Refrigerator

A technology for refrigerators and cabinets, which is applied in the field of refrigerated storage. It can solve problems such as large air duct resistance, refrigeration performance deviation, flow or performance differences, etc., to reduce the length of heat transfer, reduce the length of heat transfer, and reduce the risk of condensation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

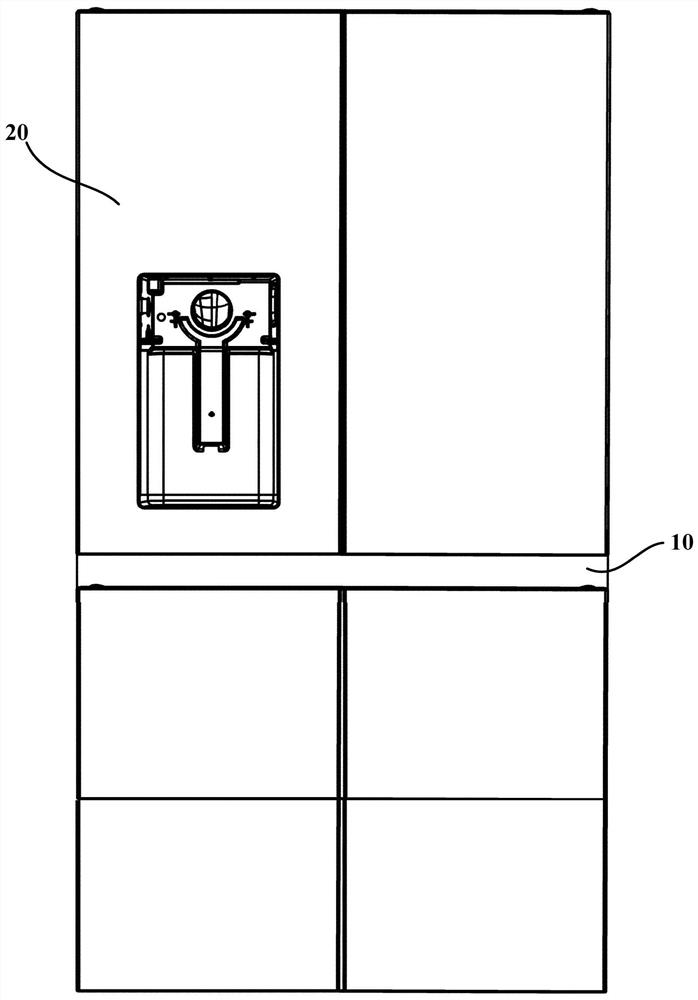

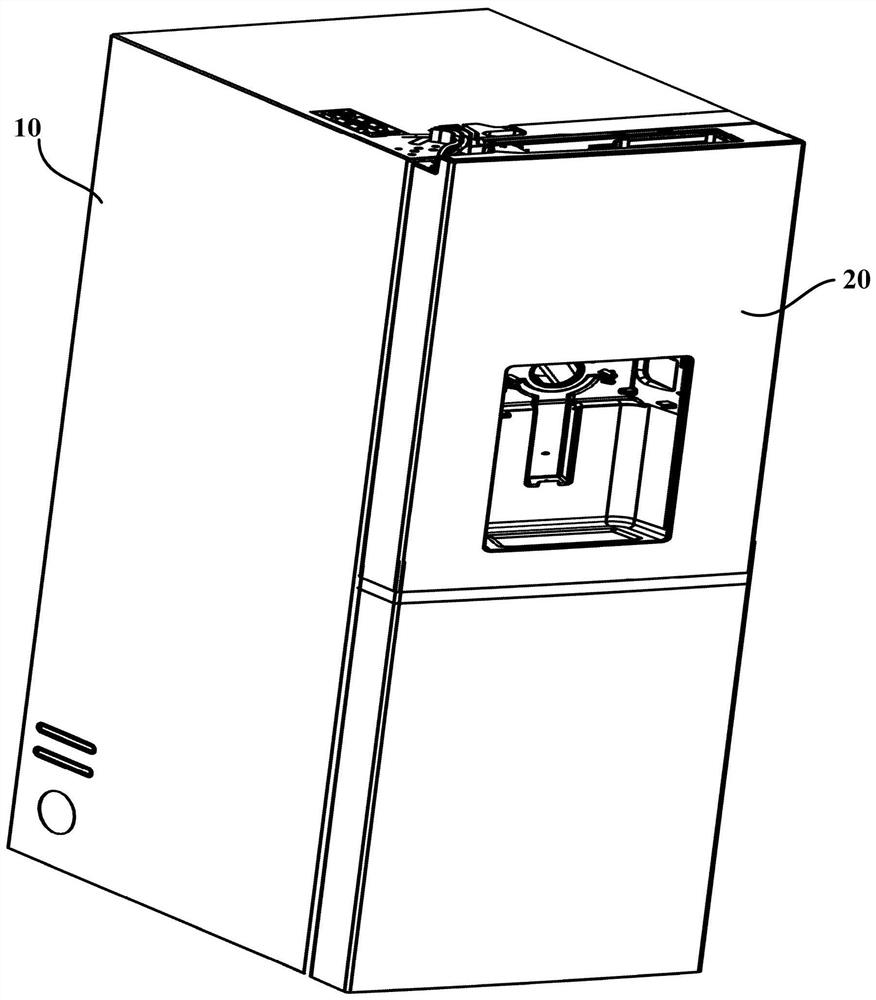

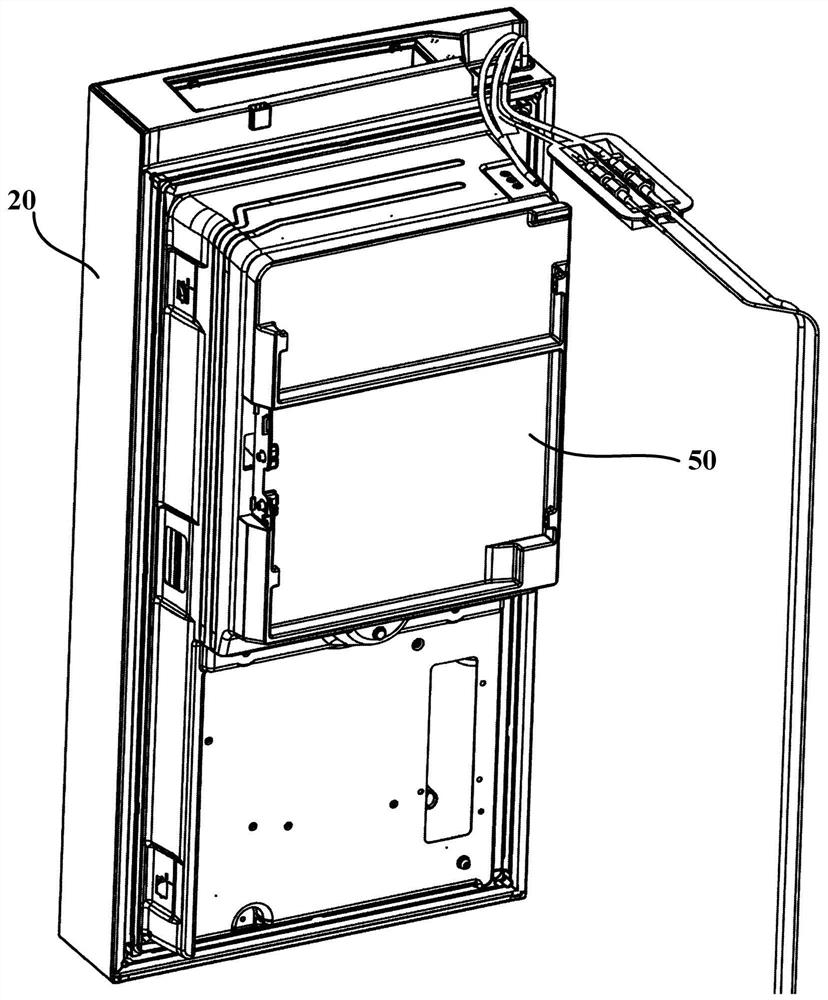

[0036] figure 1 is a schematic structural diagram of a refrigerator according to an embodiment of the present invention. like figure 1 shown and refer to Figure 2 to Figure 7 , The embodiment of the present invention provides a refrigerator. The refrigerator includes a box body 10, a door body 20 and a refrigeration system. The box body 10 is provided with storage compartments, such as a first storage compartment, a second storage compartment and a third storage compartment. The first storage compartment may be a refrigerated compartment, and the storage temperature is generally between 2°C and 10°C, preferably between 3°C and 8°C. The second storage compartment can be a freezer compartment, and the temperature range is generally -14°C to -22°C. The third storage compartment can be a temperature-changing compartment, and the temperature inside it can be adjusted according to demand, so as to store suitable food. The door 20 is configured to open and close the first stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com