Biaxially oriented polyester reflective film and manufacturing method therefor

A biaxially oriented, reflective film technology, used in reflective reflectors, chemical instruments and methods, other household appliances, etc., can solve problems such as low color contrast, inability to overcome insufficient moldability, hole deformation, etc. The effect of manufacturing deviation, excellent moldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

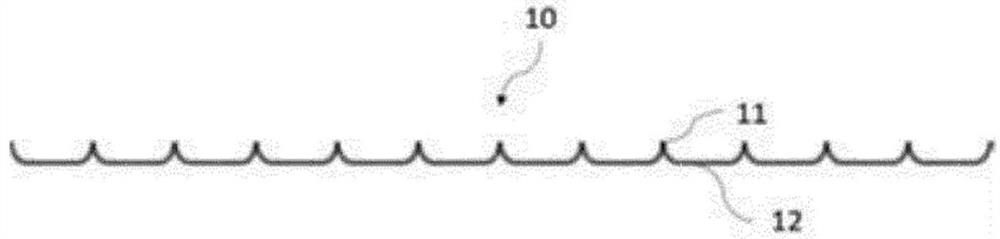

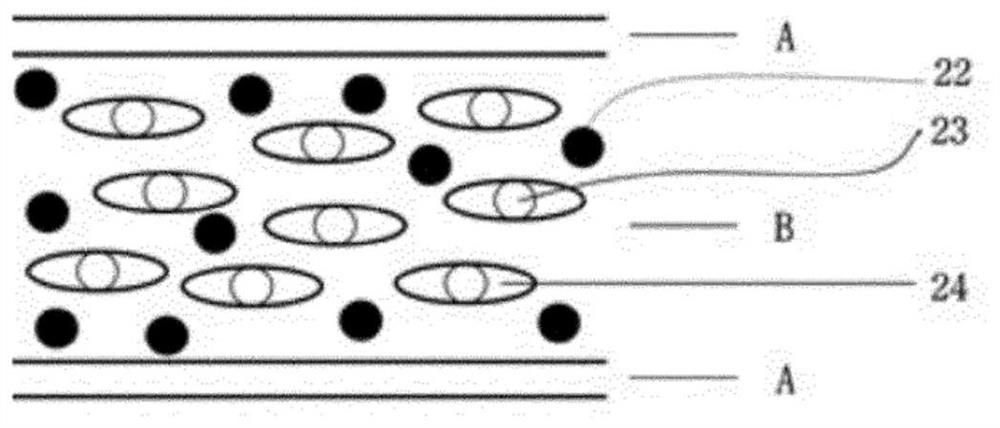

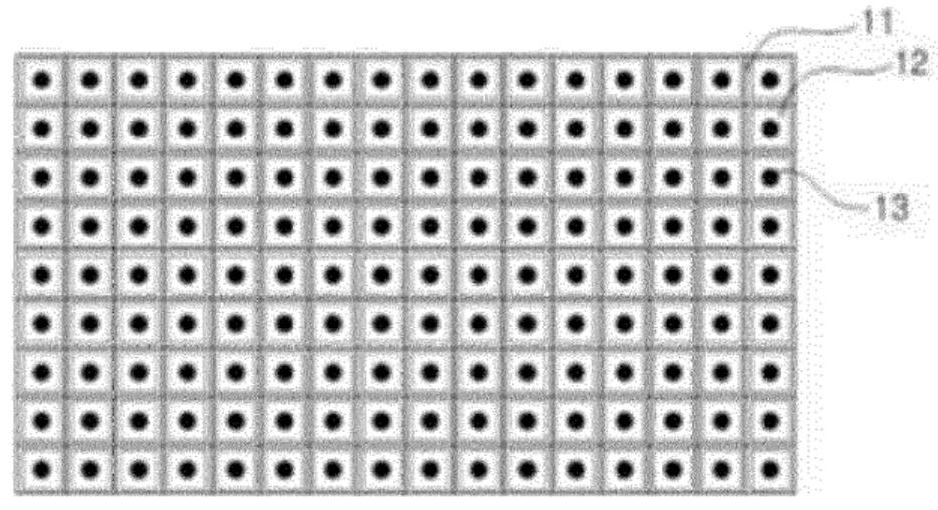

[0107] A support layer A is formed on both sides of the light reflection layer B to form a reflective film in which layers are laminated in the order of support layer A / light reflection layer B / support layer A, and based on a total thickness of 250 μm, the support layer A is opposite to The thickness ratio of the light reflection layer B was 5%. The raw materials were designed so that the support layer A had a composition of 89.9% by weight of polyethylene terephthalate (Toray Advanced Materials Korea Inc., A9093) as homopolyester, 10% by weight of copolymer polyester (Eastman Chemical Company, GN071), and 0.1% by weight of silica having an average particle diameter of 2.0 μm as inorganic particles, and such that the support layer B has a composition: 63% by weight of polyparaphenylene as homopolyester Ethylene glycol dicarboxylate (Toray Advanced Materials Korea Inc., A9093), 15% by weight of copolymer polyester (Eastman Chemical Company, GN071), 8% by weight of ethylene as r...

Embodiment 2 to Embodiment 6

[0110] A biaxially oriented polyester reflective film was prepared in the same manner as in Example 1, except that the content of the constituent materials in the light reflective layer B was changed as shown in Table 1 below, and they were used as examples 2 to 1 respectively. Each of Example 6.

experiment example

[0125] 1. Thickness measurement

[0126] The thickness of the prepared biaxially oriented polyester reflective film was measured according to JIS C2151-2006 of the Japanese Standards Association, which is a test method for plastic films for electrical applications. The biaxially oriented polyester reflective film according to the present invention was cut in the thickness direction using a microtome to obtain cross-sectional samples. Then, the thicknesses of the support layer A and the light reflection layer B were measured by a cross-sectional photograph of a cross-sectional sample magnified 250 times by a transmission electron microscope S800 manufactured by Hitachi, Ltd.

[0127] In addition, after molding the prepared biaxially oriented polyester reflective film through the molding die 200, a cross-sectional sample was obtained, and the light-collecting structure of a plurality of depressions arranged in a lattice shape was measured in the same method as above. the thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| storage modulus | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com