Nozzle for liquid beam electroforming square-section metal structure

A metal structure and nozzle technology, applied in electroforming, electrolysis process, etc., can solve the problems of high liquid beam center, reduced surface area, strong impact of cathode base, etc., to achieve small liquid resistance, reduce surface tension and liquid resistance , The effect of surface tension is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

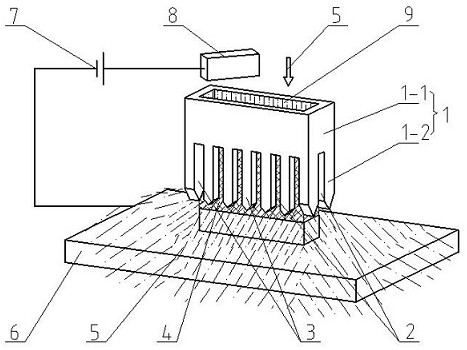

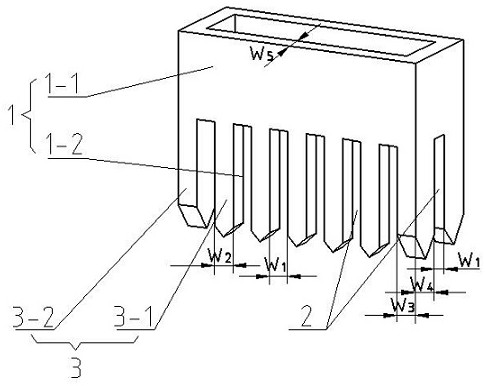

[0020] Combine below figure 1 , figure 2 , image 3 The specific implementation process of the invention "a nozzle for liquid beam electroforming square cross-section metal structure" is described in detail.

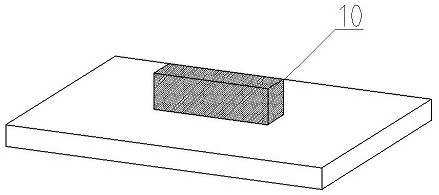

[0021] A nozzle for liquid beam electroforming square section metal structure according to the present invention, such as figure 2 As shown, the nozzle 1 is in the shape of a hollow square tube with a rectangular cross-section and equal wall thickness. The length of the long side of the rectangular nozzle 1 is 2.08mm, the length of the short side is 0.8mm, and the wall thickness is w 5 It is 160 μm, and there is an upper guide section 1-1 and a lower guide section 1-2 with micro-grid slits 2 and micro-grid 3 around it. The micro-grids 3 include 10 central micro-grids 3-1 located in the middle of the two long sides of the nozzle 1 and 4 corner micro-grids 3-2 located at the two corners of the two short sides of the nozzle 1. The height of the upper diversion sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com