Crosslinked polybenzimidazole membrane material for high-temperature proton exchange membrane and preparation method of cross-linked polybenzimidazole membrane material

A technology of proton exchange membrane and polybenzimidazole, which is applied in the field of high temperature proton exchange membrane materials and its preparation, can solve the problems of deterioration of PBI membrane mechanical strength and reduction of PBI polymer chain interaction force, and achieve mechanical properties and Improved dimensional stability, improved proton conductivity, and simple cross-linking process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

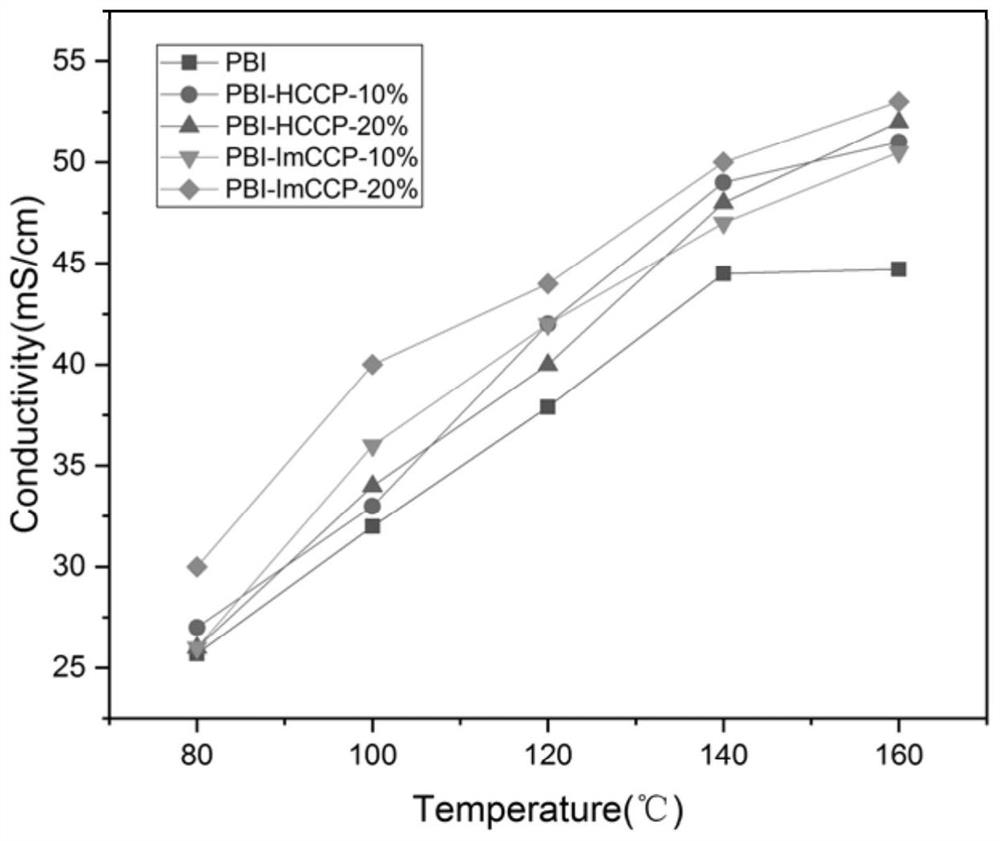

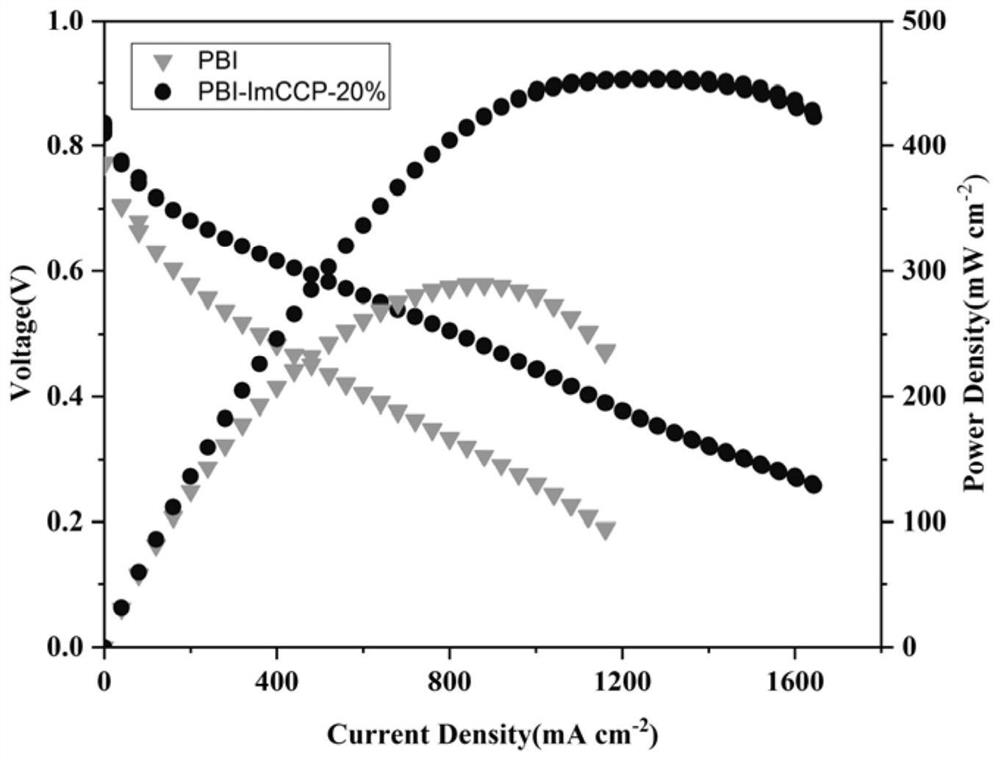

[0029] Embodiment 1: The preparation method of PBI-HCCP-10% high temperature proton exchange membrane material is as follows:

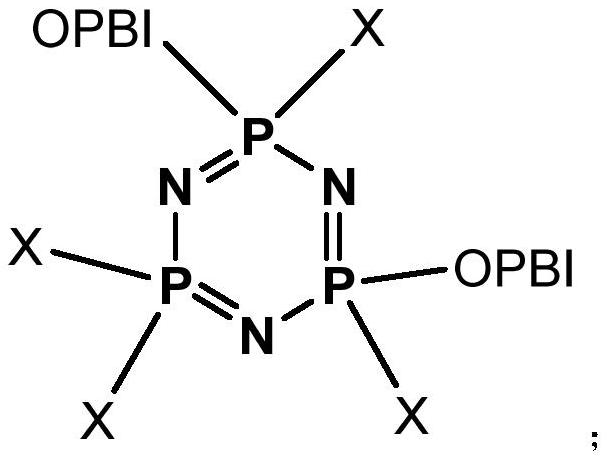

[0030] Add the polybenzimidazole resin to the N-methylpyrrolidone solution, heat and stir to dissolve it, and obtain a polymer solution with a mass fraction of 5 wt %; add hexachlorocyclotriphosphazene to the N-methylpyrrolidone solution, and stir to make It dissolves to obtain a solution with a mass fraction of 1% by weight; the molar ratio of the hexachlorocyclotriphosphazene and the imidazole ring in polybenzimidazole is controlled to be 1:60, that is, 10% of the imidazole ring undergoes a nucleophilic substitution reaction; the hexachlorocyclotriphosphazene Cyclotriphosphazene solution was added dropwise to the polybenzimidazole solution to finally obtain a uniform solution containing a cross-linking agent; the solution casting film-forming method was used to pour the uniform solution containing a cross-linking agent on a glass plate and heat at 80...

Embodiment 2

[0031] Embodiment 2: The preparation method of PBI-HCCP-20% high temperature proton exchange membrane material is as follows:

