Video pile safety management method, video pile based on regional state information and regional management method

A technology for safety management and regional status, applied in CCTV systems, indicating various open spaces in parking lots, traffic control systems for road vehicles, etc. To achieve the effect of reducing heat and light pollution, avoiding water vapor intrusion, and high fusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0103] The video pile safety management method includes the following steps:

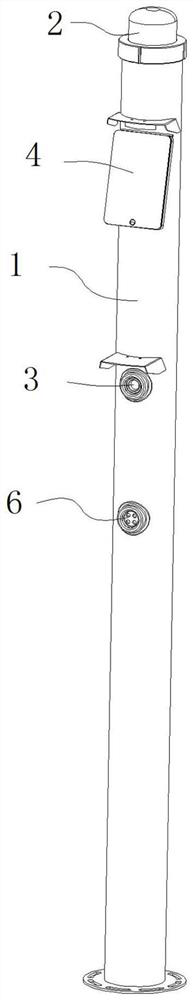

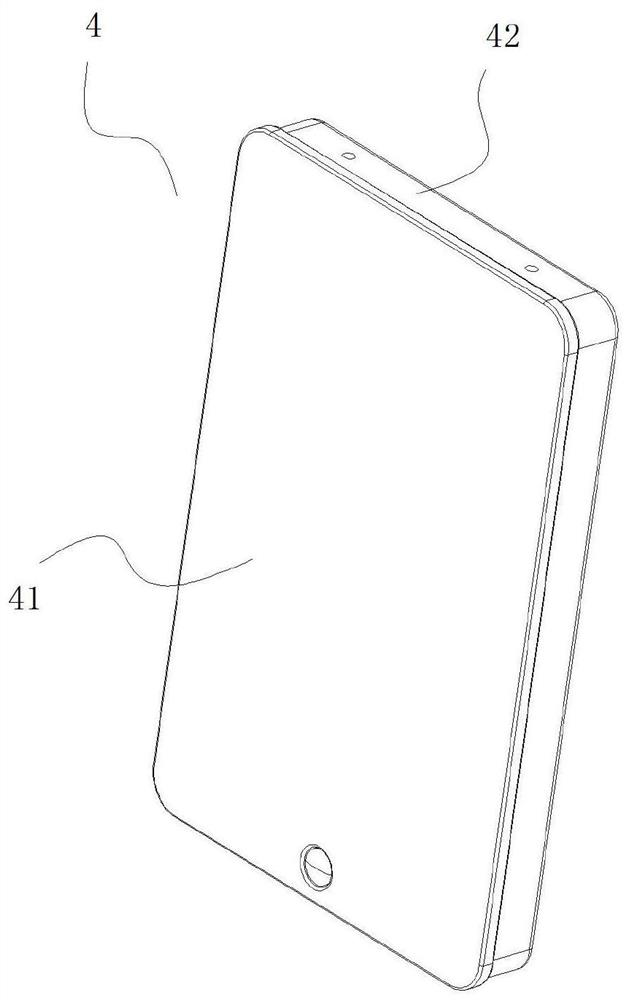

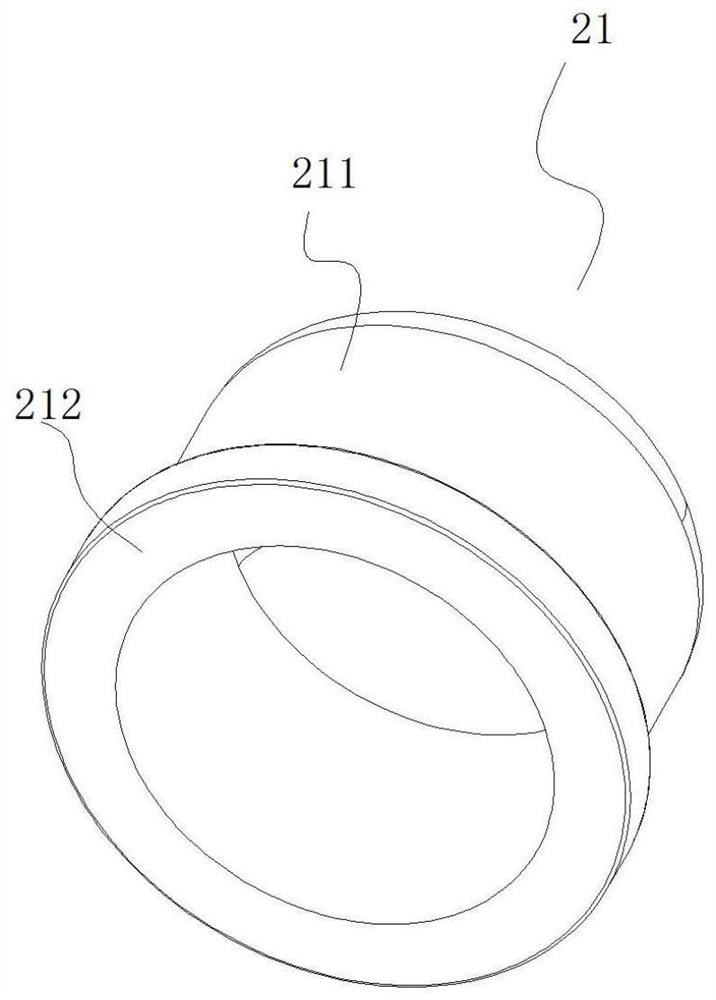

[0104] a. The cylinder body 11 of the video pile adopts the overall sealing and the pressurization method in the cylinder to maintain the set relative humidity and pressure value inside the video pile. The pressure increase method in the cylinder is to install a one-way inflation valve on the cylinder body 11 to cooperate The sealing member, the one-way inflation valve is kept connected with the inner cavity of the cylinder body 11 so as to realize the pressure maintaining inside the video pile. The controller inside the video pile will detect the relative humidity and relative pressure difference in real time, and at the same time control the relative pressure difference in the video pile within the range of 0.05bar.

[0105] b. Control the relative humidity inside the video post as a whole to 20%RH, where %RH is the unit of relative humidity.

[0106] c. The pressure difference sensor inside the ...

Embodiment 2

[0115] The difference between this embodiment and Embodiment 1 is: in step a, the relative pressure difference inside the video pile is controlled within the range of 0.2 bar. Step b controls the relative humidity inside the video pile to be 16%RH as a whole. In step c, when the detected relative pressure difference is in the range of 0.01bar or 0.4bar, it is determined that the micro-environment inside the video post is safe to fail, and the light-emitting component of the video post immediately sends out a warning. When the display and control system detects that the relative pressure difference is within the range of 0.05bar, Then turn to the following step d. In step d, when the relative humidity is 15%RH, it is determined that the security of the internal micro-environment of the video post is still valid at this time; when the relative humidity is 30%RH, it is determined that the security of the internal micro-environment of the video post is invalid at this time.

Embodiment 3

[0117] The difference between this embodiment and Embodiment 1 is: in step a, the relative pressure difference inside the video pile is controlled within the range of 0.15 bar. Step b controls the relative humidity inside the video pile to be 10%RH as a whole. In step c, when the detected relative pressure difference is in the range of 0.03bar or 0.5bar, it is determined that the micro-environment inside the video post is safe to fail, and the light-emitting component of the video post immediately sends out a warning. When the display and control system detects that the relative pressure difference is within the range of 0.1bar, Then turn to the following step d. In step d, when the relative humidity is 10%RH, it is determined that the security of the internal micro-environment of the video post is still valid at this time; when the relative humidity is 40%RH, it is determined that the security of the internal micro-environment of the video post is invalid at this time.

[01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com