Novel stator structure based on axial flux motor

A technology of axial magnetic flux and stator structure, applied in the shape/pattern/structure of magnetic circuit, shape/pattern/structure of winding insulation, shape/pattern/structure of winding conductor, etc. Problems such as difficult processing and assembly, to achieve good mechanical strength and heat dissipation characteristics, low cost, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

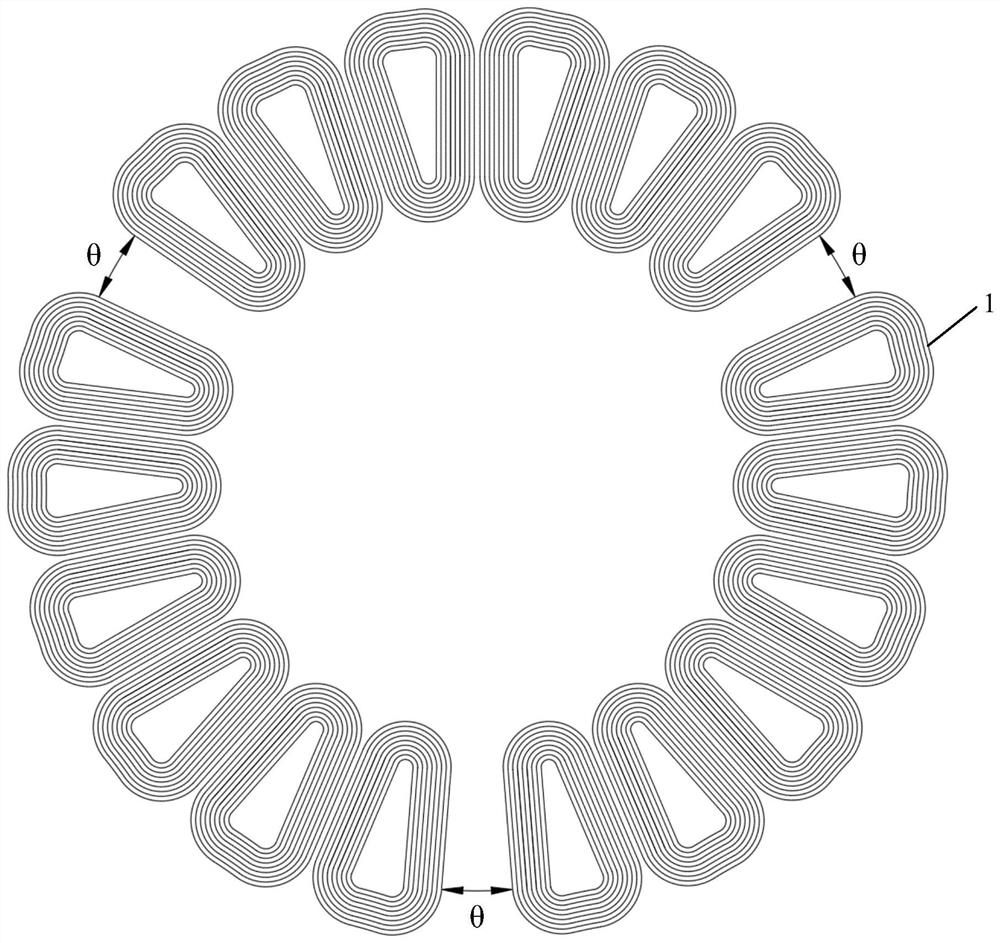

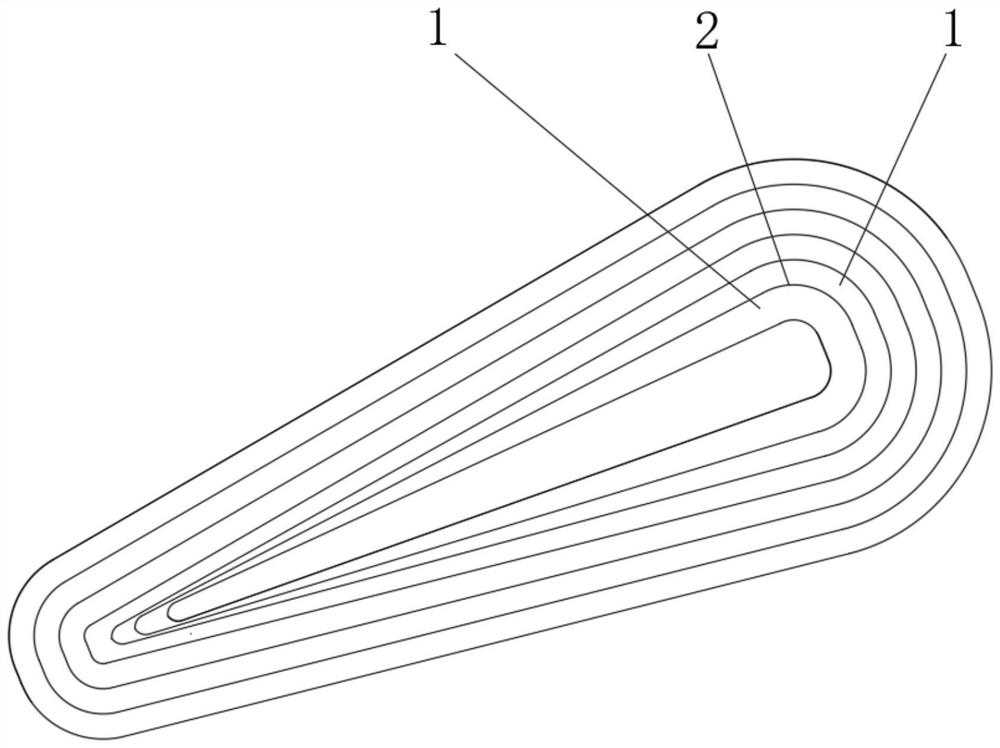

[0023] refer to Figure 1-Figure 2 , this embodiment discloses a new stator structure based on an axial flux motor, which includes more than three coil monomers of the same specification distributed in the stator in a ring. Taking a three-phase motor as an example, the coil monomers in this embodiment It is the coil monomer inside the axial ironless motor, that is, the material of the stator core 3 is air, and the coil monomer is wound by a plurality of enameled wires 1, and there is an insulating material 2 between two adjacent enameled wires 1, and the insulating material 2 Form inter-turn insulation, separate the conductors with different potentials in the motor winding from each other, so as to avoid inter-turn short circuit, each adjacent N coil monomers form a