Flexible sensing array for manipulator sensing and preparation and application method thereof

A sensor array and sensor array technology, applied in the field of flexible sensors, to achieve the effects of improving sensitivity, good repeatability and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The preparation method of flexible sensor array comprises the following steps:

[0051] Step 1: Mix one-dimensional conductive nanomaterials and two-dimensional conductive nanomaterials (such as CNT and Mxene) in a certain ratio (0.5-2:1), configure composite conductive nanomaterials, and add them to a beaker. Then add SEBS powder, the mass ratio of SEBS and composite conductive nanomaterials is 1:0.2-0.5, and stir evenly with a glass rod.

[0052] Step 2: Add absolute ethanol to the beaker so that the absolute ethanol can cover the material. Put the beaker into an ultrasonic machine and heat it in a blast drying oven until the ethanol is completely evaporated. The dried material is ground to obtain a uniformly mixed composite nano material.

[0053] Step 3: Add paraffin oil to the material (the mass ratio of paraffin oil and SEBS is 2.5-3.5:1), and stir evenly with a glass rod. Put the mixed material into a crucible and lay it flat, then put it into a box furnace, h...

example 1

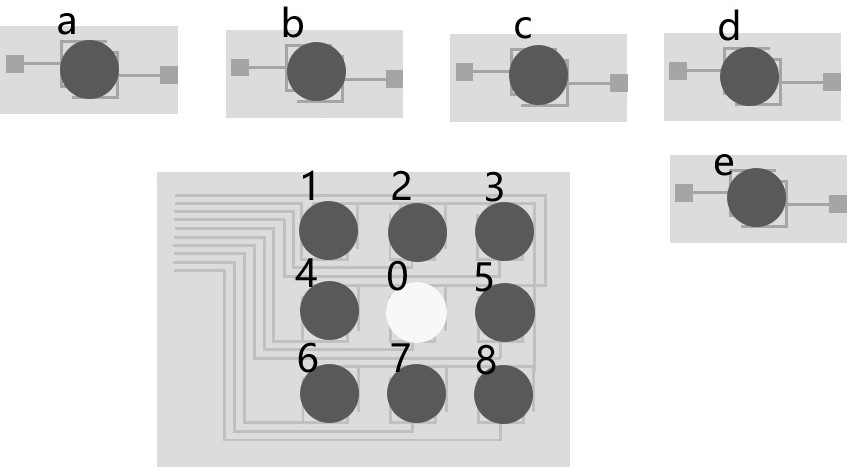

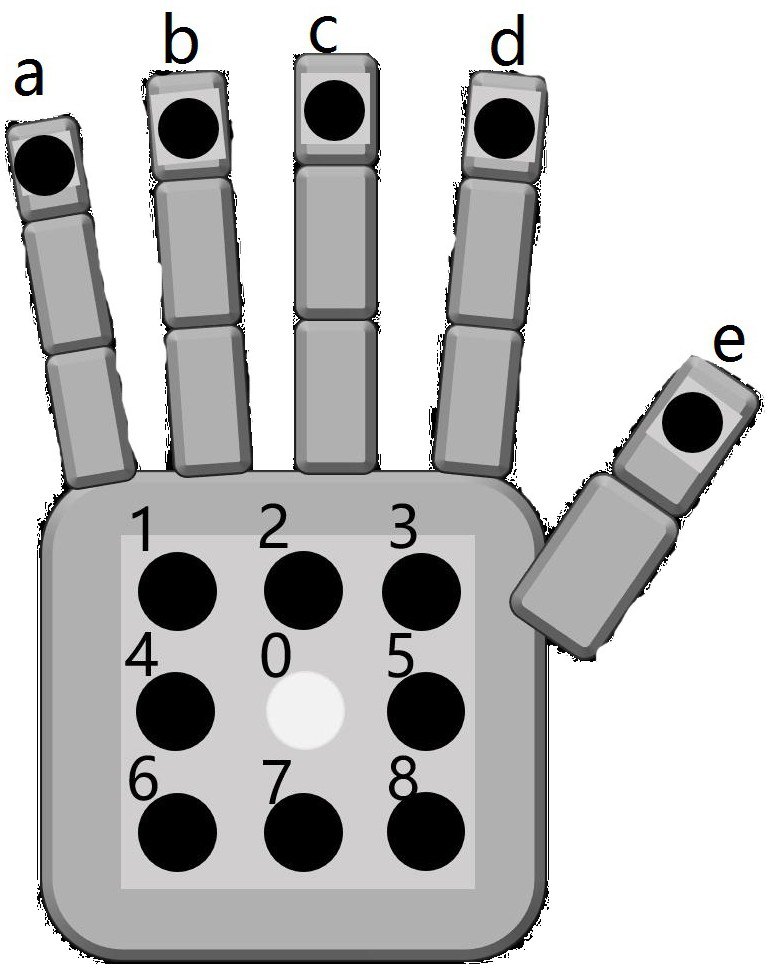

[0068] A flexible proximity and pressure sensing array based on composite nanomaterials for bionic manipulator sensing, including: film substrates, electrodes, flexible piezoresistive sensing units, and flexible capacitive sensing units.

[0069] The film substrate is a 100 μm PET film.

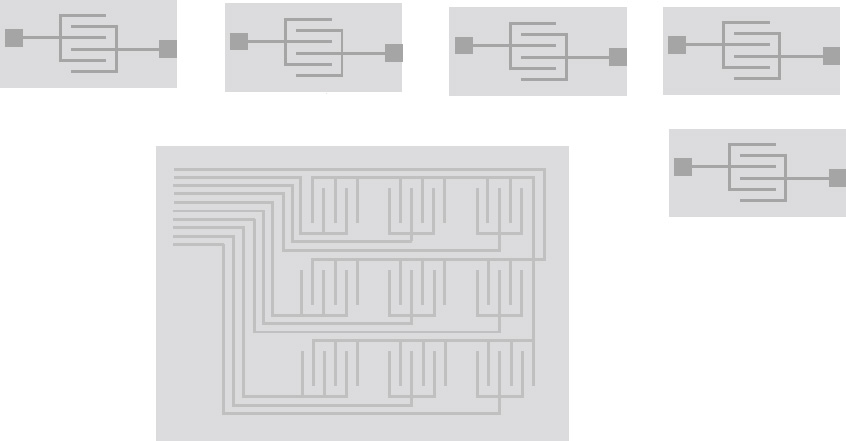

