Universal waste heat exchanger

A heat exchanger, general-purpose technology, used in household heating, applications, heating fuels, etc., can solve the problem of low heating efficiency, and achieve the effect of maximizing heat exchange and achieving remarkable results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

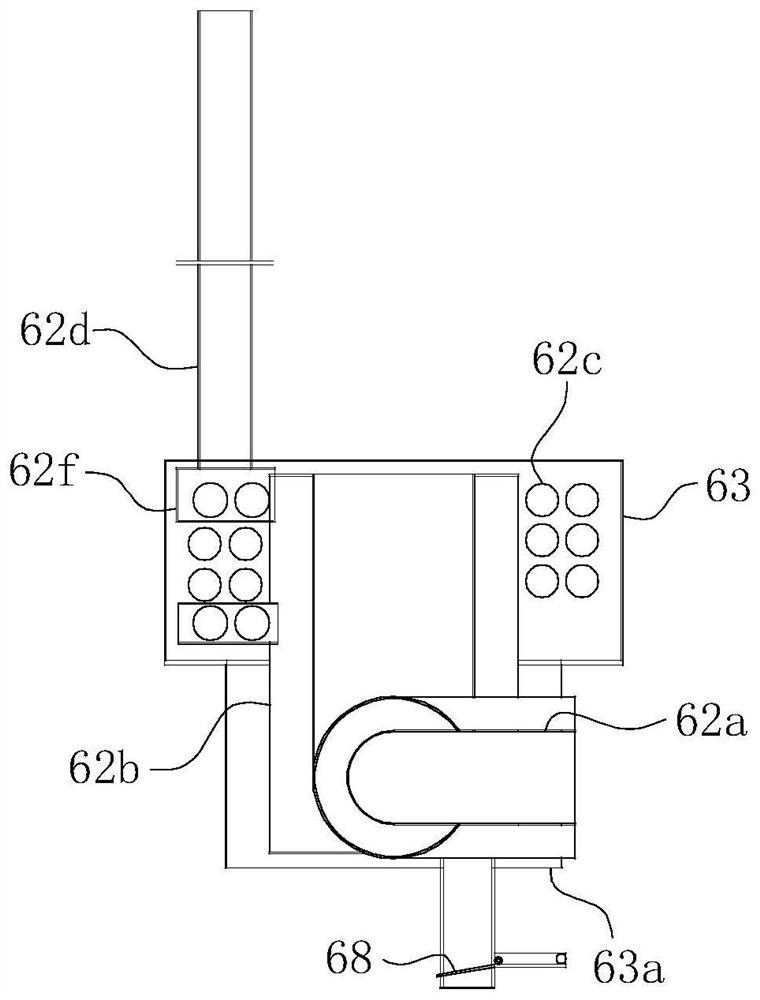

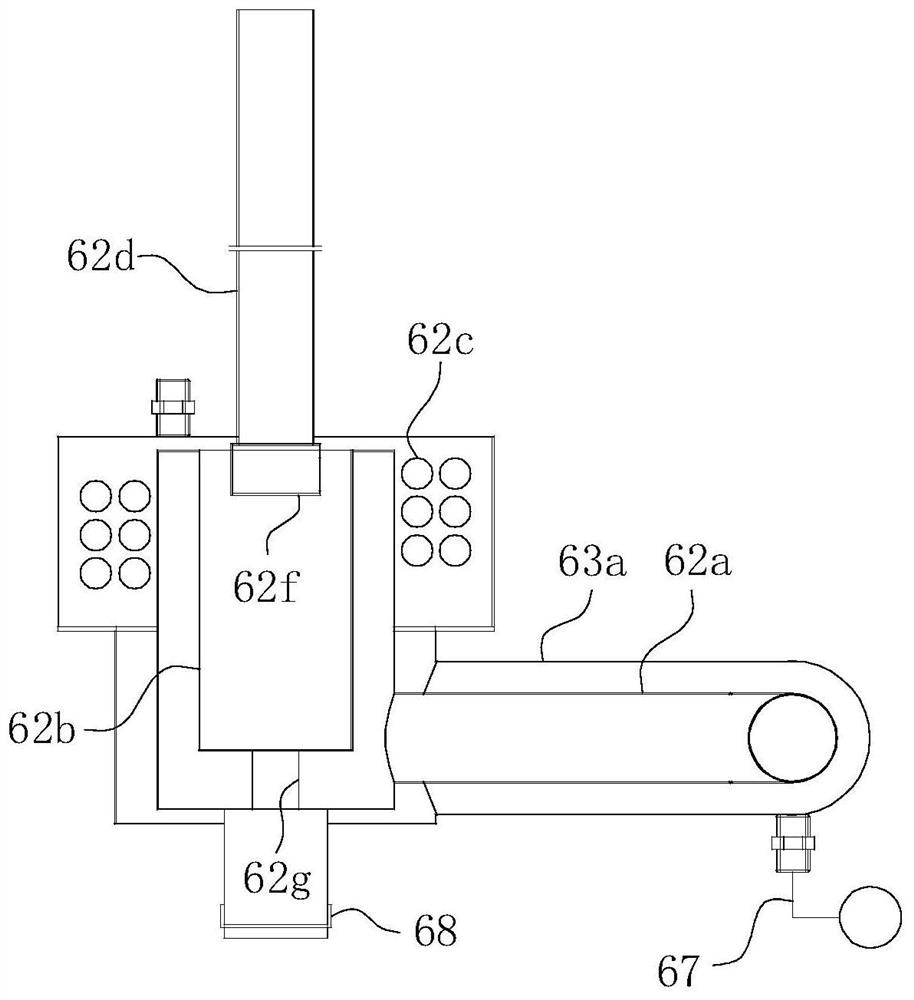

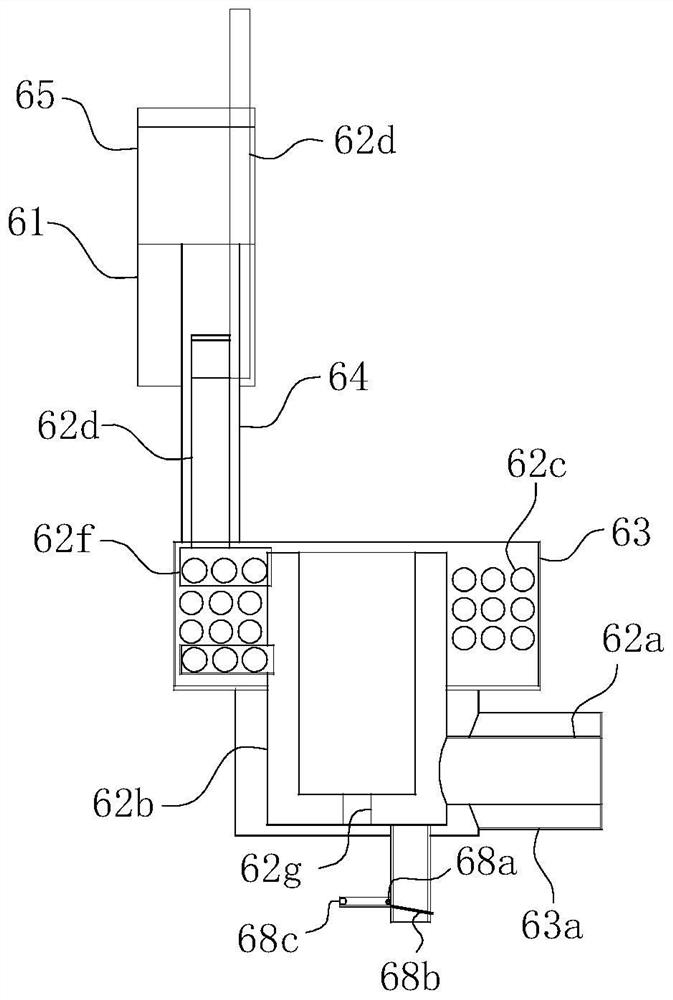

[0035] For ease of understanding, combined here Figure 1-5 , the concrete structure and working mode of the present invention are further described as follows:

[0036] The present invention depends on the difference of on-site application objects, such as Figure 1-2 The hot water type heat exchanger shown and the Figure 3-4 Two specific implementation classes of steam-type heat exchangers are shown. As the name implies, the hot water heat exchanger is used to realize the design function of turning waste heat into hot water, while the steam heat exchanger further realizes the design purpose of turning waste heat into steam. For the steam type heat exchanger, compared with the hot water type heat exchanger, such as steam discharge pipe 64, return water pipe 66 and even water vapor separation baffle 65a are added; because the structure is relatively more complicated, the steam Type heat exchanger is described as follows to the practical application structure of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com