Fabricated rubble slope surface protection structure and construction method

A technology of protective structure and construction method, applied in basic structure engineering, excavation, protection device and other directions, can solve the problems of low construction efficiency, large amount of engineering, long construction period, etc., to reduce excavation slag, speed up construction, reduce cracking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

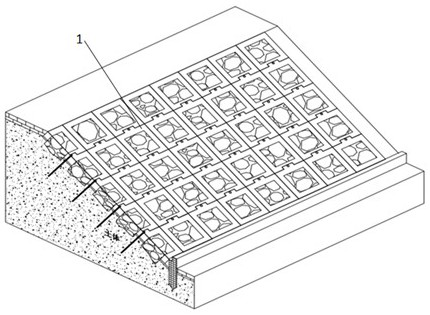

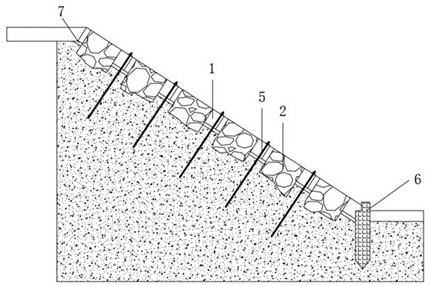

[0054] Such as Figure 1~10 As shown, a prefabricated rubble slope slope protection structure includes a slope soil body, an assembled masonry skeleton 1 is fixed on the slope surface of the slope soil body, and the masonry skeleton 1 extends from the slope surface to the slope surface. The feet are occluded and fixed by the assembled structure. The masonry skeleton 1 is paved with masonry rubble 2 . Bottom support for the masonry frame 1.

[0055] The masonry skeleton 1 includes a masonry skeleton on a slope top and a masonry skeleton on a slope surface, and the masonry skeleton on a slope top is located at the top of a slope soil.

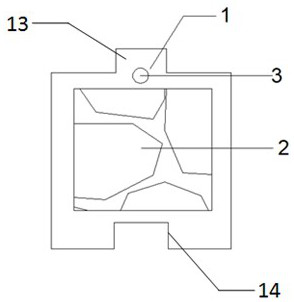

[0056] The masonry skeleton of the slope roof includes a top rectangular frame body, the accommodating cavity of the top rectangular frame body accommodates the grouted rubble 2 , and a groove 14 for assembling is formed on one si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com