[0070] The electrode 2 is a 3ⅹ3 interdigitated electrode array, and the material can be silver, copper and other nano-materials, printed on the film substrate.

[0071] The flexible piezoresistive sensing unit is composed of multiple piezoresistive sensing patches of the same size from the same sensing material. The sensing patch is made of composite nanomaterials as the sensitive material, in the shape of a cube or cylinder, etc., with a thickness of 3 -3.5mm.

[0072] The flexible capacitive sensing unit is a capacitive sensing patch made of SEBS and paraffin, and its shape and size are consistent with the piezoresistive sensing unit.

[0073] The sensor patches are attached to the electr...

example 2

[0089] A flexible proximity and pressure sensing array based on composite nanomaterials for three-finger manipulator sensing, including: a film substrate, electrodes, a flexible piezoresistive sensing unit, and a flexible capacitive sensing unit.

[0090] The film substrate is a 50 μm PET film.

[0091] The electrode is an array of interdigitated electrodes, and the material can be nano-materials such as silver and copper, which are printed on the film substrate.

[0092] The piezoresistive sensing unit is composed of multiple piezoresistive sensing patches from the same sensing material and of the same size. The sensing patch is made of CNT as the sensitive material, in the shape of a cube or cylinder, etc., with a thickness of 3-3.5mm .

[0093] The capacitive sensing unit is a capacitive sensing patch, made of SEBS and paraffin, with the same shape and size as the piezoresistive sensing unit.

[0094] The sensor patches are attached to the electrodes one by one to form a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com