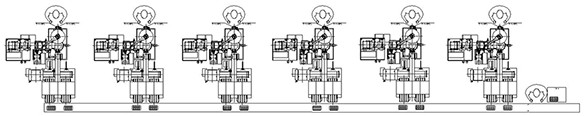

Adjustment method for improving automation degree of stuffed food stuffing pushing system

An adjustment method and food technology, applied in general control systems, control/regulation systems, program control, etc., can solve the difficulty of communication between checkweighers and equipment operators, reduce the degree of automation of production lines, and increase the degree of intervention of production line personnel. problems, to achieve the effect of reducing the degree of personnel intervention, reducing the demand for proficiency, and improving the stability of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the examples.

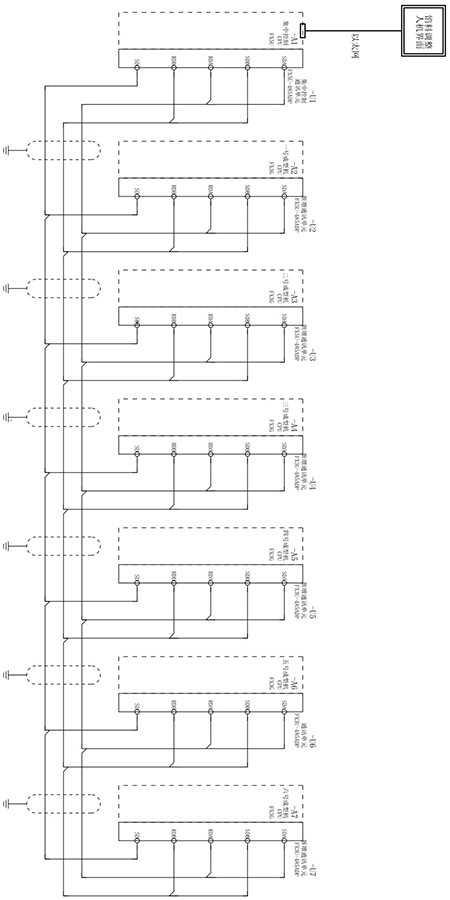

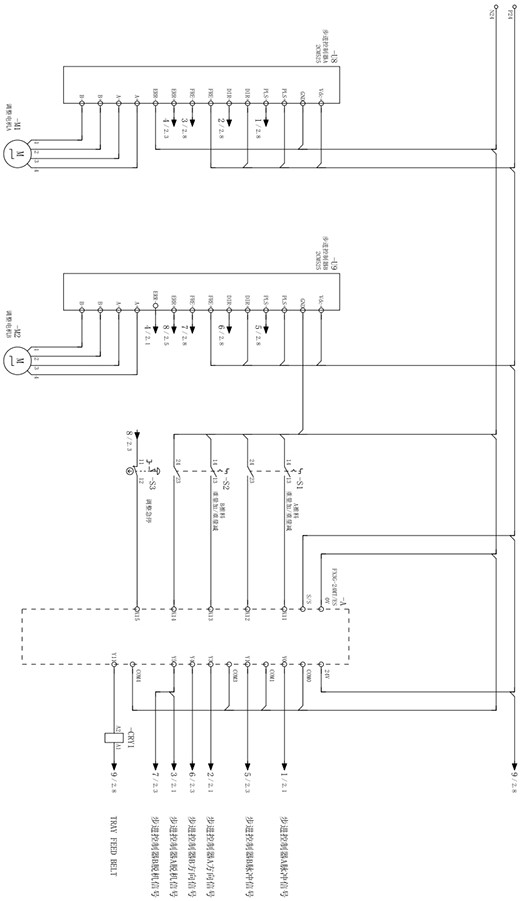

[0029] When the present invention is actually implemented, the purpose of the present invention is to address the above problems, and provide a method that can provide the actual product weight that needs to be adjusted when the check weigher detects that it does not need to use the equipment operator, and the check weigher can quickly, efficiently and conveniently Adjust the filling device of each filling product forming machine. Thereby reducing the amount of communication between the checkweigher and each equipment operator, reducing the labor intensity of the checkweigher and each equipment operator, reducing the amount of personnel intervention on the equipment, and improving the automation of the entire production line.

[0030] The technical scheme for realizing the above-mentioned purpose is:

[0031] An HMI (Human-Machine Interface) and PLC (Programmable Logic C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com