High-density polyethylene product processing cutting device

A high-density polyethylene and cutting device technology, which is applied in metal processing, grinding drive devices, metal processing equipment, etc., can solve the problems of low production efficiency, inconvenient adjustment of polyethylene pipe grinding and cutting positions, and occupied area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

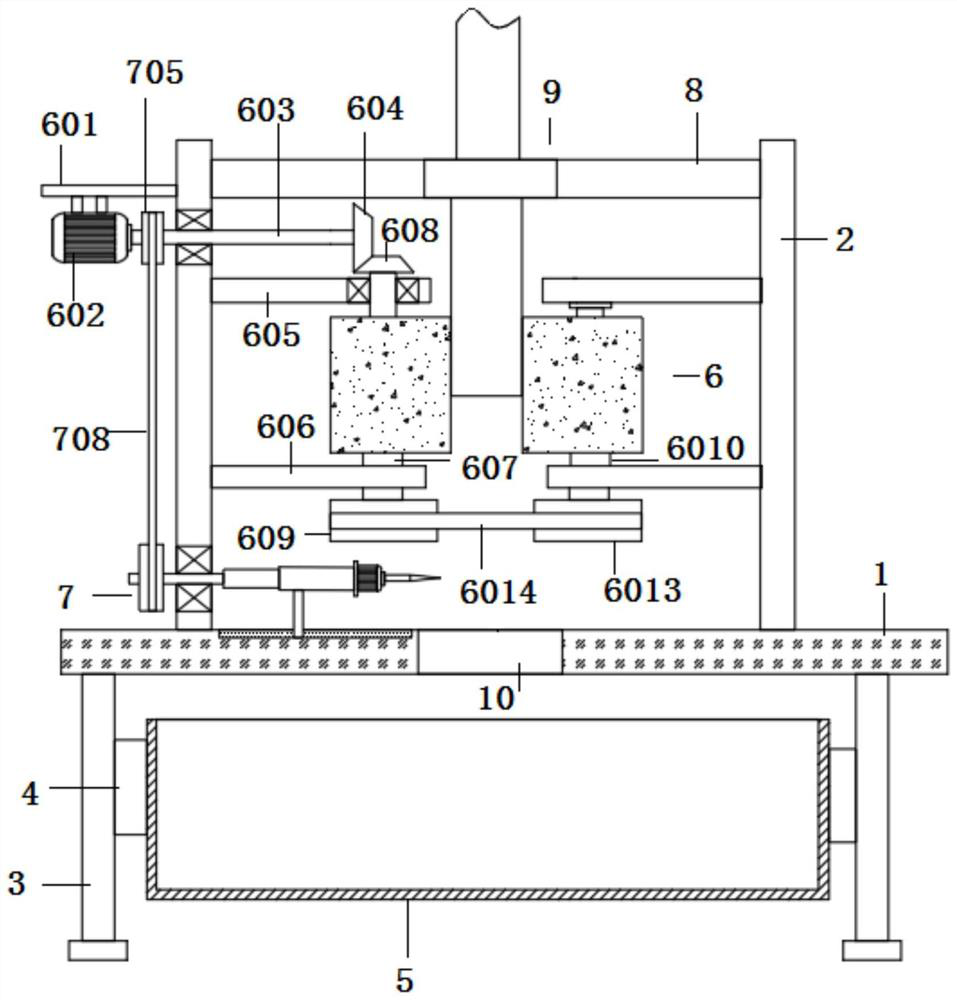

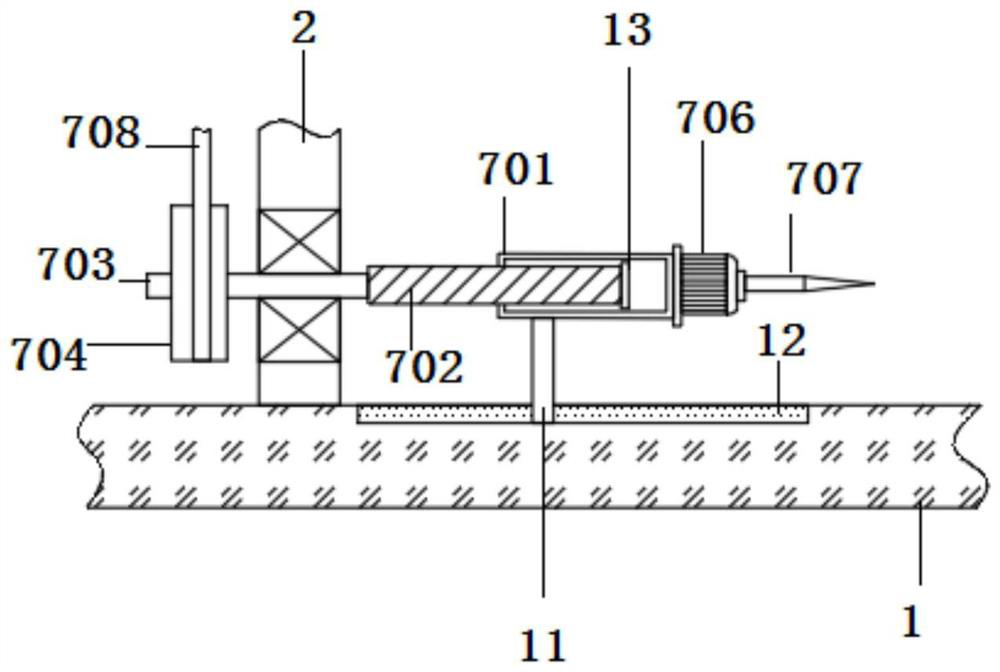

[0033] like Figure 1-5 As shown, the present invention is a cutting device for high-density polyethylene product processing, including a cutting table 1, the top of the cutting table 1 is symmetrically fixed with connecting braces 2 on both sides, and the bottom is symmetrically fixed on both sides of the support column 3, A polyethylene recovery box 5 is connected between the two sets of support columns 3 through a detachable mechanism 4, and a grinding mechanism 6 and a cutting mechanism 7 are respectively provided between the two sets of connecting braces 2 from top to bottom, and the two sets of connecting braces 2 are located at An installation top plate 8 is fixed between the grinding mechanism 6 and the cutting mechanism 7 , and the installation top plate 8 is provided with a limit fastening mechanism 9 .

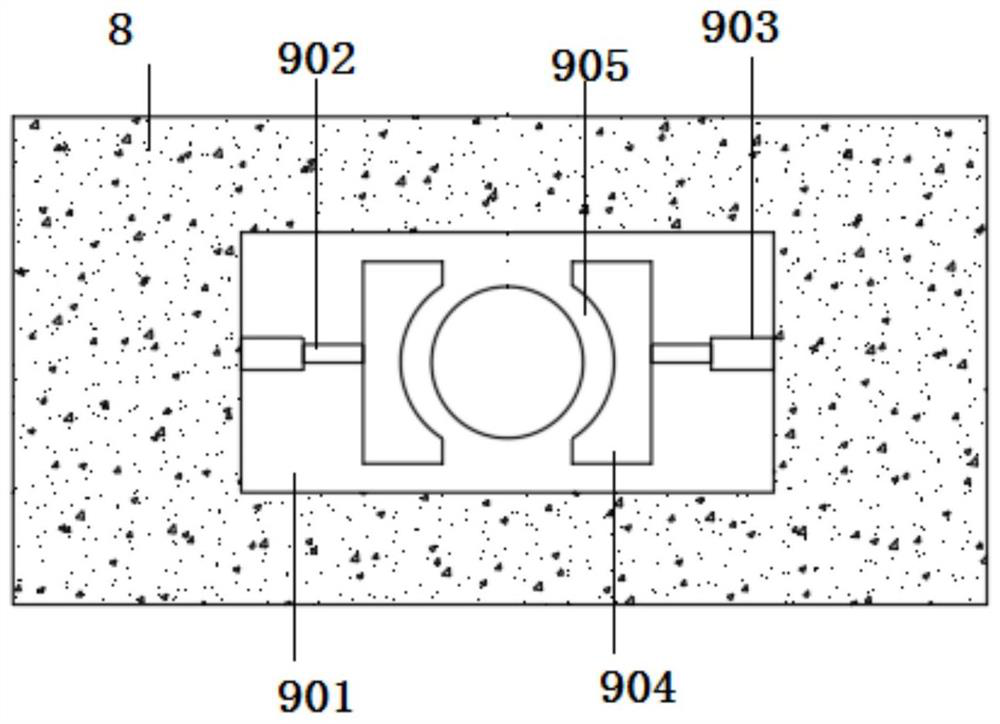

[0034] Wherein, the position-limiting fastening mechanism 9 includes a fastening slot 901. The fastening slot 901 runs through the middle of the installation top pl...

Embodiment 2

