Ultra-large self-elevating gravel laying and leveling ship

A self-elevating, ultra-large technology, applied in the direction of construction, infrastructure engineering, etc., can solve the problems such as the limited service life of the pile leg fatigue life lifting system, the large longitudinal span of the hull structure, and the impact on the accuracy of gravel leveling, etc., to achieve It is beneficial to the layout, optimizes the size of the hull, and optimizes the effect of the leg length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

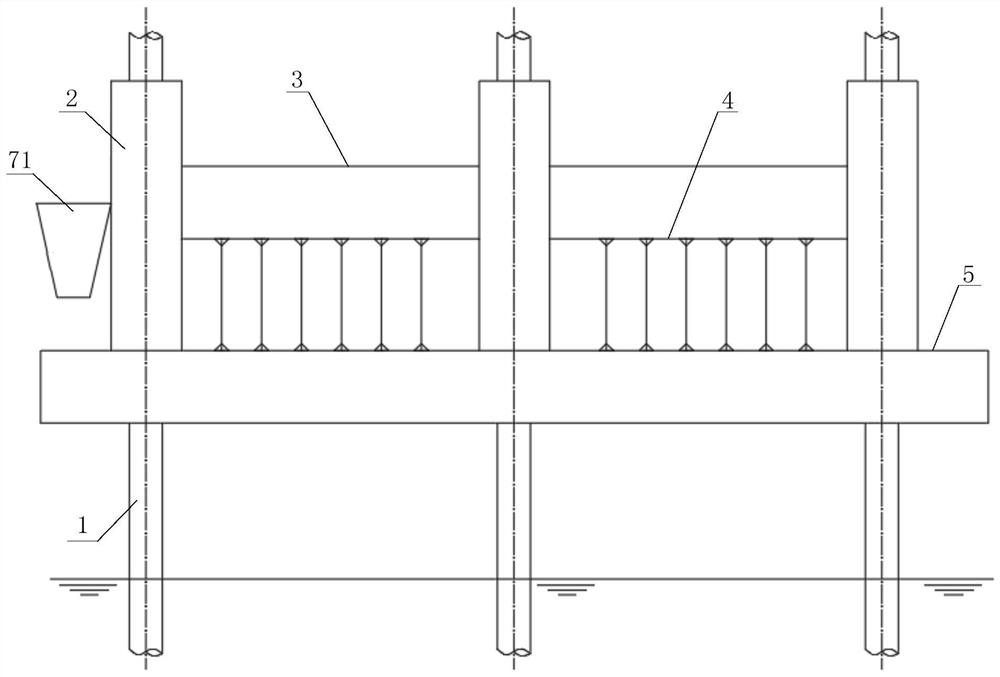

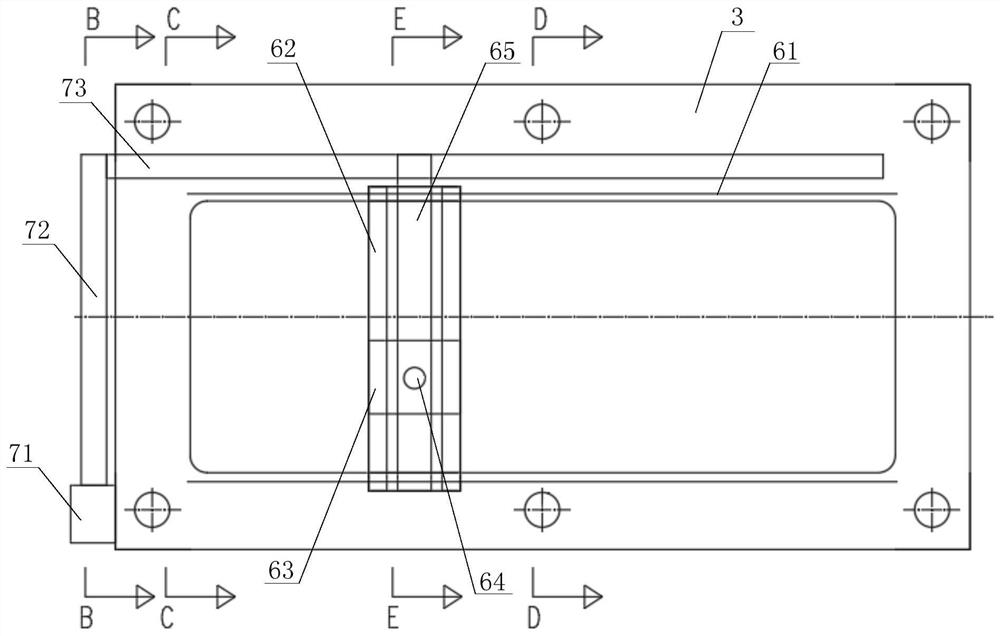

[0043] Below according to the accompanying drawings Figure 1 to Figure 9 , give a preferred embodiment of the present invention, and give a detailed description, so that the functions and characteristics of the present invention can be better understood.

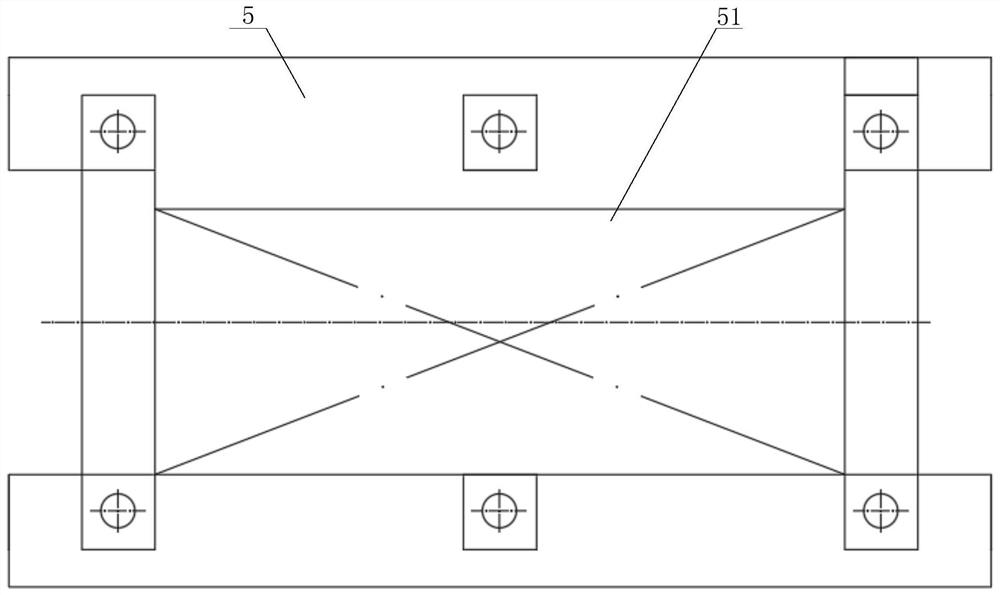

[0044] see Figure 1 to Figure 9 , a super-large self-elevating gravel laying screed ship according to an embodiment of the present invention, comprising a hull, six legs 1, a gravel transmission mechanism and a riprap mechanism; the legs 1 pass through a lifting tower mechanism 2 respectively Connected to both sides of the two ends of the hull and the sides of the middle; the hull includes a top deck 3, a middle deck 4 and a main deck 5 which are stacked in sequence; the main deck 5 forms a moon pool 51; the top deck 3 and the middle deck 4 Hollow out at the place corresponding to the moon pool 51; the rock-throwing mechanism is arranged on the top deck 3; the gravel conveying mechanism is arranged on the hull and extends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com