Water-based one-component glass coating raw materials

A glass coating, one-component technology, applied in epoxy resin coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of glass coatings that need to be prepared on the spot, achieve a moist and smooth appearance, avoid waste, and withstand The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

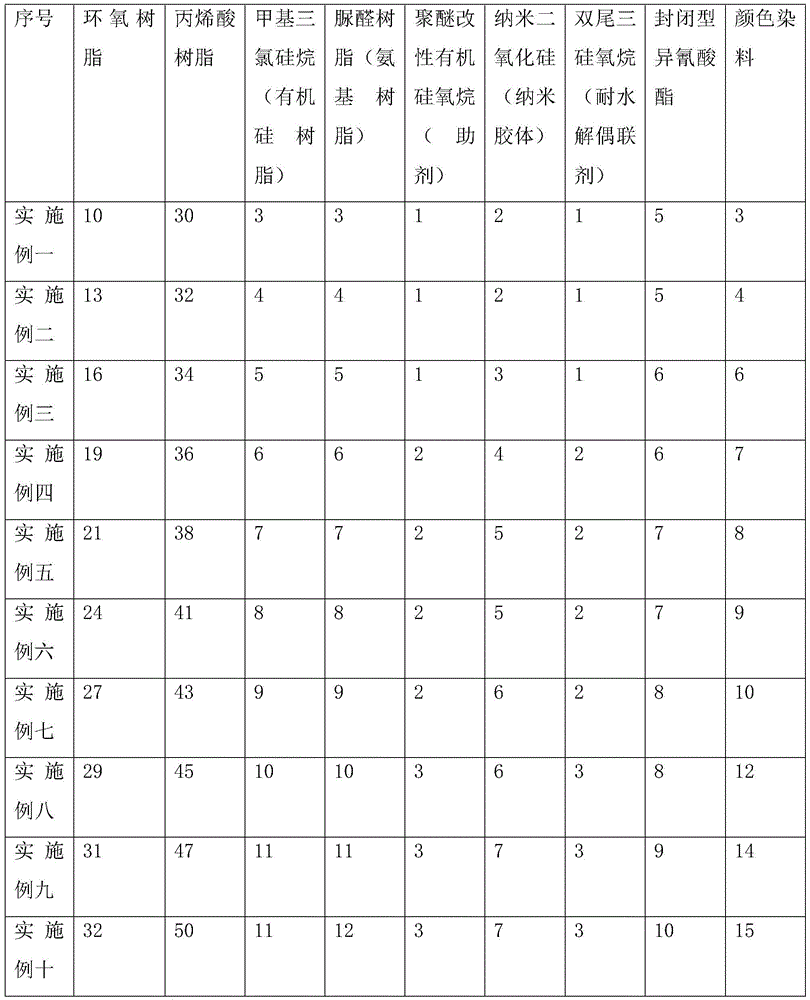

[0008] One, the water-based one-component glass paint raw material composition list in the following examples:

[0009]

[0010] Two, take embodiment seven as example below, describe the preparation method of water-based glass coating of the present invention in detail:

[0011] 1. First, adopt the cold blending method, put 27kg of epoxy resin, 43kg of acrylic resin, and 9kg of methyltrichlorosilane in deionized water, and use a conventional sanding, dispersing, and stirring multi-purpose machine to disperse at a high speed of 2500rpm for 10 minutes ;

[0012] 2. Then slowly add 9kg of urea-formaldehyde resin and continue stirring for 5 minutes;

[0013] 3. Slowly add 2kg of polyether-modified organosiloxane and 6kg of nano-silicon dioxide and disperse at a high speed for about 20 minutes at 3000rpm to make the nano-colloid evenly dispersed in the system. Check the fineness of the coating with a scraper fineness meter. Ensure that the fineness does not exceed 10UM;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com