coil unit, and there are three coil units in the stator. The included angle between two adjacent coil units is θ, and the value range of θ is 2-35 degrees. The coil monomers in each coil unit are uniformly distribu...

Embodiment 2

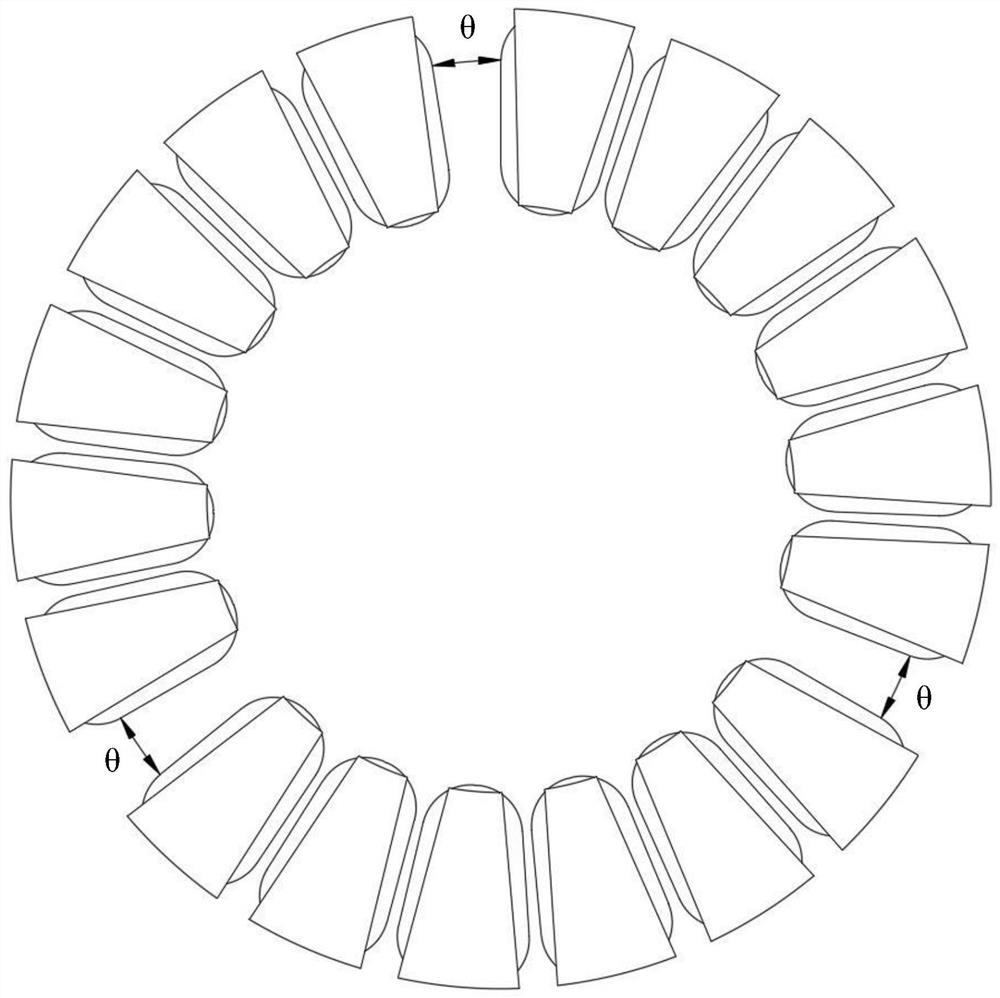

[0025] refer to Figure 3-Figure 4 , this embodiment discloses a new stator structure based on an axial flux motor, which includes more than three coil monomers of the same specification distributed in the stator in a ring. Taking a three-phase motor as an example, the coil monomers in this embodiment It is a single coil inside the axial iron core motor, which is composed of a stator core 3 and a winding 4 wound on the stator core 3. The material of the stator core 3 is selected from one of iron, magnetic powder core and soft magnetic composite material. The winding 4 is made of enameled wire 1 with an insulating layer; the stator core 3 and the winding 4 are separated by insulating paper or insulating varnish to avoid electrical connection between the winding 4 and the stator core 3 . The coil monomers that make up the stator are arranged in a ring-shaped and non-uniform manner. Every adjacent N coil monomers form a coil unit. There are three coil units in the stator. The ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com