Method for correcting and measuring mining and cutting curve of coal mining machine

A measuring method and a shearer technology, applied in the field of coal and rock cutting, can solve the problems of inability to identify the abnormal state of the drum, inability to meet the control requirements of the shearer, inability to adjust the traction speed and drum height adaptively, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

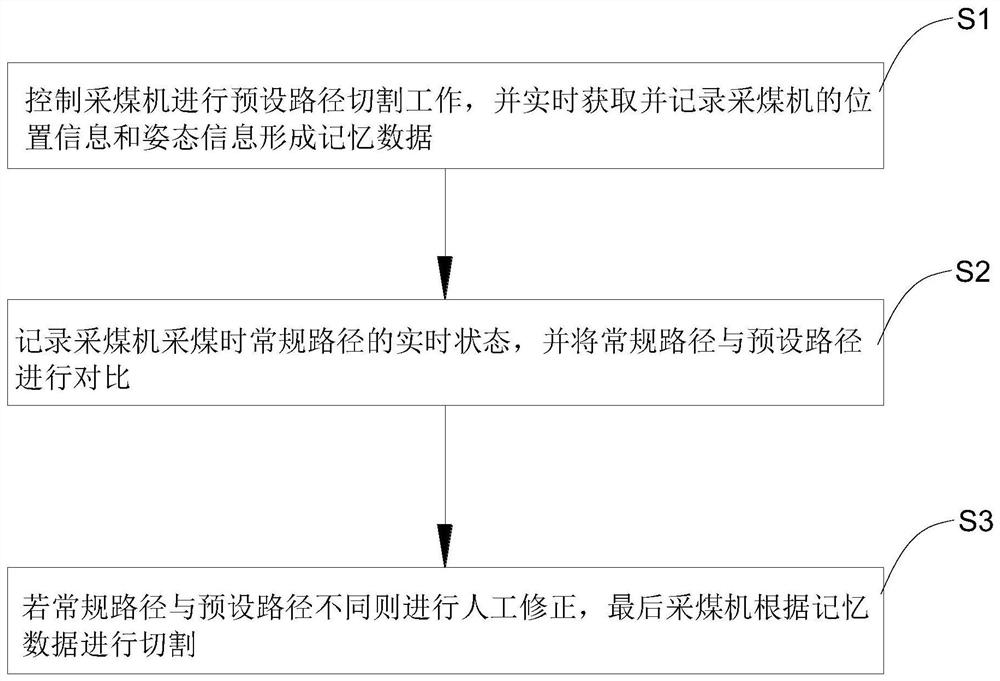

[0029] Please refer to figure 1 shown. This embodiment provides a shearer cutting curve correction measurement method, including the following steps: control the shearer to perform preset path cutting work, and acquire and record the position information and attitude information of the shearer in real time to form memory data; record The real-time status of the conventional path when the shearer is mining coal, and compare the conventional path with the preset path; if the conventional path is different from the preset path, it will be manually corrected, and finally the shearer will cut according to the memory data.

[0030] In the above-mentioned embodiment, the shearer is controlled to perform the cutting work on the preset path (the preset path is the optimal path, the path with the maximum coal mining efficiency). When the operator controls the shearer to cut, the onboard controller Record the current position information and attitude information of the shearer in time, ...

Embodiment 2

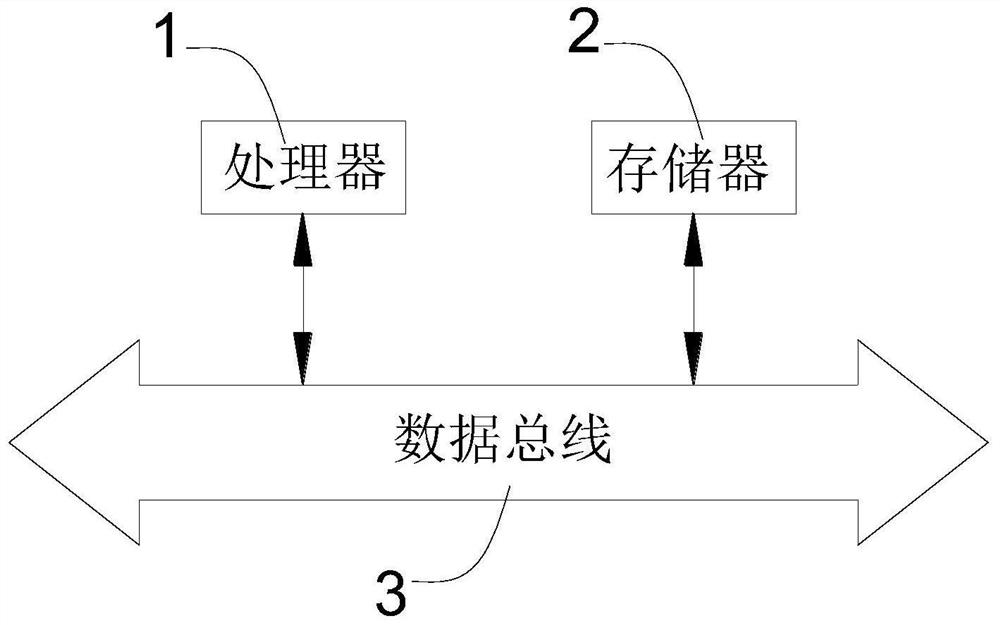

[0044] Please refer to figure 2 shown. An embodiment of the present application provides an electronic device, including: at least one processor 1, at least one memory 2, and a data bus 3; wherein: the processor 1 and the memory 2 communicate with each other through the data bus 3; The program instructions executed by the processor 1, the processor 1 invokes the program instructions to perform the method.

[0045] If the functions are implemented in the form of software function modules and sold or used as independent products, they can be stored in a computer-readable storage medium. Based on this understanding, the technical solution of the present application is essentially or the part that contributes to the prior art or the part of the technical solution can be embodied in the form of a software product, and the computer software product is stored in a storage medium, including Several instructions are used to make a computer device (which may be a personal computer, a...

Embodiment 3

[0047] An embodiment of the present application provides a non-transitory computer-readable storage medium, the non-transitory computer-readable storage medium stores a computer program, and the computer program enables a computer to execute a method.

[0048] In summary, the first aspect: the embodiment of the present invention provides a shearer cutting curve correction measurement method, including the following steps: controlling the shearer to perform preset path cutting work, and obtaining and recording the position of the shearer in real time Information and attitude information form memory data; record the real-time state of the conventional path of the shearer during coal mining, and compare the conventional path with the preset path; if the conventional path is different from the preset path, manually correct it, and finally the shearer according to Memory data for cutting.

[0049] In the above-mentioned embodiment, the shearer is controlled to perform the cutting w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com