Powder rate measuring method and device

A measuring method and technology for measuring devices, which can be applied to measuring devices, inspection devices, furnace control devices, etc., can solve problems such as time required for analysis, delay in operation process, and problems with representativeness of sampling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

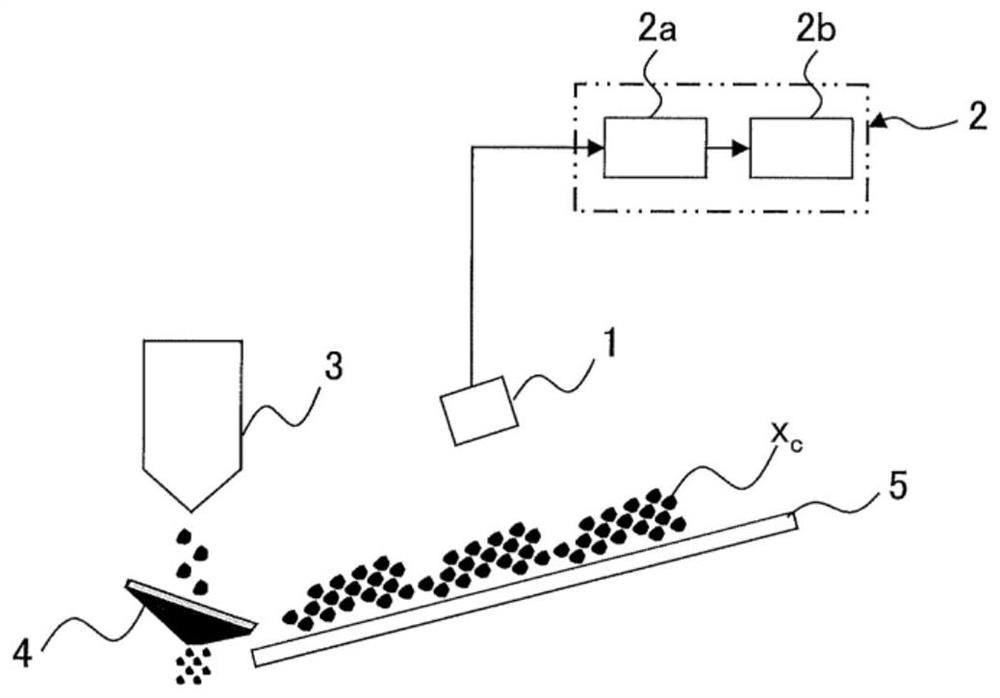

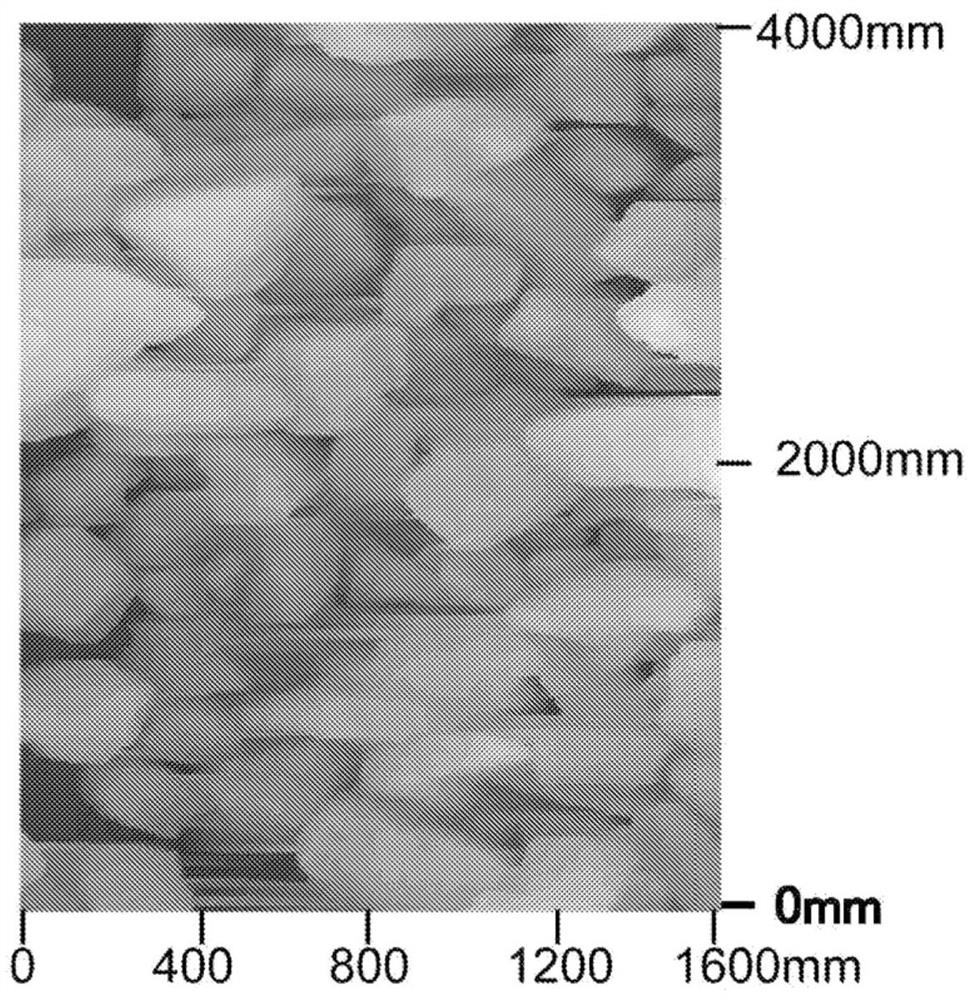

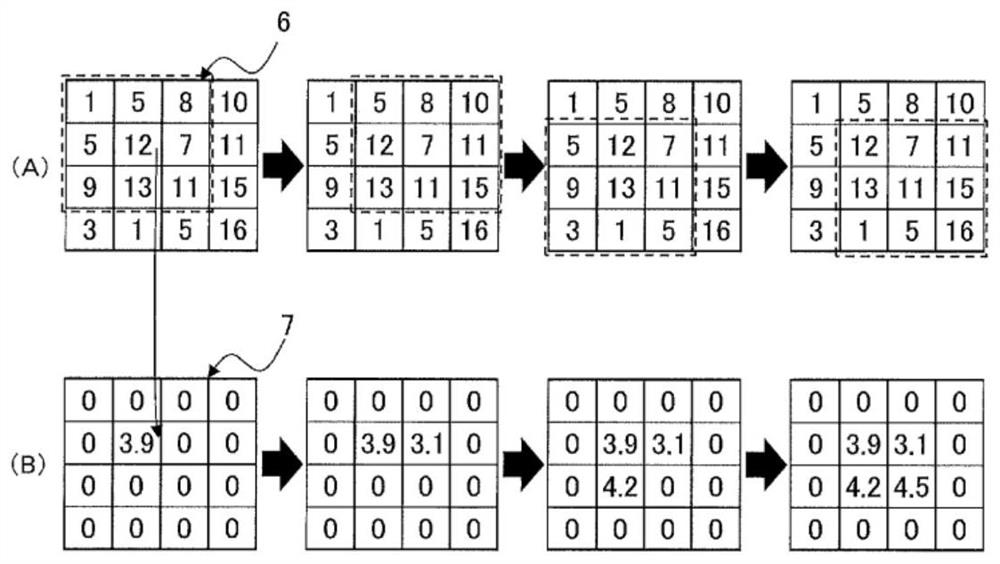

[0046] Method for determination of the powder of the present invention is a method of bulk powder substance is measured in the x, having the following steps based on the amount of powder adhered to the surface of the block of material x: distance using a distance measuring means for measuring a bulk material until the x steps S1, the feature quantity calculated in step S2 from the distance data obtained by the step S1, and S2 is calculated by the characteristic amount converting step flour yield S3.

[0047] Powder measuring device according to the present invention, further, provides a further embodiment of the method for determination of the powder, comprising: a distance measuring device, the distance x the measured bulk substance; and 2, 2a and converting means includes a calculation unit calculating means 2b feature amount, based on the distance calculation means 2a to the distance obtained by the measurement apparatus 1, the feature amount, the converting means 2b by the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com