Cutting device and sealing system

A cutting device and sealing box technology, applied in feeding devices, maintenance and safety accessories, manufacturing tools, etc., can solve the problems of internal pollution of the sealing box, complicated maintenance process, inconvenient replacement, etc., and achieve high operating stability, Easy disassembly and replacement, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

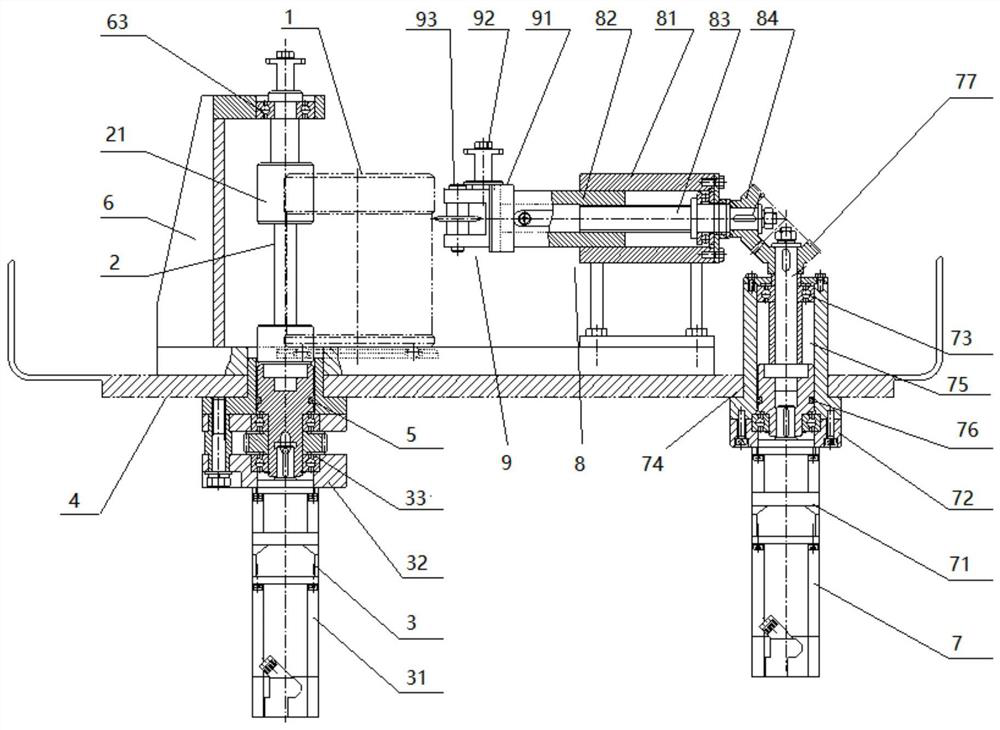

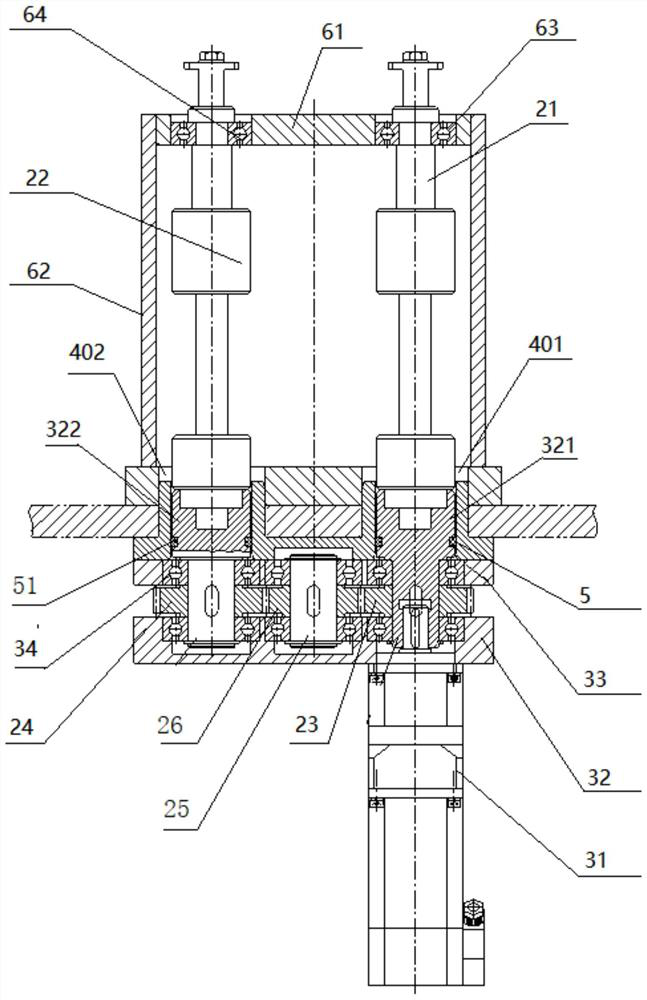

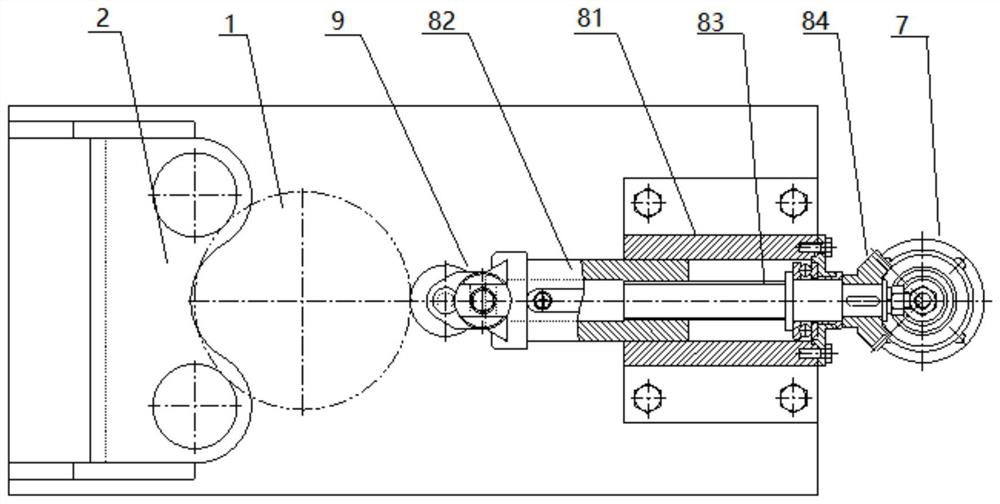

[0030] Such as figure 1 As shown, this embodiment discloses a cutting device, including a rotating mechanism, a feeding mechanism, and a cutting mechanism 9. The rotating mechanism includes a transmission support assembly and a rotary drive assembly 3. The rotary drive assembly 3 is arranged outside the sealed box 4 for Drive the transmission support assembly to rotate, the transmission support assembly is arranged in the sealed box 4, and is used to support the object 1 to be cut and drive the object 1 to be cut to rotate under the drive of the rotary drive assembly 3, and the cutting mechanism 9 is arranged in the sealed box 4 , for cutting the cut object 1, the feeding mechanism includes a feeding assembly 8 and a feeding drive assembly 7, the feeding assembly 8 is arranged in the sealed box 4, and is connected with the cutting mechanism 9, and is used to drive the cutting mechanism 9 moves toward the object to be cut 1, and the feed drive assembly 7 is arranged outside the...

Embodiment 2

[0044] This embodiment discloses a sealing system, which includes a sealing box 4, and a material cup is arranged inside the sealing box 4. The sealing system also includes the cutting device in Embodiment 1, and the cutting device is used to cut the material cup.

[0045] In this embodiment, the sealed box 4 has a good sealing performance, effectively blocking radiation-containing pollutants in the sealed box 4, and the cutting device can efficiently and stably complete the cutting of the material cup.

[0046] The working process of the sealing system is as follows:

[0047] Place the cup on the first rotating shaft 21 and the second rotating shaft 22 inside the sealed box 4, turn on the first motor 31, and the first rotating shaft 21 and the second rotating shaft 22 rotate under the drive of the first motor 31 Thereby driving the material cup to rotate at a high speed.

[0048] Then, turn on the second motor 71, so that the first bevel gear 77 drives the second bevel gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com