Molecular dynamics based patterned surface construction method with anti-icing performance

A technology of molecular dynamics and patterned surfaces, applied in the fields of informatics, computational theoretical chemistry, design optimization/simulation, etc., can solve the problem that the microscopic mechanism cannot be well explained, the cost of time and material is large, and the accuracy of experimental conclusions is reduced. In order to achieve the effect of improving the utilization rate of computer resources, reducing the cost of computing time, and simplifying the difficulty of data processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

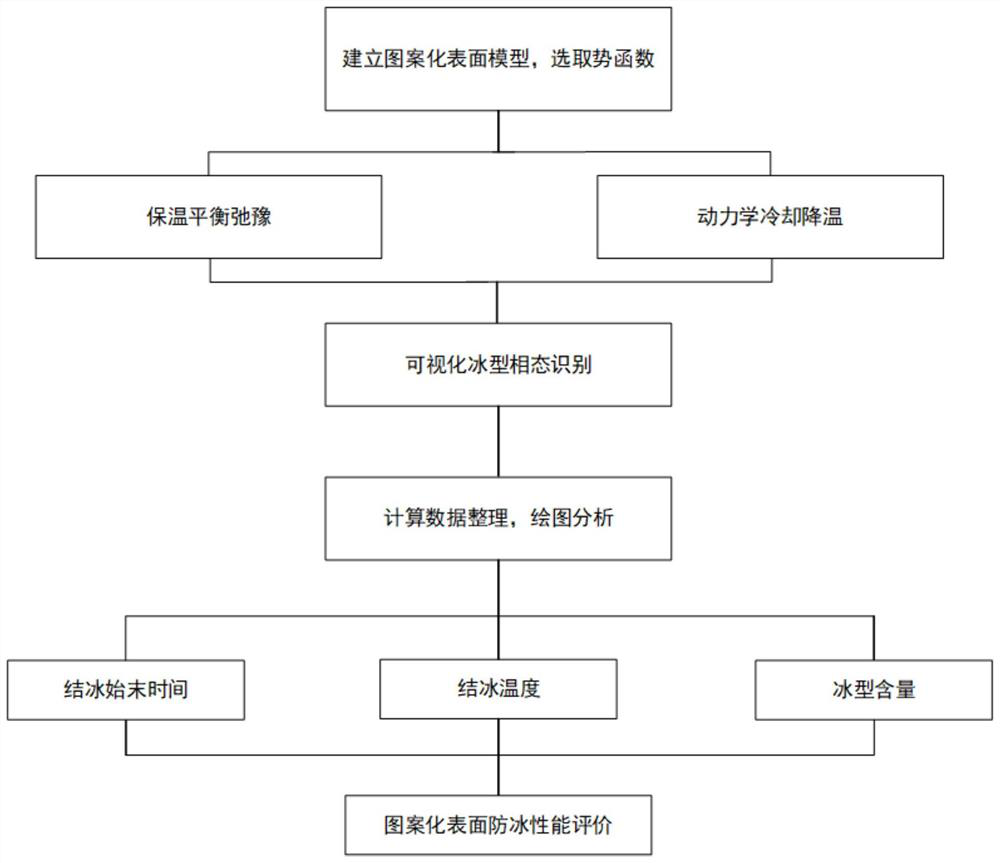

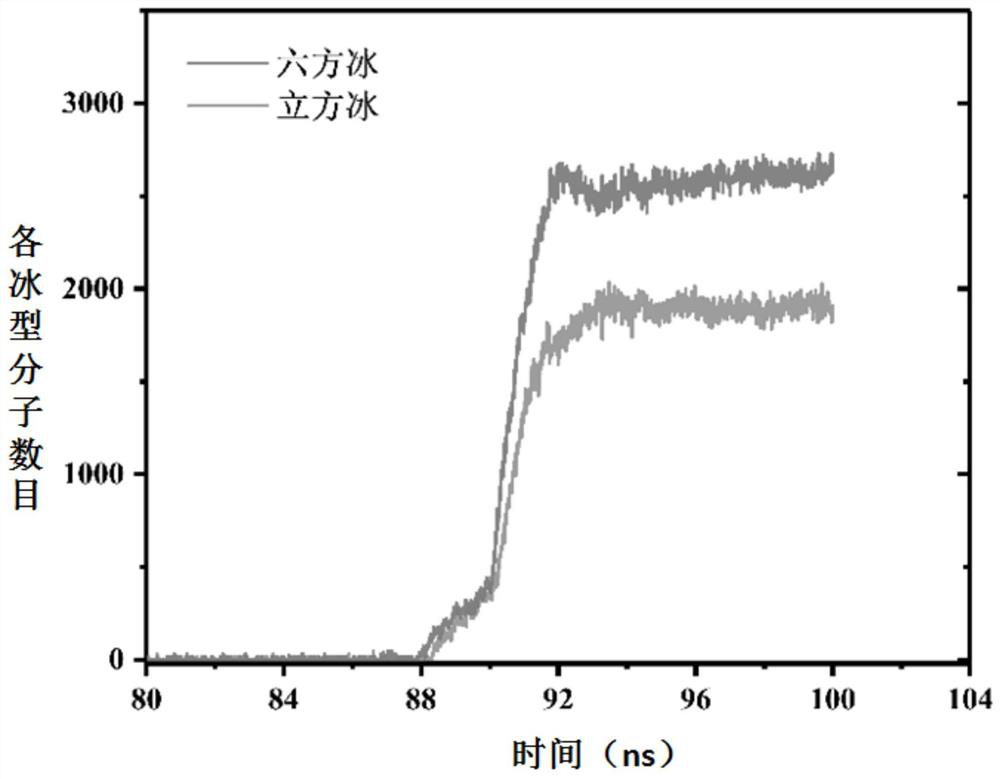

[0042] Such as figure 1 As shown, the patterned surface construction method with anti-icing performance based on molecular dynamics includes the following steps:

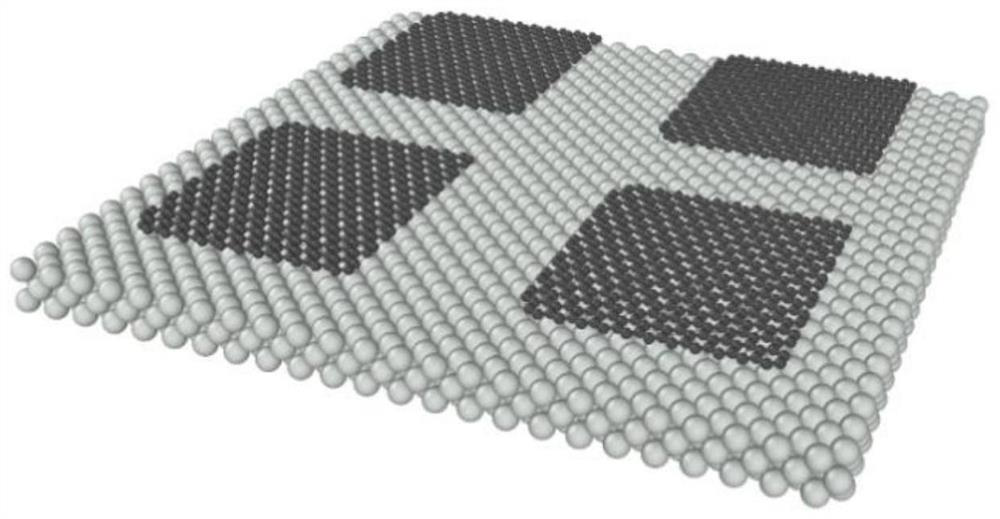

[0043] 1) Based on the molecular dynamics simulation software LAMMPS, the basic model of graphene nanosheets-substrate planes and water with different sizes and distributions is established: using a three-dimensional periodic box, first establish an infinite length and four atomic layer thickness on the XY axis The left and right substrate planes control the size of the graphene sheet and fix it on the substrate plane, the distance between the graphene sheet and the substrate plane is fixed, and the distribution of the graphene sheet on the substrate plane is controlled to be uniform (to meet the periodic boundary conditions ), fix the distance between the graphene sheets to obtain a patterned surface; fix all the atomic coordinates of the entire patterned surface, place water molecules on the surface, ensure that t...

Embodiment 2

[0061] The patterned surface construction method with anti-icing performance based on molecular dynamics is as follows:

