A kind of wear-resistant TBM knife ring and its preparation method and application

A technology of knife ring and induction furnace is applied in the field of metal materials to achieve the effects of simple process, improved wear resistance and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

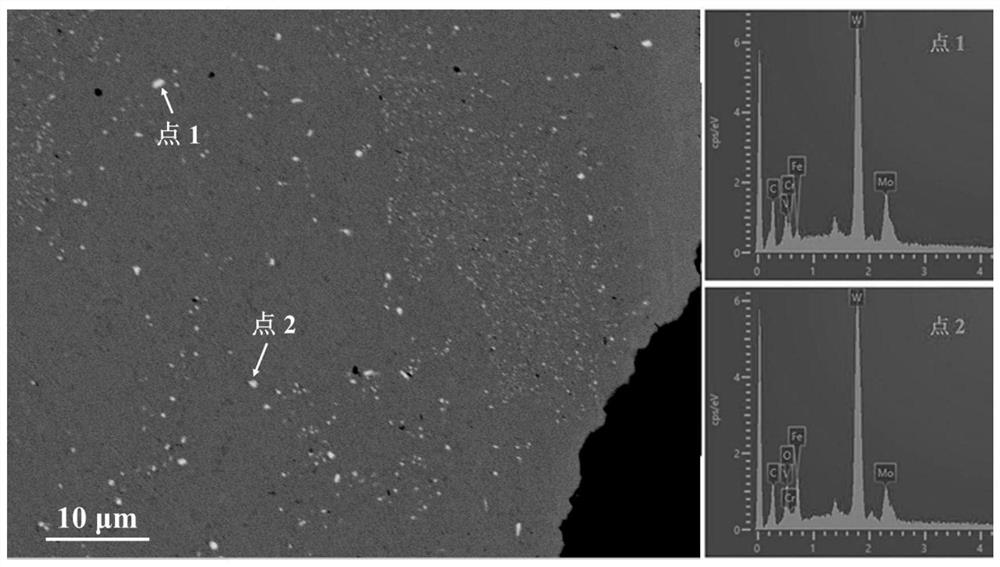

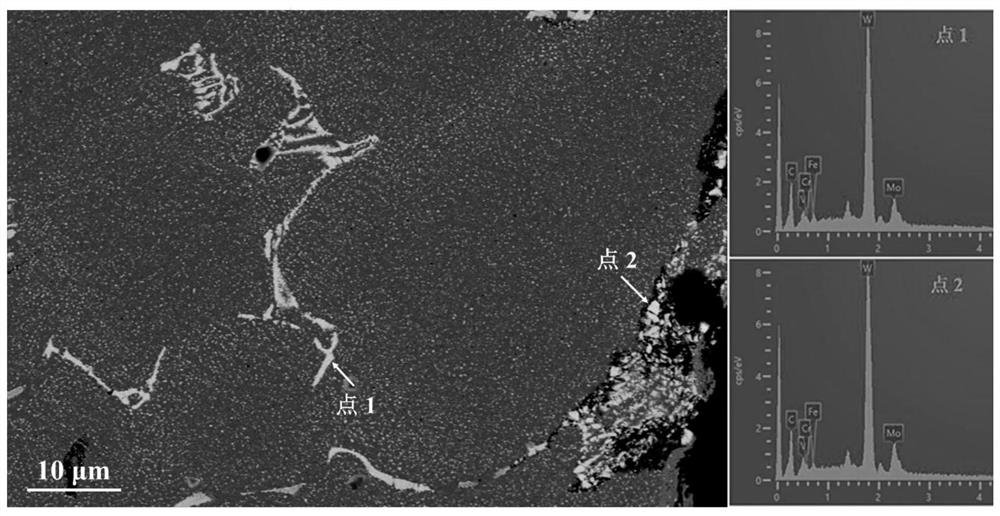

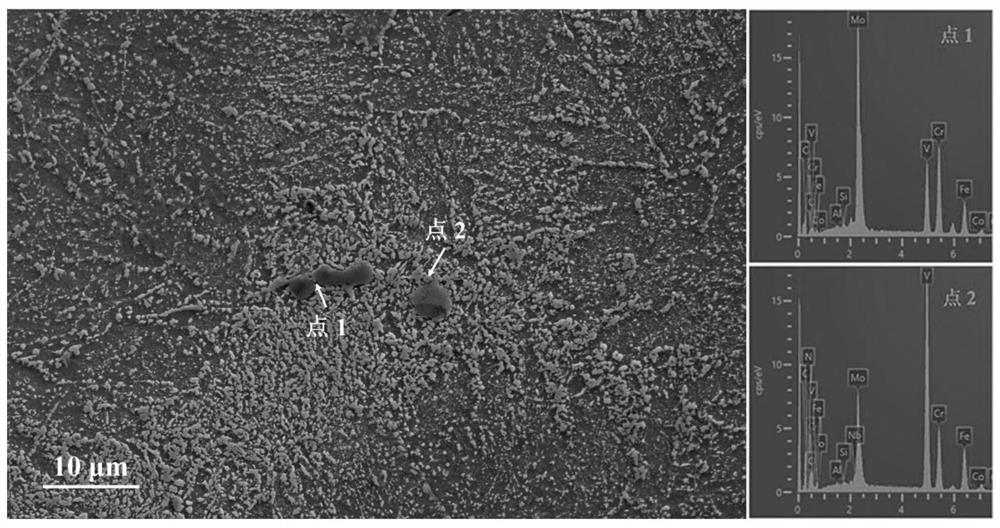

Image

Examples

Embodiment 1

[0035] This embodiment provides a wear-resistant TBM cutter ring. The chemical composition of the molten steel is calculated by mass percentage, including: C0.45%, Si 1.2%, Mn 0.45%, Cr 5.2%, Mo 1.1%, V 0.8%, Al 0.02%, W0.04%, Fe90.74%.

[0036] A preparation method of a wear-resistant TBM cutter ring, comprising the following steps:

[0037] Step 1, provide raw materials;

[0038] In step 2, the raw materials are placed in an intermediate frequency induction furnace for smelting, and the whole process is protected by argon gas. During the smelting process, the upper part of the molten steel is covered with a layer of smelting slag, and the smelting temperature is controlled at 1600℃; after the smelting is completed, the tapping temperature of the intermediate frequency induction furnace is controlled at 1590℃ and the oxygen content is 20ppm;

[0039] Step 3, start the vertical centrifuge with the casting mold before tapping the intermediate frequency induction furnace, and ...

Embodiment 2

[0042] This embodiment provides a wear-resistant TBM cutter ring, the chemical composition of which is calculated by mass percentage, including: C 0.55%, Si 0.8%, Mn 0.25%, Cr 4.4%, Mo 1.5%, V 1.2%, Al 0.03%, W 0.02%, Fe 91.25%.

[0043] A preparation method of a wear-resistant TBM cutter ring, comprising the following steps:

[0044] Step 1, provide raw materials;

[0045] In step 2, the raw materials are placed in an intermediate frequency induction furnace for smelting, and the whole process is protected by argon gas. During the smelting process, the upper part of the molten steel is covered with a layer of smelting slag, and the smelting temperature is controlled at 1750°C; after the smelting is completed, the tapping temperature of the intermediate frequency induction furnace is controlled at 1660°C and the oxygen content is 30ppm;

[0046] Step 3, start the vertical centrifuge with the casting mold before tapping the intermediate frequency induction furnace, and pour t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com