Integrated dust removal and desulfurization tower

The technology of desulfurization tower and tower body is applied in the field of integrated dust removal and desulfurization tower, which can solve the problems of poor effect of dust removal and desulfurization tower, and achieve the effect of good contact and increase of contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

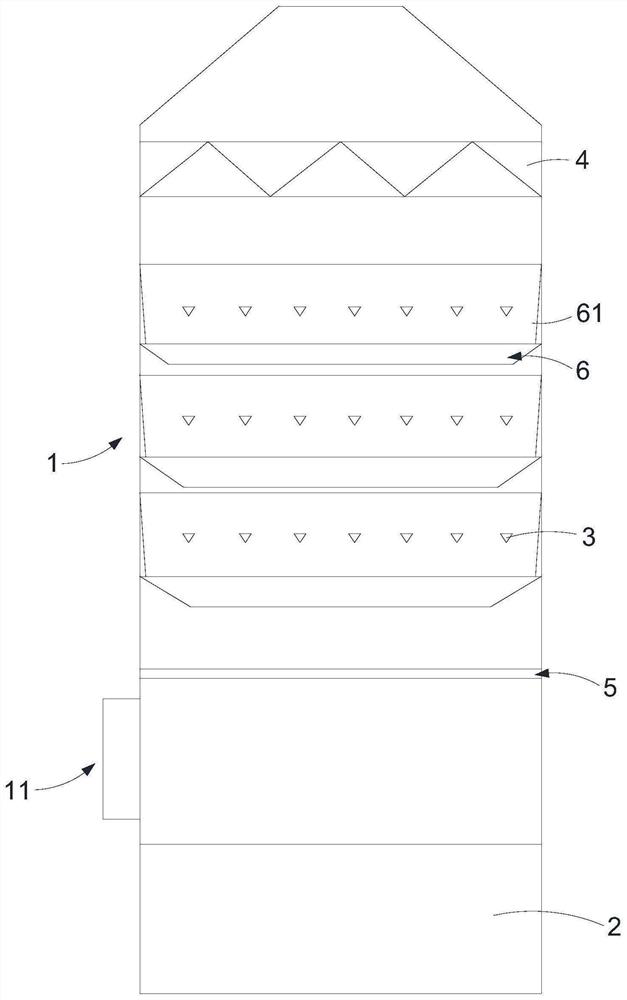

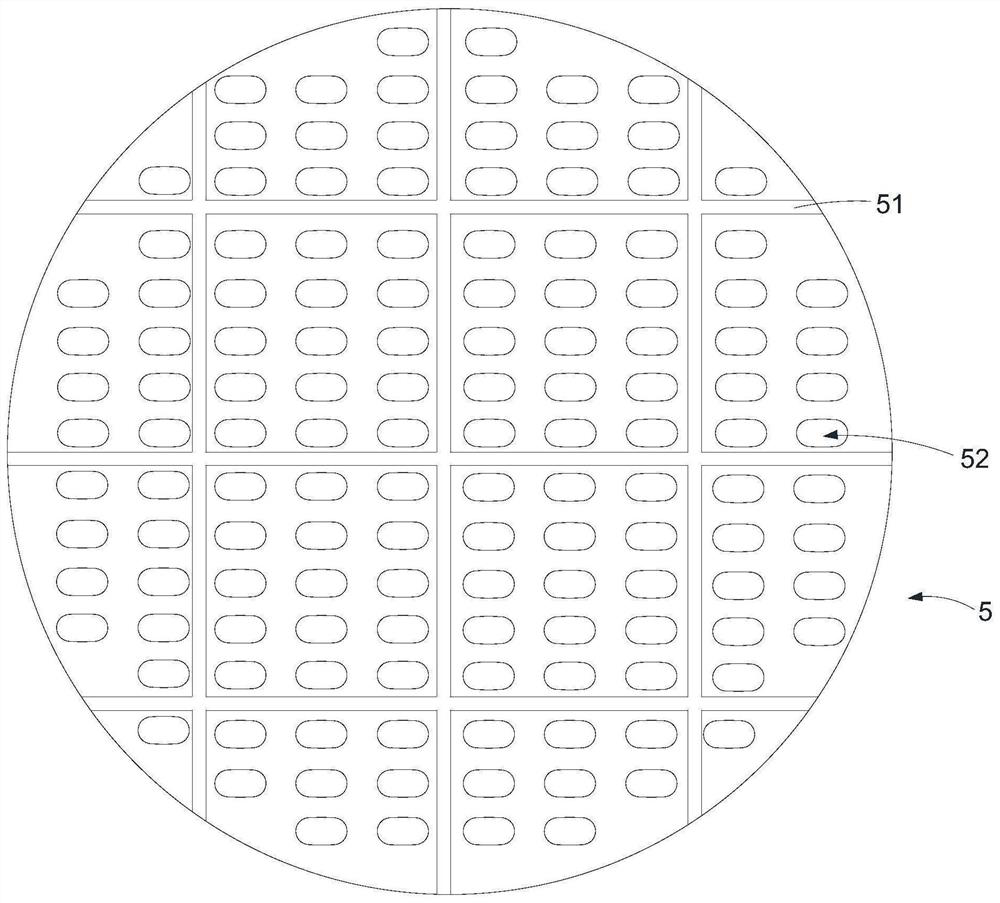

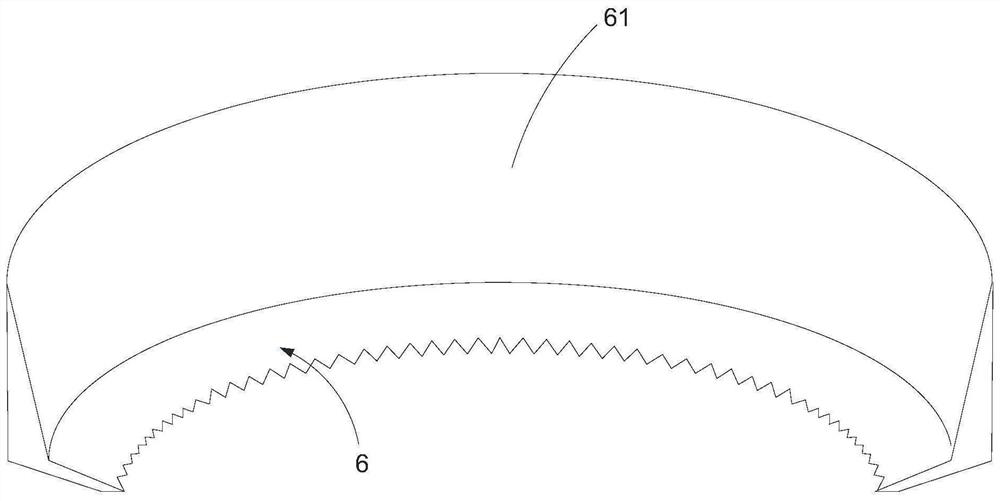

[0027] like Figure 1-Figure 3 As shown, the present invention provides an integrated dust removal and desulfurization tower, including a tower body 1 and a slurry pool 2, a spray layer and a demister layer 4 arranged inside the tower body 1 and distributed sequentially from bottom to top. A synergistic tray 5 is also arranged inside the integrated dust removal and desulfurization tower. The synergistic tray 5 is arranged between the slurry tank 2 and the spray layer. The booster tray 5 is provided with several partitions 51 . Several partitions 51 are connected to the upper surface of the booster tray 5 and divide the booster tray 5 into several pieces. The bottom of the booster tray 5 is provided with several oval through holes 52 . The booster tray 5 is located above the air inlet 11 of the tower body 1 .

[0028] When the integrated dedusting and desulfurization tower of the present invention is in use, flue gas enters the tower body 1 through the air inlet 11 and grad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com