Field returning machine capable of embedding materials into soil

A technology of forehearth and mixing cavity, which is applied to the field of returning machines with embedded materials into the soil, can solve the problems of prolonging the decay time of straw, reducing the efficiency of straw use, and reducing the germination rate of seeds, etc., and achieves a high degree of automation, convenient operation, and low The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

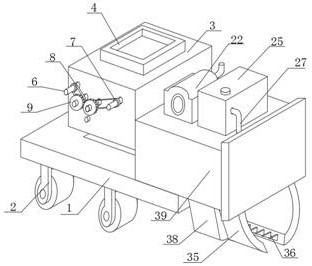

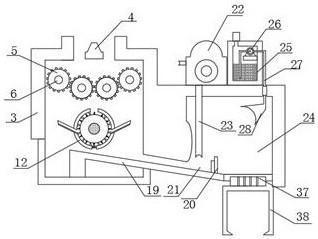

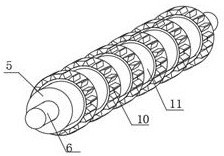

[0029] Such as Figure 1-5 As shown, a field returning machine for embedding materials into the soil includes a vehicle chassis 1 and a driving wheel 2, a crushing box 3 is installed on the upper end of the vehicle chassis 1, and the top of the crushing box 3 is provided with a splash-proof port 4, and the splash-proof port Four groups of crushing rollers 5 are arranged below 4, roller shafts 6 are arranged at both ends of the crushing rollers 5, and sprockets 7 are sleeved on the roller shafts 6 at one end of each group of crushing rollers 5, and two adjacent groups of sprockets 7 Connected by a chain 8, gears 9 are installed on the roller shafts 6 at one end of the two sets of crushing rollers 5 in the middle, and are meshed with each other. The roller surfaces of the crushing rollers 5 are equidistantly provided with ring roller blade groups 10, and the adjacent ring roller blade groups There is a broken gap 11 reserved between 10;

[0030] The four groups of crushing roll...

Embodiment 2

[0036] In the actual design process, the first motor and the second motor in Embodiment 1 are combined, and a single motor is used to cooperate with the gear transmission system to complete the crushing and crushing operations.

Embodiment 3

[0038] In order to keep the digging action of the arc-shaped digging shovel 35 synchronized with the time of discharging material from the feeding square pipe 38, a PLC intelligent controller needs to be installed to manage the operation of the air pump 22, the water pump 26 and the cylinder 30. Match the three.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com