[0037] A cutting device for processing high-density polyethylene products, comprising a cutting table 1, a connecting support plate 2 is symmetrically fixed on both sides of the top of the cutting table 1, and supporting columns 3 are symmetrically fixed on both sides of the bottom of the cutting processing table 1, and the two sets of supporting columns 3 A polyethylene recovery box 5 is connected between them through a detachable mechanism 4, and a grinding mechanism 6 and a cutting mechanism 7 are respectively provided between the two sets of connecting stays 2 from top to bottom, and the two sets of connecting stays 2 are located between the grinding mechanism 6 and the cutting mechanism. 7 is fixed with an installation top plate 8, and the installation top plate 8 is provided with a limit fastening mechanism 9;

[0038] Wherein, the limit fastening mechanism 9 includes a fastening slot 901, which runs through the middle of the installation top plate 8, and the inner side w...

Embodiment 3

[0042] A cutting device for processing high-density polyethylene products, comprising a cutting table 1, a connecting support plate 2 is symmetrically fixed on both sides of the top of the cutting table 1, and supporting columns 3 are symmetrically fixed on both sides of the bottom of the cutting processing table 1, and the two sets of supporting columns 3 A polyethylene recovery box 5 is connected between them through a detachable mechanism 4, and a grinding mechanism 6 and a cutting mechanism 7 are respectively provided between the two sets of connecting stays 2 from top to bottom, and the two sets of connecting stays 2 are located between the grinding mechanism 6 and the cutting mechanism. 7 is fixed with an installation top plate 8, and the installation top plate 8 is provided with a limit fastening mechanism 9;

[0043] Wherein, the limit fastening mechanism 9 includes a fastening slot 901, which runs through the middle of the installation top plate 8, and the inner side w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com