Iron tower assembling and hoisting auxiliary assembly

A technology of iron tower assembly and auxiliary components, which is applied in the direction of towers, building types, buildings, etc., can solve the problems of system safety performance degradation, small hoisting radius, and inability to ensure synchronization, so as to improve assembly efficiency and safety, and ensure assembly Efficiency, the effect of increasing applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

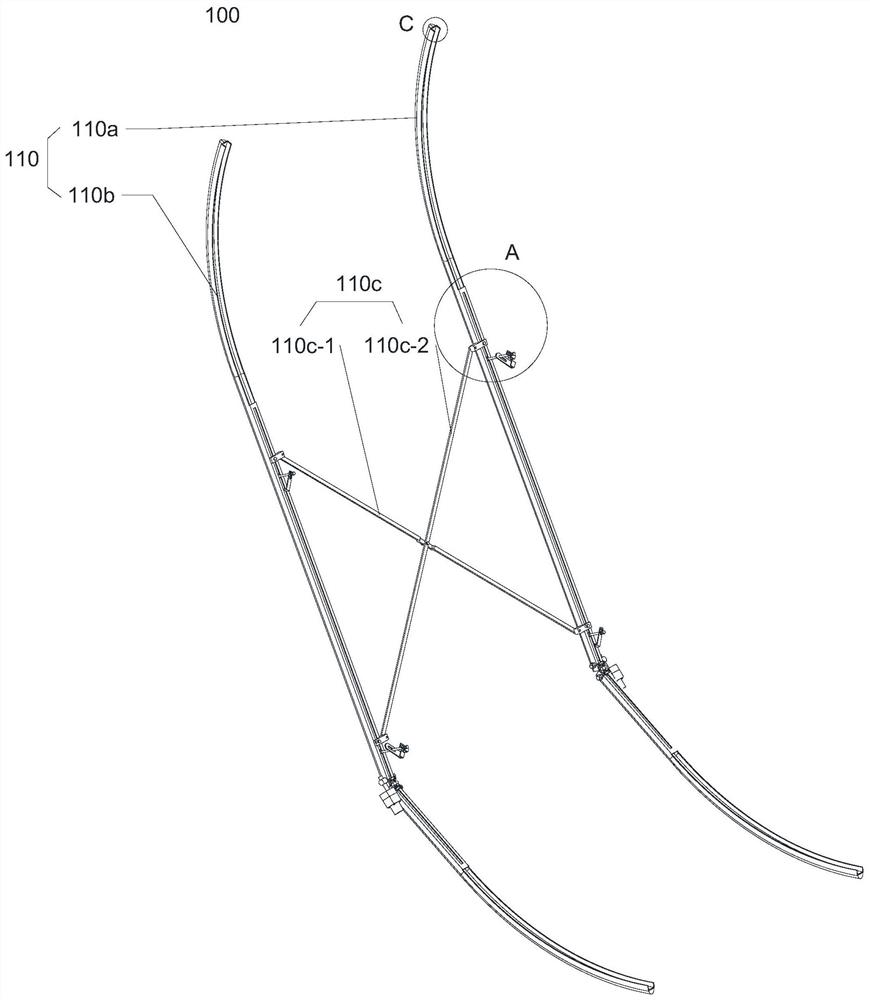

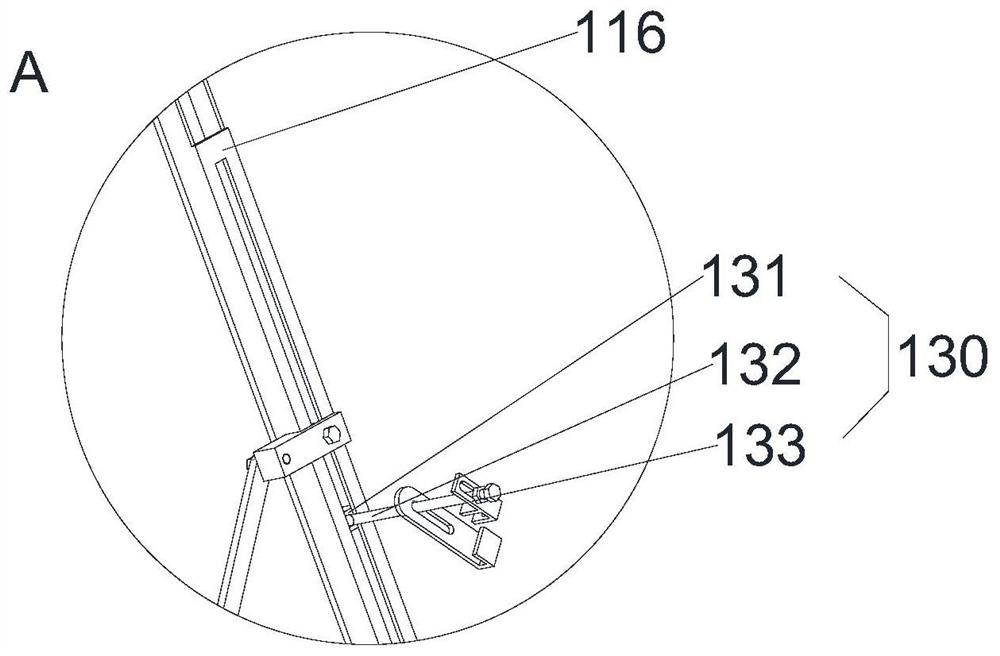

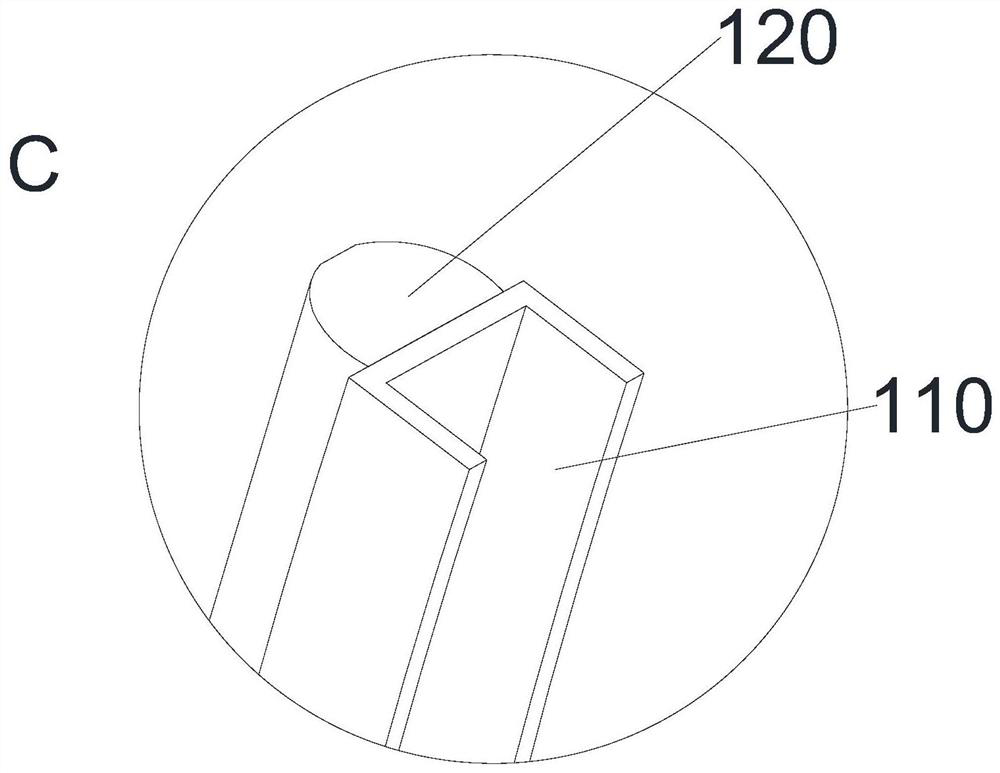

[0042] Such as Figure 1-Figure 3 As shown, the embodiment of the present invention provides an auxiliary assembly for iron tower erection and hoisting, including: a sling 100, the sling 100 includes a sling body 110, a polytetrafluoroethylene layer 120 and a fixing assembly 130; The vinyl fluoride layer 120 is arranged on one side of the sling body 110; the fixing component 130 is arranged on the other side opposite to the sling body 110; The polytetrafluoroethylene layer 120 cooperates with the assembled tower section and assists the spreader 100 to move along the surface of the assembled tower section.

[0043] Specifically, the spreader body 110 includes but is not limited to a flat plate, a strip structure, etc. The present invention uses the high temperature resistance of the polytetrafluoroethylene to contact the surface of the assembled tower section by setting the polytetrafluoroethylene layer 120 And the characteristics of low friction coefficient, so as to realize ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com