Compression and expansion co-body machine for supercritical carbon dioxide Brayton system

A technology of carbon dioxide and compression expansion, which is applied in the direction of mechanical equipment, machines/engines, non-variable pumps, etc., can solve the problems of high cost, achieve the effects of reducing requirements, avoiding drive energy conversion, and improving rotor dynamics characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

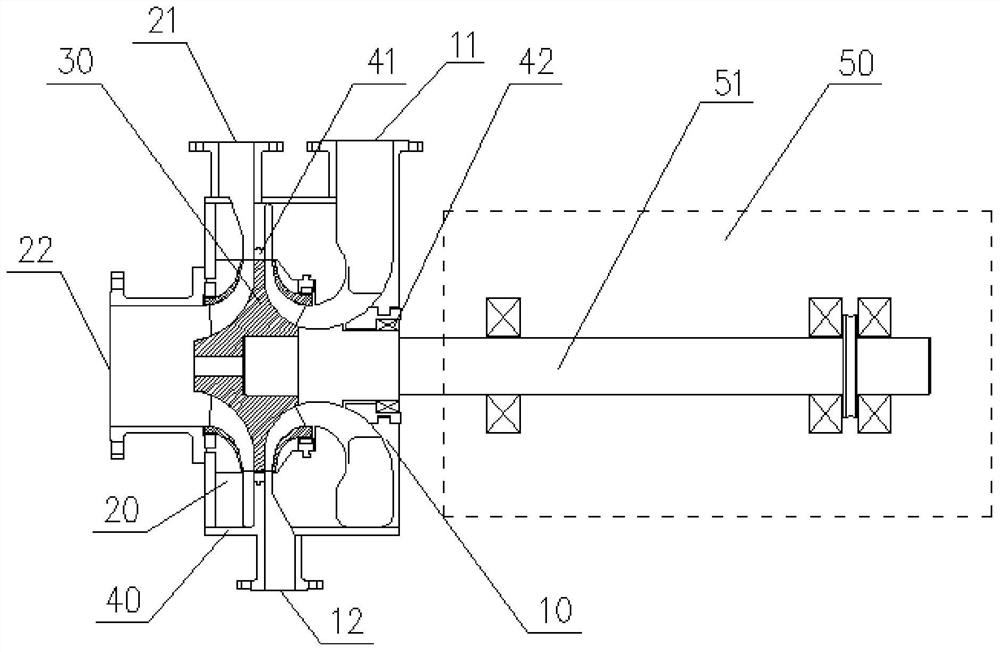

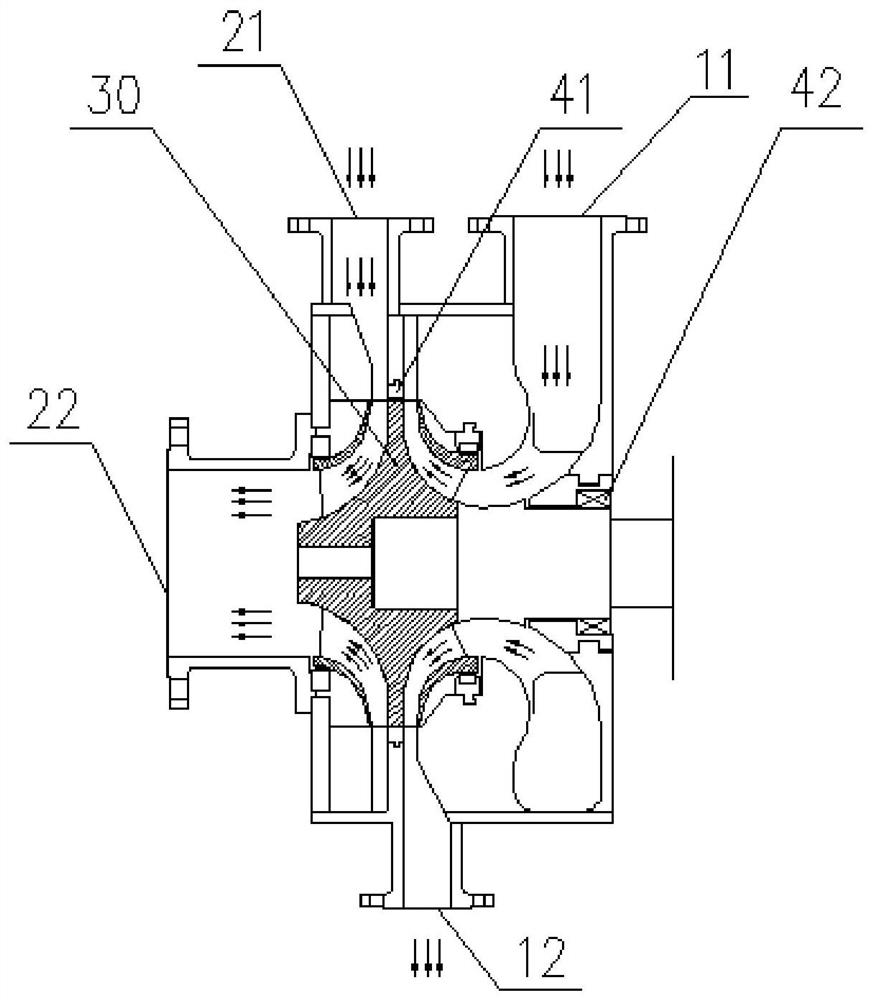

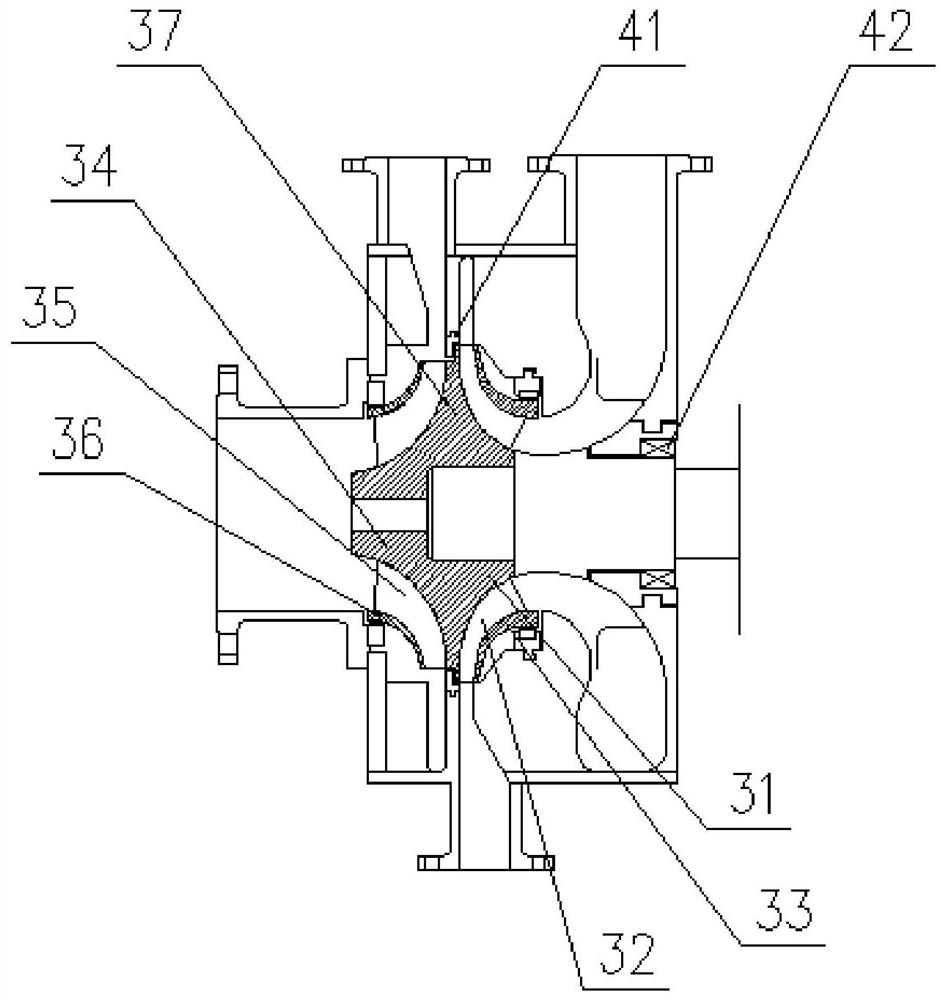

[0029] Embodiment 1: as Figure 1-3 As shown, the disk includes a compressor disk 31, an expander disk 34, and a middle disk 37, and the compressor disk 31 and the expander disk 34 are respectively located on both sides of the middle disk 37. The disk is an integral part, or at least one of the compressor disk 31 and the expander disk 34 is welded to the middle disk 37, and the mechanical gap seal 41 is radially or axially sleeved on the middle disk 37 . The compressor wheel 31, the compressor blade 32 and the compressor wheel cover 33 form a compressor impeller, and the compressor impeller is located in the compressor sealed chamber, the expander wheel 34, the expander blade 35 and the expander The wheel cover 36 forms the impeller of the expander, and the impeller of the expander is located in the sealed chamber of the expander. The impeller of the compressor and the impeller of the expander are arranged opposite to each other. As shown in Figure 1, the working medium of th...

Embodiment 2

[0030] Embodiment 2: as Figure 4 As shown, the disc includes a compressor disc 31, an expander disc 34 and a spacer 38, and the compressor disc 31 and the expander disc 34 are installed on both sides of the spacer 38 respectively, so The mechanical gap seal 41 is radially or axially sleeved on the spacer 38 . The compressor wheel 31 and the expander wheel 34 are processed separately, and then the two wheels are respectively installed on the spacer 38 to form an integral part. The spacer generally has a heat insulation function, and the compressor wheel 31 , the compressor blade 32 and the compressor wheel cover 33 form a compressor impeller, and the compressor impeller is located in the compressor seal cavity, and the expander wheel 34, the expander blade 35 and the expander wheel cover 36 form the expander impeller , and the expander impeller is located in the seal cavity of the expander, the compressor impeller and the expander impeller are arranged opposite to each other,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com