Integrated selective crest welder

A wave soldering machine, selective technology, applied in the direction of welding equipment, soldering iron, auxiliary devices, etc., can solve the problems of inconvenient cleaning, inconvenient disassembly and discharge of debris collection places, inconvenient debris recovery, etc., to achieve the effect of increasing cleaning, Avoid the effect of easy solidification and molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

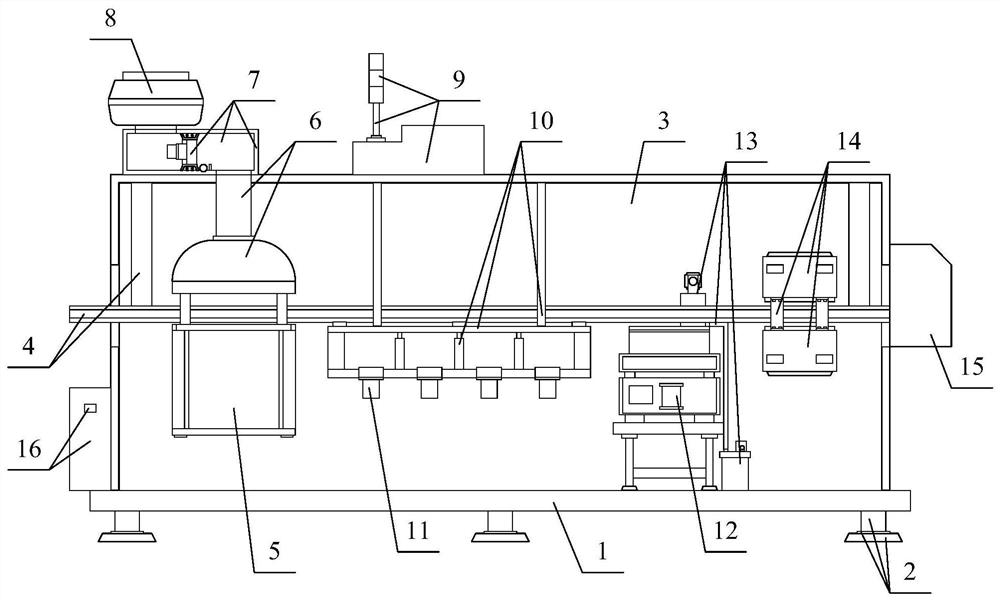

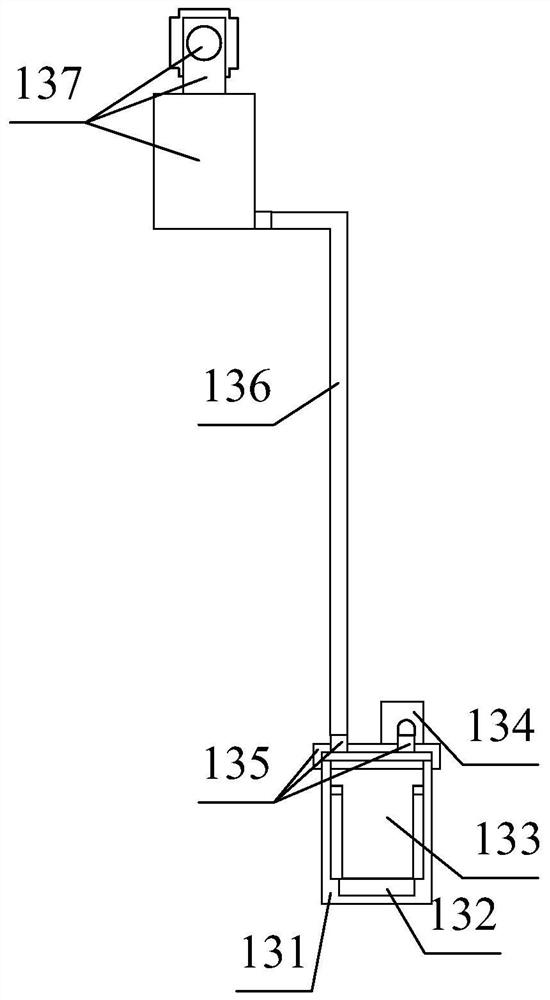

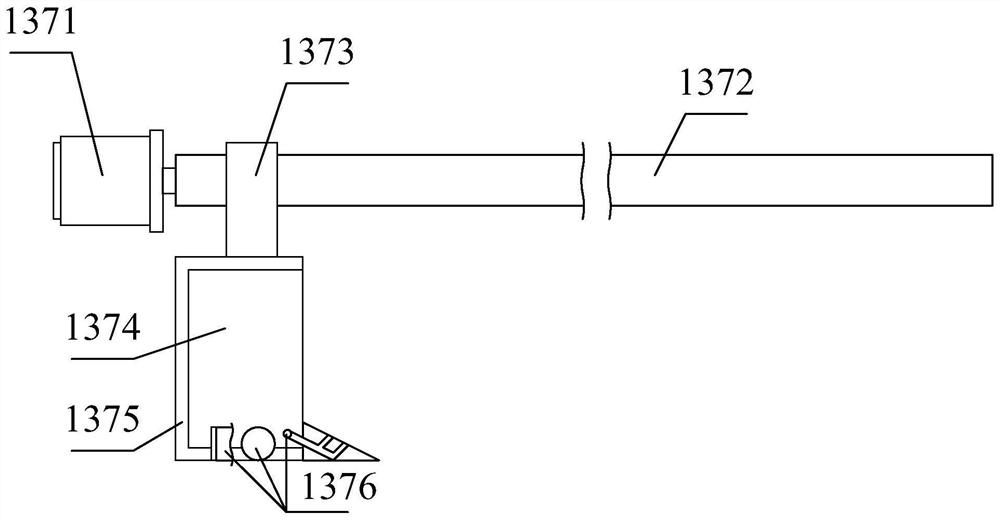

[0037] as attached figure 1As shown, the integrated selective wave soldering machine includes a supporting base plate 1, supporting feet 2, a protective disassembly shell 3, a circuit board conveying device 4, a rosin spraying device 5, a fume hood 6, a filter shaking box structure 7, and a flue gas Discharge fan 8, alarm 9, installation frame 10, preheating device 11, peak tin furnace 12, sundry cleaning collection tank structure 13, cooling device 14, claw washing device 15 and controller 16, the support base plate 1 The outer bolts at the upper end are equipped with a protective disassembly shell 3; the support feet 2 are respectively bolted on the surroundings of the lower end of the support base plate 1 and the front and rear sides of the middle part; the circuit board conveying device 4 bolts are installed on the protection disassembly The left and right sides of the upper part of the inner wall of the shell 3; the bolts of the rosin spray device 5 are installed on the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com