Steel sheet pile cofferdam supporting and anti-collision conversion structure and construction method

A steel sheet pile cofferdam and conversion structure technology, which is applied in the direction of basic structure engineering, bridge parts, erection/assembly of bridges, etc., can solve problems such as labor-intensive, increased steel sheet pile size, and affecting the construction space of the cap, and achieve structural Safe and reliable, tightly bonded effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

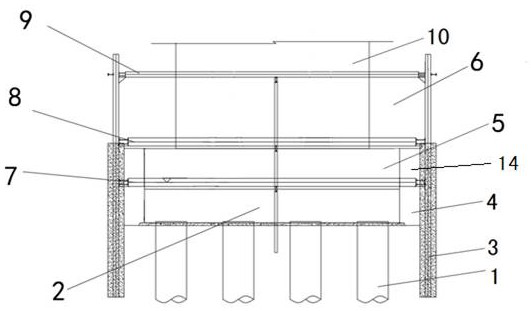

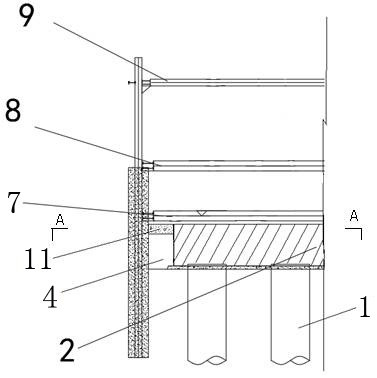

[0046] Embodiment 1: as Figure 1~5 As shown, the main bridge of Hegu Bridge is 420m long, and the span of the main bridge is (110+200+110)m. m, No. X cap platform is constructed with steel sheet pile cofferdam 3, and the plane size of the steel sheet pile cofferdam is 28.8m long and 22.8m wide. In the inner space 6 of the steel sheet pile cofferdam, there are three layers of inner support structures, which are the first inner support structure 7 , the second inner support structure 8 and the third inner support structure 9 . The first internal support structure 7 is 50cm above the top surface of the first cap 2. The first internal support structure 7 will affect the construction of the second cap 5. Therefore, before the construction of the second cap, it is necessary to dismantle the bottom surface of the steel sheet pile cofferdam The first internal support structure 7.

[0047] A construction method for steel sheet pile cofferdam support and anti-collision conversion str...

Embodiment 2

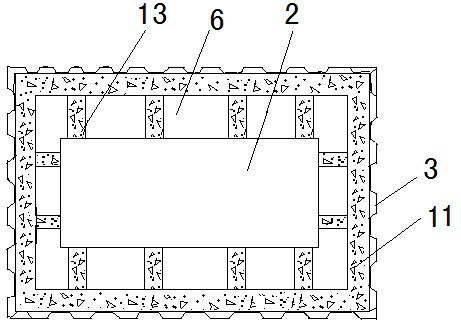

[0068] Embodiment 2: as Figure 1~5 As shown, the measured distance between the outer side of the first cap 2 and the second cap 5 and the inner wall of the corresponding steel sheet pile cofferdam is less than 1.2m.

[0069] Then, the construction method of the steel sheet pile cofferdam support and anti-collision conversion structure is as follows: according to the design, pile foundation 1 is built underground in the steel sheet pile cofferdam 3, and the upper end of the pile foundation is provided with caps, and the caps are poured in two layers. The pouring height of platform 2 is 2.5m, and the pouring height of second platform 5 is 3.2m. On the upper end of the pile foundation, the first cap 2 is first poured, and on the outer side of the upper part of the poured first cap, according to the height of the first concrete ring beam 11 of 50 cm, the butt joint on the inner side of the first concrete ring beam 11 is reserved to form the first concrete ring beam 11. Platform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com