Device and method for testing axial bearing performance of heavy-load planetary threaded roller bearing

A technology of roller bearing and test device, applied in the direction of mechanical bearing testing, etc., can solve problems such as load size limitation, and achieve the effect of easy installation and debugging, reasonable structure, and guaranteed strength and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

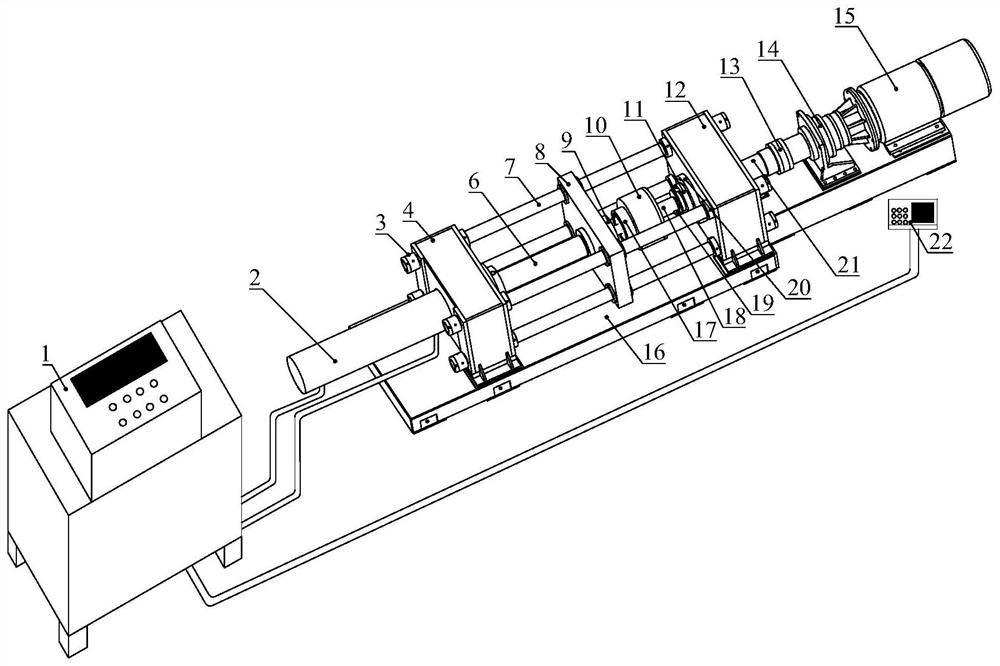

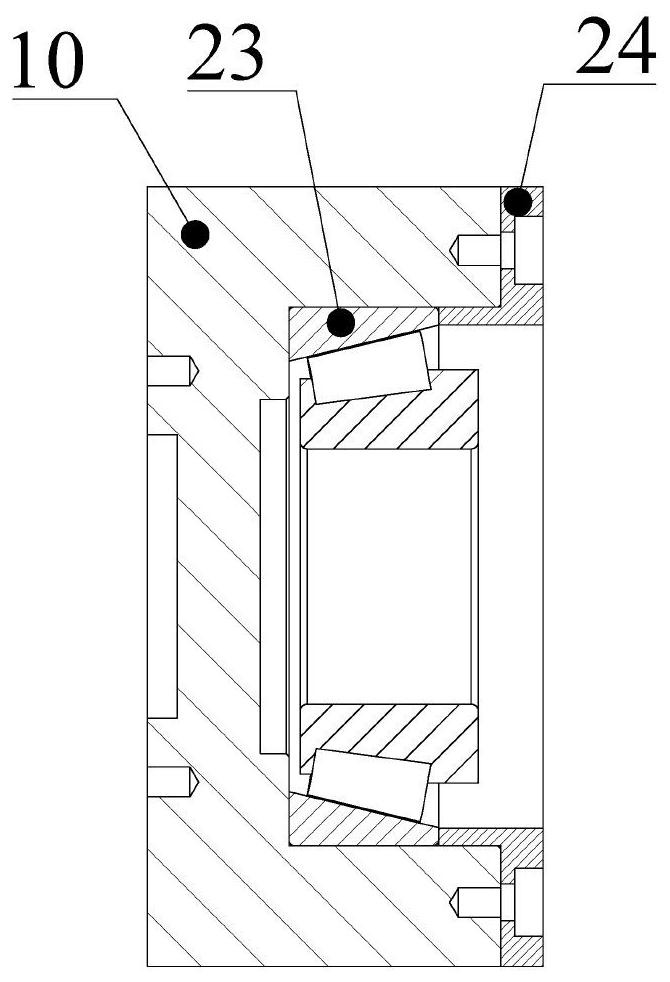

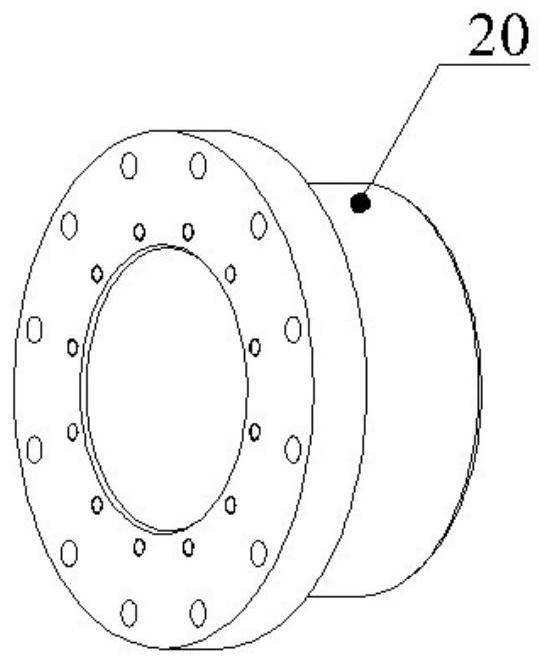

[0038] Specific implementation mode one: combine Figure 1-7 Description of this embodiment, the heavy-duty planetary threaded roller bearing axial load-bearing performance test device, which includes a base 16, a loading device, a three-beam and four-column structure, installation tooling, a drive system, and a measurement and control system, wherein the three-beam and four-column structure includes mutual The first fixed beam 4, the second fixed beam 12, the sliding beam 8, and four parallel and horizontally arranged first fixed beams 4, 12, and 4 are arranged parallel to each other vertically, and the first fixed beam 4 and the second fixed beam 12 are Fixedly installed on the base 16, the sliding beam 8 is located between the first fixed beam 4 and the second fixed beam 12 and is slidably fitted on the four guide bearing columns 7, and the two ends of the four guide bearing columns 7 are corresponding Fixed connection with the first fixed beam 4 and the second fixed beam 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com