[0032] Add the polybenzimidazole resin to the N-methylpyrrolidone solution, heat and stir to dissolve it, and obtain a polymer solution with a mass fraction of 5 wt %; add hexachlorocyclotriphosphazene to the N-methylpyrrolidone solution, and stir to make It dissolves to obtain a solution with a mass fraction of 1% by weight; the molar ratio of the hexachlorocyclotriphosphazene and the imidazole ring in the polybenzimidazole is controlled to be 1:30, that is, 20% of the imidazole ring undergoes a nucleophilic substitution reaction; the hexachlorocyclotriphosphazene Cyclotriphosphazene solution was added dropwise to the polybenzimidazole solution to obtain a uniform solution containing a cross-linking agent; the solution casting film-forming method was used to cast the uniform solution containing a cross-linking agent on a glass plate and heated at 80°C...

Embodiment 3

[0033] Embodiment 3: The preparation method of PBI-ImCCP-10% high temperature proton exchange membrane material is as follows:

[0034] Add the polybenzimidazole resin to the N-methylpyrrolidone solution, heat and stir to dissolve it, and obtain a polymer solution with a mass fraction of 5 wt %; add hexachlorocyclotriphosphazene to the N-methylpyrrolidone solution, and stir to make It dissolves to obtain a solution with a mass fraction of 2wt%; add imidazole into the N-methylpyrrolidone solution, stir to dissolve it, and obtain a solution with a mass fraction of 2wt%; at 30°C, add 3g of the imidazole solution dropwise to In 5.1g of hexachlorocyclotriphosphazene solution, continue to stir for 30min after the dropwise addition to prepare imidazole-chlorocyclotriphosphazene solution; The molar ratio is 1:10, that is, 10% of the imidazole ring undergoes a nucleophilic substitution reaction; then the imidazole-chlorocyclotriphosphazene solution is added dropwise to the polybenzimid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com