Nitrification liquid bright backflow method

A technology of nitrifying liquid and return pipeline, which is applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc. Fluctuation and other problems can be achieved to ensure the denitrification efficiency, improve the wastewater treatment capacity, and improve the effect of backmixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

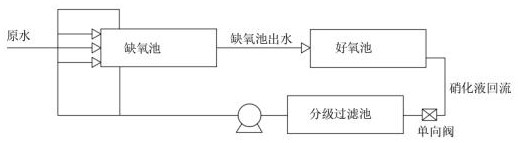

[0026] refer to image 3 As shown, the difference between this embodiment and other embodiments is that a graded filter tank is set under the aerobic tank, the graded filter tank is located between the nitrifying liquid pump and the aerobic tank, and multiple stages are connected to each other in the graded filter tank. The sedimentation chamber can be separated by partitions of different heights. The partitions are set from high to low from the liquid inlet to the liquid outlet, so as to play the role of graded sedimentation and ensure the nitrification in the lower sedimentation chamber. The impurity of the liquid is smaller than that of other sedimentation chambers, and the aerobic tank is connected with the graded filter tank through a pipeline, and the pipeline is used to lead out the nitrification liquid, and the nitrification liquid in the graded filter tank is supplied into the anoxic tank through the nitrification liquid pump;

[0027] The graded filter pool can filte...

Embodiment 2

[0029] refer to Figure 4 As shown, the difference between this embodiment and other embodiments is that a pneumatic pipeline is installed on the top of the anoxic tank, and the other end of the pneumatic pipeline is connected to a graded filter tank, and the gas in the anoxic tank can enter the graded filter through the pneumatic pipeline. pool;

[0030] When the sewage in the anoxic tank reacts, a large amount of gas will be produced. When the pressure reaches a certain level, the gas will be filled into the graded filter tank through the air pressure pipeline, which can increase the pressure in the graded filter tank, so that the nitrification hydraulic pressure in the graded filter tank can be reduced. Into the nitrifying liquid pump, reduce the working intensity of the nitrifying liquid pump, thereby further improving the service life of the nitrifying liquid pump, and can reduce energy consumption.

Embodiment 3

[0032] refer to Figure 5 As shown, the difference between this embodiment and other embodiments is that a quantitative tank is set between the anoxic tank and the nitrifying liquid pump, and the nitrifying liquid pump, the quantitative tank, and the aerobic tank are sequentially connected, and the quantitative tank acts as a Quantitative storage of nitrifying liquid;

[0033] Specifically, a float valve is installed in the quantitative tank, and a solenoid valve is installed on the pipeline connecting the anoxic tank and the quantitative tank. When the float valve reaches the limit liquid level, the solenoid valve will be opened, otherwise the solenoid valve will not be opened. , the float valve can be controlled by PLC. When the float valve reaches the limit liquid level, it means that the nitrifying liquid in the quantitative tank has reached the appropriate amount. At this time, the appropriate amount of nitrifying liquid in the quantitative tank can be sent to the anoxic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com