Water pump service life reliability acceleration test method

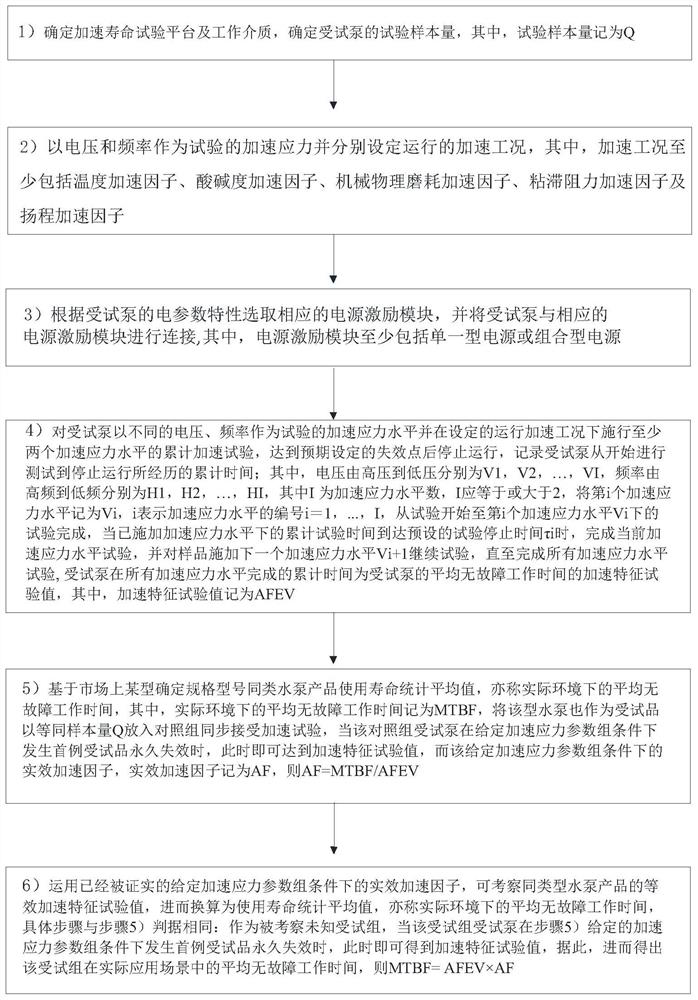

A test method and reliability technology, applied in the field of water pumps, can solve the problems of large time and economic cost, unfavorable water pump development, etc., and achieve the effect of reducing test cost, shortening test time and improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

test approach 1

[0044] Test scheme 1: The test sample size is 5 water pump test items. Accelerated stress level adopts ①AC254V / 50Hz (0~720hrs), ②AC254V / 45Hz (720~1440hrs), ③AC254V / 60Hz (1440~2880hrs) three accelerated stress levels. The acceleration condition of the set operation is as follows: the maximum working condition head stress: 2m. Temperature stress: The liquid temperature of the working medium (water or oil) is 45°C. pH stress: pH=7.0. Physical and mechanical friction and abrasion stress: sediment mixture 3.0kg / 100L working fluid. Viscous resistance stress: The dosage of viscous substance in polymer resin coating waste liquid is 1.5kg / 100L working fluid.

[0045] Test results: the cumulative test time of the first accelerated stress level (AC254V / 50Hz) is 720hrs, the cumulative test time of the second accelerated stress level (AC254V / 45Hz) is 1440hrs, and the third accelerated stress level (AC254V / 60Hz) The accumulative test time is 2880hrs, and the accelerated feature test val...

test approach 2

[0046]Test scheme 2: The test sample size is 7 water pump test items. Accelerated stress level adopts ①AC254V / 50Hz (0~1200hrs) and ②AC240V / 50Hz (1200~2160hrs) two accelerated stress levels. The acceleration condition of the set operation is as follows: the maximum working condition head stress: 2m. Temperature stress: working medium (water or oil) liquid temperature is 50°C. pH stress: pH=6.0. Physical and mechanical friction and abrasion stress: sediment mixture 4.0kg / 100L working fluid. Viscous resistance stress: The dosage of viscous substance in polymer resin coating waste liquid is 2.0kg / 100L working fluid.

[0047] Test results: the accumulative test time of the first accelerated stress level (AC254V / 50Hz) is 1200hrs, the accumulative test time of the second accelerated stress level (AC240V / 50Hz) is 2160hrs, and the mean time between failure (MTBF) of the screening standard Accelerated characteristic test value (AFEV): The end point of the accelerated life test is 21...

test approach 3

[0048] Test scheme 3: The test sample size is 11 water pump test items. Accelerated stress level adopts ①AC254V / 50Hz (0~360hrs), ②AC207V / 50Hz (360~720hrs), ③AC240V / 50Hz (720~1440hrs) three accelerated stress levels. The acceleration condition of the set operation is as follows: the maximum working condition head stress: 2m. Temperature stress: the liquid temperature of the working medium (water or oil) is 55°C. pH stress: pH=10.0. Physical and mechanical friction and abrasion stress: sediment mixture 3.0kg / 100L working fluid. Viscous resistance stress: The dosage of viscous substance in polymer resin coating waste liquid is 1.5kg / 100L working fluid.

[0049] Test results: the cumulative test time of the first accelerated stress level (AC254V / 50Hz) is 360hrs, the cumulative test time of the second accelerated stress level (AC207V / 50Hz) is 720hrs, and the third accelerated stress level (AC240V / 50Hz) The cumulative test time is 1440hrs, and the accelerated characteristic test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com