Multi-component relaxor ferroelectric film material with superlattice structure and ultrahigh energy storage efficiency and preparation method of multi-component relaxor ferroelectric film material

A technology of ferroelectric thin film and energy storage efficiency, applied in circuits, capacitors, electrical components, etc., can solve the problems of poor energy storage density and energy storage efficiency, and achieve excellent energy storage density, energy storage efficiency, and energy storage performance Good and stable, the effect of energy storage performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

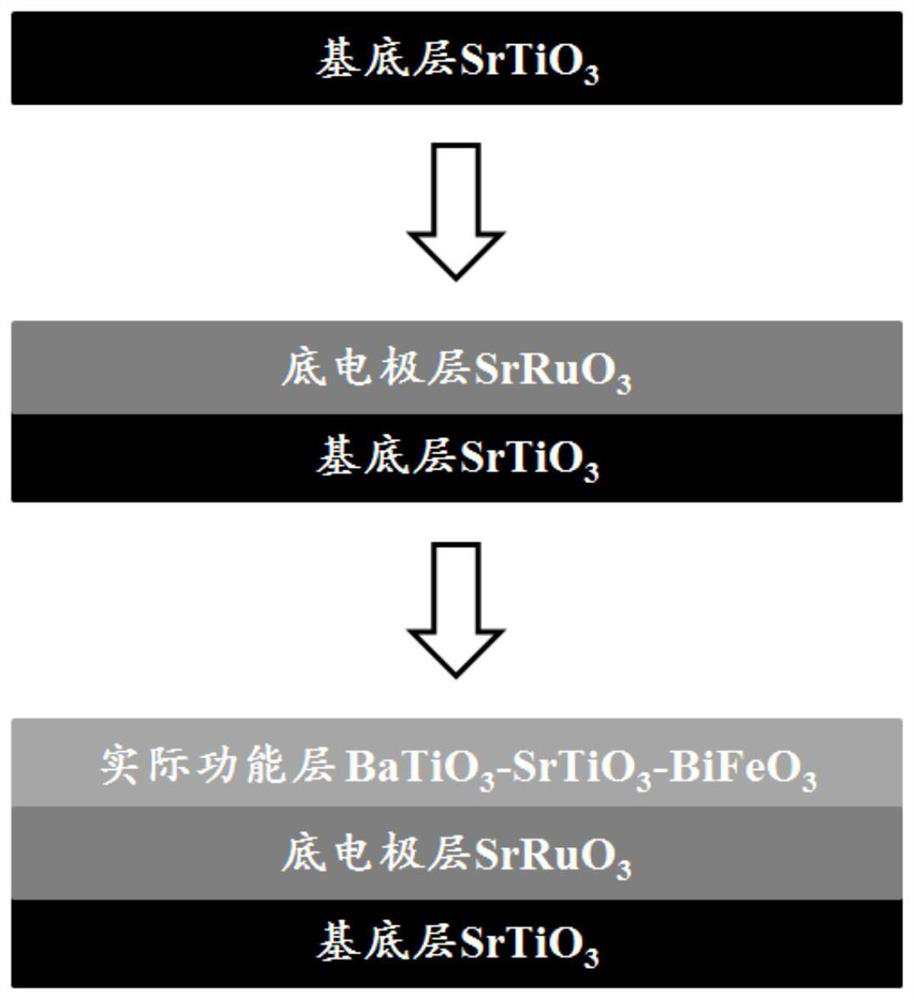

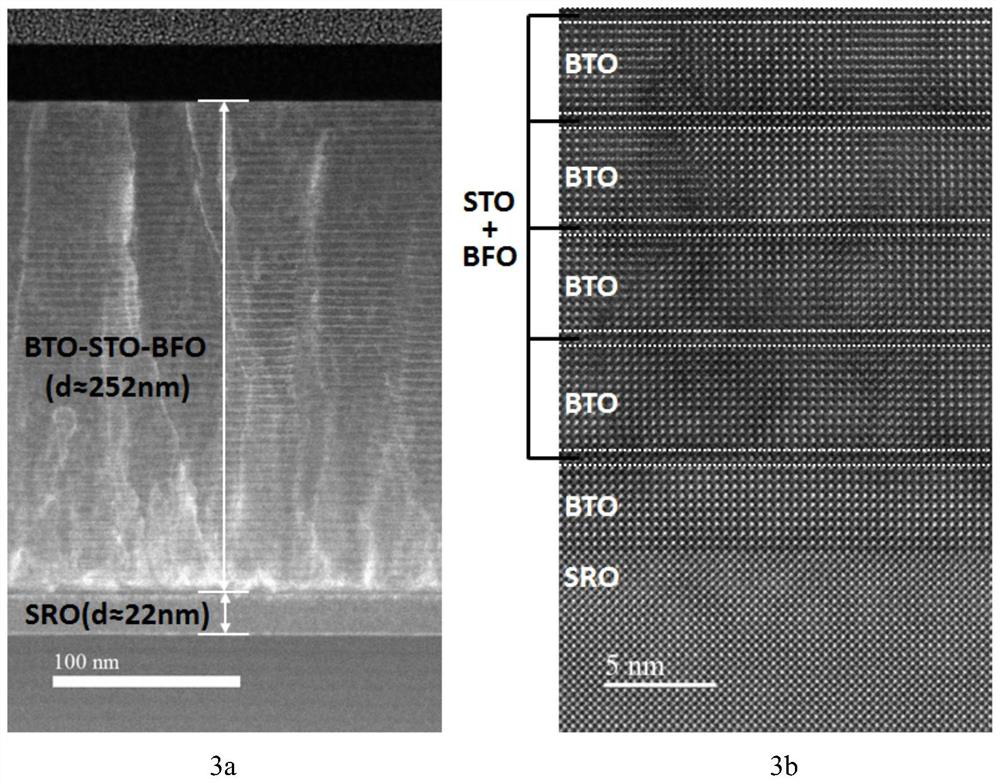

[0061] A multi-component relaxor ferroelectric thin film material with a superlattice structure and ultrahigh energy storage efficiency, comprising: a base layer, a bottom electrode layer formed on the base layer, and an actual functional layer formed on the bottom electrode layer, The actual functional layer is a superlattice structure formed by repeated multi-period superimposition of a multi-layer structure film with relaxor ferroelectricity grown on the bottom electrode layer. In this embodiment, the repetition period N=40.

[0062] Such as figure 1 As shown, the preparation method of the above-mentioned multi-component relaxation ferroelectric thin film material comprises the following steps:

[0063] (1) Select the base layer, the base layer is rigid SrTiO 3 (STO) substrate, the crystal plane orientation of the STO substrate is [100].

[0064] (2) Using a pulsed laser deposition system to deposit SrRuO on the STO substrate layer 3 The (SRO) layer is used as the bottom...

Embodiment 2

[0080] The difference from Example 1 is that the fixed number of rounds for bombarding the BTO target in step C is 240 rounds, the fixed number of rounds for bombarding the STO target in step D is 40 rounds, and the fixed number of rounds for bombarding the BFO target in step E is 20 rounds. The process of cycling steps C to E was repeated 50 times to obtain a BTO-STO-BFO multi-component relaxor ferroelectric thin film material with a repetition period of N=50.

Embodiment 3

[0082] The difference from Example 1 is that the fixed number of rounds for bombarding the BTO target in step C is 200 rounds, the fixed number of rounds for bombarding the STO target in step D is 33 rounds, and the fixed number of rounds for bombarding the BFO target in step E is 17 rounds. The process of cycling steps C to E was repeated 60 times to obtain a BTO-STO-BFO multi-component relaxor ferroelectric thin film material with a repetition period of N=60.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com