Flue gas purification system capable of comprehensively utilizing heat and process thereof

A flue gas purification system and heat technology, applied in preheating, gas treatment, liquid degassing, etc., can solve the problems of low utilization rate of heat, complex system settings, etc., and achieve the effect of improving the comprehensive utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

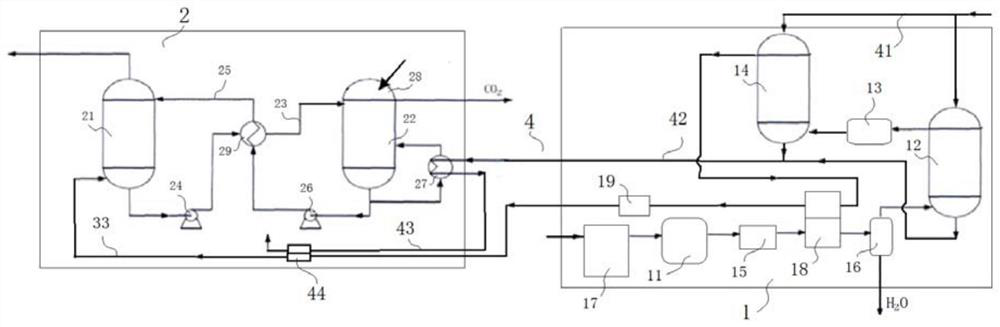

[0052] A flue gas purification system for comprehensive utilization of heat, including COAP system 1, CO 2 Chemical absorption system 2, steam heat utilization pipeline system 4, this setting can effectively utilize the high-temperature steam discharged from the steam turbine of the power plant for reasonable application step by step, such as figure 1 As shown, the simplification of the equipment improves the utilization of heat. Among them, the COAP system 1 is used to discharge the flue gas after desulfurization and denitration; CO 2 The chemical absorption system 2 is used to remove carbon in the flue gas discharged from the COAP system 1; the steam heat utilization pipeline system 4 is used to realize the rational application of high temperature steam step by step.

[0053] In this example, the CO 2 The chemical absorption system 2 includes an absorption tower 21 , a regeneration tower 22 , a rich liquid pipe 23 , a rich liquid pump 24 , a lean liquid pipe 25 , a lean li...

Embodiment 2

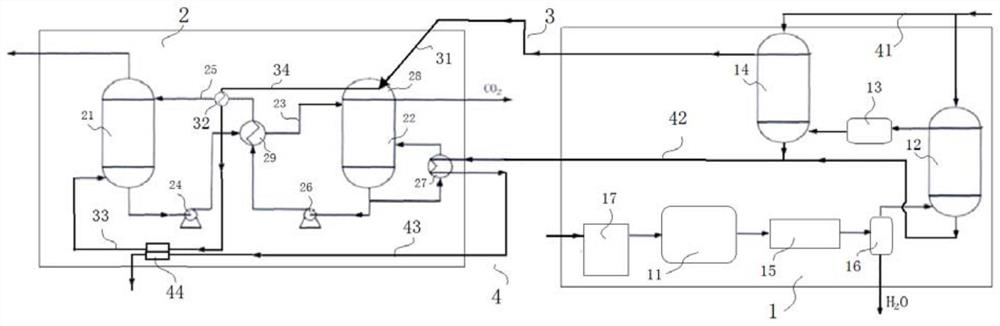

[0058] A flue gas purification system for comprehensive utilization of heat, including COAP system 1, CO 2 Chemical absorption system 2, steam heat utilization pipeline system 4 and cooling capacity utilization pipeline system 3, this setting can effectively apply the cooling capacity in the low-temperature flue gas discharged from COAP system 1 step by step reasonably, such as figure 2 shown. Among them, the COAP system 1 is used to discharge the flue gas after desulfurization and denitration; CO 2 The chemical absorption system 2 is used to remove carbon from the flue gas discharged from the COAP system 1; the steam heat utilization pipeline system 4 is used to realize the rational application of high temperature steam step by step; the cooling capacity utilization pipeline system 3 is used to realize the COAP system 1 The rational application of the cooling capacity in the exhausted low-temperature flue gas step by step.

[0059] In this example, the CO 2 The chemical a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com