Silver thin film etching liquid composition, etching method using same, and metal pattern forming method

An etching solution and composition technology, applied in the field of silver thin film etching solution composition, can solve the problems of silver re-adsorption, wiring bite, performance degradation, etc., and achieve the effects of reducing side etching amount, maintaining etching performance, and improving etching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

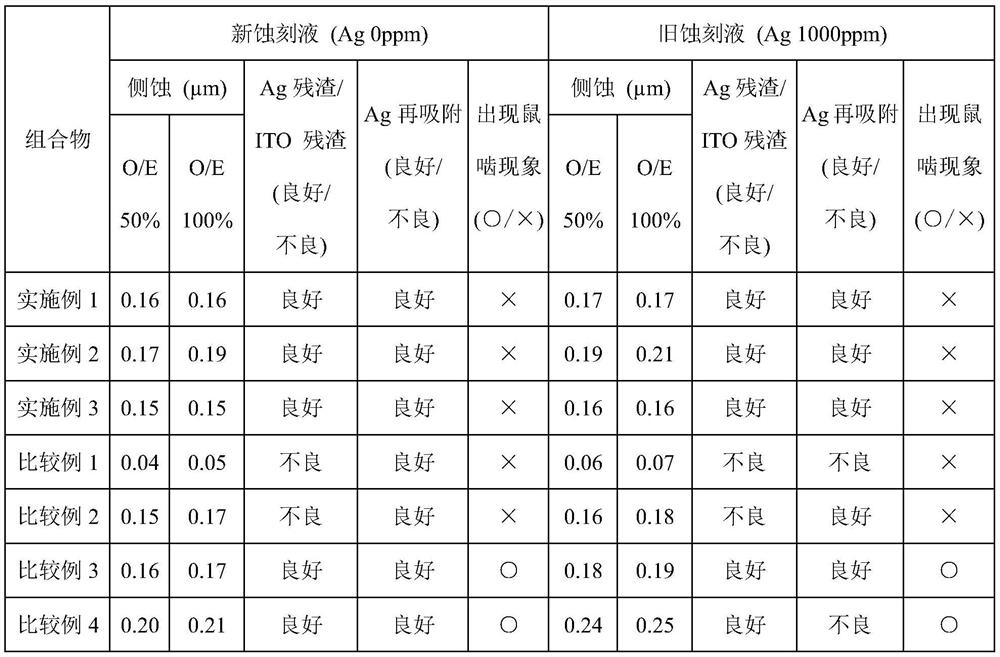

[0087] 1. New etchant and old etchant

[0088] The state just prepared of the silver thin film etchant compositions of Examples 1 to 3 and Comparative Examples 1 to 4 is called a new etchant, and the etchant has been subjected to a long-time etching process in order to assume that the etching solutions of Examples and Comparative Examples And the state after artificially dissolving 1000ppm silver powder (assessment of processing quantity) is called old etching solution.

[0089] Etching characteristics were evaluated by the following methods 2 to 5 using the new etchant and the old etchant, respectively.

[0090] 2. Side erosion measurement

[0091] After forming the ITO / silver / ITO trilayer film on the substrate, photoresist patterning was carried out on the trilayer film.

[0092] The silver thin film etchant composition of embodiment 1 to 3 and comparative example 1 to 4 is put into the experimental equipment (model: ETCHER (TFT), SEMES company) of spray type etching metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com