[0062] 1) Based on the molecular dynamics simulation software LAMMPS, a metal aluminum substrate plane-single layer graphene surface configuration and water contact model was established. Using a three-dimensional periodic box, the size of the box is 9.74nm×9.76nm. First, an infinitely long aluminum plane substrate with a thickness of 3 atomic layers is established in the XY plane, and the (100) crystal plane is intercepted, and then graphene sheets are placed horizontally on the substrate plane. . The single-layer size of the graphene sheet is 2.85nm×3.27nm, the distance between the sheets is 2nm in the x direction, and 1.5nm in the y direction, and the distance between the graphene sheet and the substrate plane is 0.6nm and is evenly distributed on the plane. After the patterned surface is established, the atomic coordinates of the substrate and the grap...

Embodiment 3

[0070] The patterned surface construction method with anti-icing performance based on molecular dynamics is as follows:

[0071] 1) Based on the molecular dynamics simulation software LAMMPS, a metal aluminum substrate plane-single layer graphene surface configuration and water contact model was established. Using a three-dimensional periodic box, the size of the box is 9.74nm×9.76nm. First, an infinitely long aluminum plane substrate with a thickness of 3 atomic layers is established in the XY plane, and the (100) crystal plane is intercepted, and then graphene sheets are placed horizontally on the substrate plane. . The single-layer size of the graphene sheet is 2.85nm×3.27nm, the distance between the sheets is 2nm in the x direction, and 1.5nm in the y direction, and the distance between the graphene sheet and the substrate plane is 0.6nm and is evenly distributed on the plane. After the patterned surface is established, the atomic coordinates of the substrate and the grap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com