Device for eliminating static electricity on surface of polyimide film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

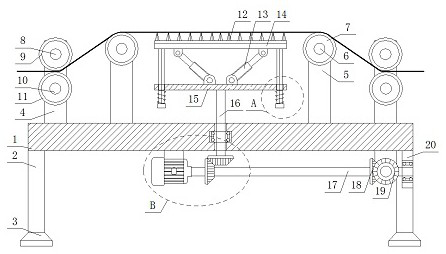

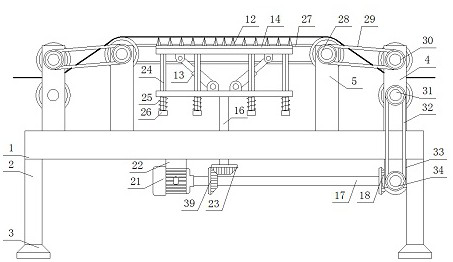

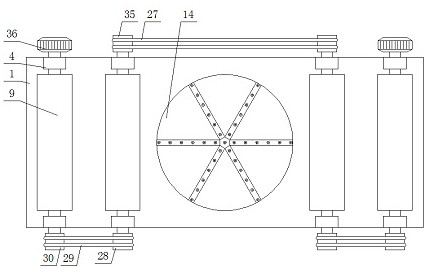

[0027] Such as Figure 1-6 As shown, a device for eliminating static electricity on the surface of a polyimide film includes a base plate 1, four corners of the bottom surface of the base plate 1 are fixed with support columns 2, and the bottom surface of each support column 2 is fixed with a base 3, the base The setting of 3 increases the stability of the overall device. A pair of symmetrical first vertical plates 4 are fixed at both ends of the top surface of the bottom plate 1, and a first rotating shaft 8 is arranged between each pair of first vertical plates 4. The two ends of the first rotating shaft 8 respectively pass through the corresponding two first vertical plates 4 and extend to the outside of the two first vertical plates 4, and the front end of each first rotating shaft 8 is fixed with a first linkage wheel 30, The rear end of each first rotating shaft 8 is all fixedly provided with interlocking bevel gear 36, and the bottom of each first rotating shaft 8 is al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com