Material basket for supercritical fluid extraction and extraction device comprising same

A supercritical fluid and extraction device technology, applied in solid solvent extraction, solvent extraction, bulk chemical production, etc., can solve the problems of incomplete extraction, dead ends of raw material extraction, incomplete extraction, etc., to prevent the filter device from being broken or damaged. Deformation, suppressing the formation or growth of channeling, and improving extraction efficiency and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

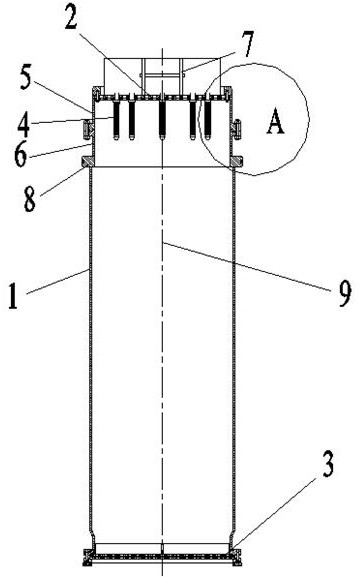

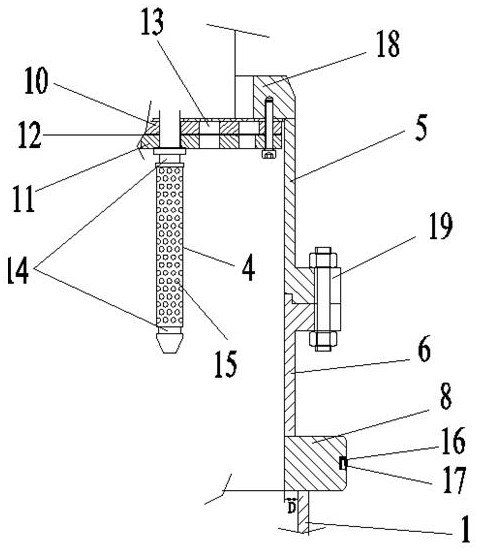

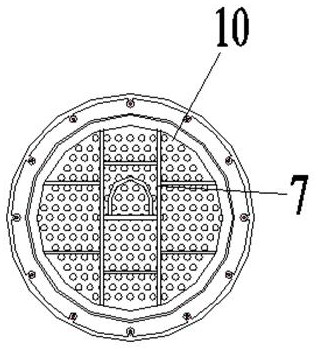

[0044] see Figure 1-3 , a material basket for supercritical fluid extraction, comprising a material basket cylinder 1, an upper filter device 2 is arranged above the material basket cylinder 1, and a lower filter device 3 is provided at the bottom thereof, the upper filter device 2 and the lower filter device 3 all include an upper orifice plate 10, a lower orifice plate 11, and a filter screen 12 sandwiched between the upper orifice plate 10 and the lower orifice plate 11, and the upper orifice plate 10 and the lower orifice plate 11 are provided with a plurality of fluid Through hole 13.

[0045] The upper filter device 2 is detachably connected with a guide device, and the guide device includes a plurality of guide tubes 4 with closed bottoms and open tops, and the bottoms of the guide tubes 4 are located under the upper filter device 2 Below the orifice plate 11, its top passes through the fluid through hole 13 of the lower orifice plate 11 of the upper filter device 2, ...

Embodiment 2

[0063] see Figure 4 The difference between this embodiment and Embodiment 1 is that the lower filter device 3 is also detachably connected with a flow guide device, and the flow guide device includes a plurality of flow guide pipes 4 with closed bottoms and open tops. The bottom of guide pipe 4 is positioned at the below of the lower orifice plate 11 of described lower filtering device 3, and its top passes through the through hole of the lower orifice plate 11 of described lower filtering device 3, filter screen 12 and upper orifice plate 10 successively. The fluid through hole 13 extends out of the upper orifice plate 10 and is detachably connected to the upper surface of the upper orifice plate 10 of the lower filter device 3 .

[0064] Described guide pipe 4 is positioned at the pipe body side wall below the lower orifice plate 11 of lower filtering device 3 and offers a plurality of guide holes 15, and guide pipe 4 is provided with the pipe outer surface of guide hole 15...

Embodiment 3

[0066] see Figure 5 , The difference between this embodiment and Embodiment 1 is that only the lower filter device 3 is provided at the bottom of the material basket cylinder 1, and the upper filter device 2, flow guide device, and material basket cover are not provided above it. 5. Protruding part 18, bracket 7, and detachably connected with guide device on this lower filtering device 3, described guide device comprises a plurality of guide tubes 4 with closed bottom and open top, described guide tube The bottom end of 4 is positioned at the below of the lower orifice plate 11 of described lower filtering device 3, and its top passes through the through hole of the lower orifice plate 11 of described lower filtering device 3, the fluid passage of filter screen 12 and upper orifice plate 10 successively. The hole 13 extends out of the upper orifice plate 10 and is detachably connected to the upper surface of the upper orifice plate 10 of the lower filtering device 3 .

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com