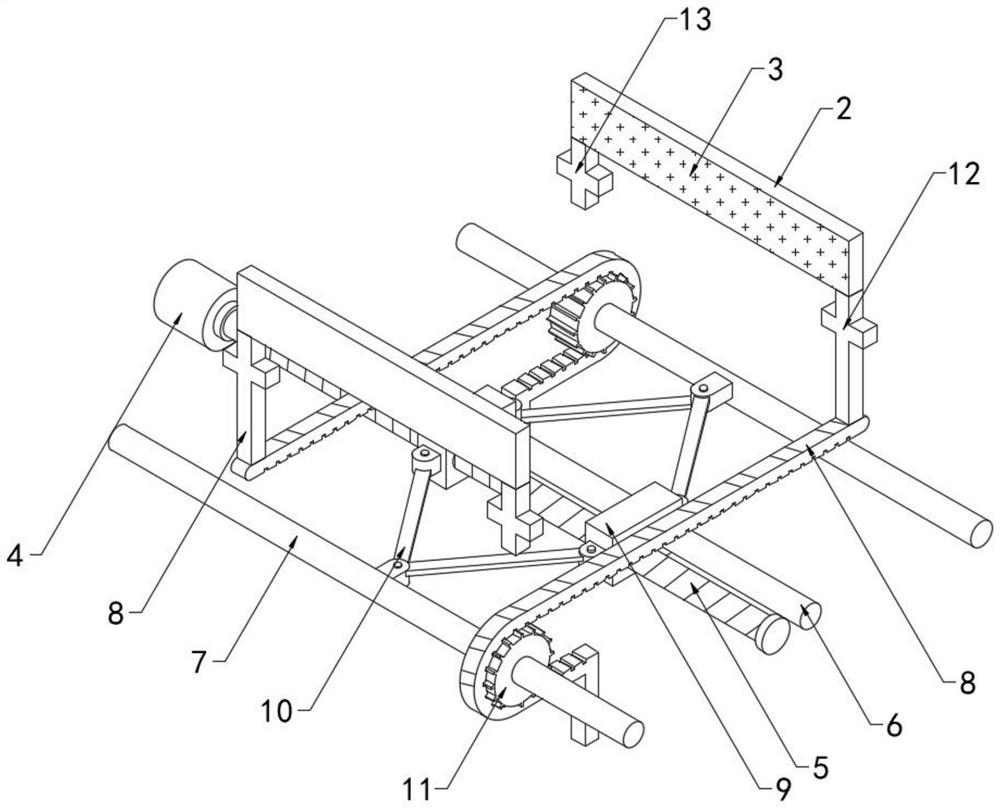

[0042] see Figure 1-6 , the present invention provides a technical solution: a fixing device for processing aluminum thin-walled parts, including a workbench 1, roller shafts 7 are arranged on both sides inside the workbench 1, and a drive for driving the roller shaft 7 to move closer or farther horizontally Structure, the inner surface wall on both sides of the workbench 1 is provided with a second chute 102 slidingly connected with the roller shaft 7, one end of the roller shaft 7 on both sides is rotated and installed with a gear 11, and the outer sides of the gears 11 at both ends are meshed and connected with a tooth shape Belt 8, one end of the toothed belt 8 is fixedly connected to the workbench 1, and the other end is fixedly connected to the first cross slider 12, and the two first cross sliders 12 are located at both ends of the diagonal line of the workbench 1, The splint 2 is fixedly connected to the top of the first cross slider 12 on both sides, the inner side o...

Embodiment 2

[0056] see Figure 1-6 , the present invention provides a technical solution: a fixing device for processing aluminum thin-walled parts, including a workbench 1, roller shafts 7 are arranged on both sides inside the workbench 1, and a drive for driving the roller shaft 7 to move closer or farther horizontally Structure, the inner surface wall on both sides of the workbench 1 is provided with a second chute 102 slidingly connected with the roller shaft 7, one end of the roller shaft 7 on both sides is rotated and installed with a gear 11, and the outer sides of the gears 11 at both ends are meshed and connected with a tooth shape Belt 8, one end of the toothed belt 8 is fixedly connected to the workbench 1, and the other end is fixedly connected to the first cross slider 12, and the two first cross sliders 12 are located at both ends of the diagonal line of the workbench 1, The splint 2 is fixedly connected to the top of the first cross slider 12 on both sides, the inner side o...

Embodiment 3

[0070] see Figure 1-6 , the present invention provides a technical solution: a fixing device for processing aluminum thin-walled parts, including a workbench 1, roller shafts 7 are arranged on both sides inside the workbench 1, and a drive for driving the roller shaft 7 to move closer or farther horizontally Structure, the inner surface wall on both sides of the workbench 1 is provided with a second chute 102 slidingly connected with the roller shaft 7, one end of the roller shaft 7 on both sides is rotated and installed with a gear 11, and the outer sides of the gears 11 at both ends are meshed and connected with a tooth shape Belt 8, one end of the toothed belt 8 is fixedly connected to the workbench 1, and the other end is fixedly connected to the first cross slider 12, and the two first cross sliders 12 are located at both ends of the diagonal line of the workbench 1, The splint 2 is fixedly connected to the top of the first cross slider 12 on both sides, the inner side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com