Starch-based fully-degradable PBAT master batch capable of being mixed for use as well as preparation method and application thereof

A starch-based, fully degradable technology, applied in the field of degradable polymer materials, can solve the problems of insufficient yield strength and sealing strength of PBAT, and achieve the effects of low comprehensive cost, reduced processing cost and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

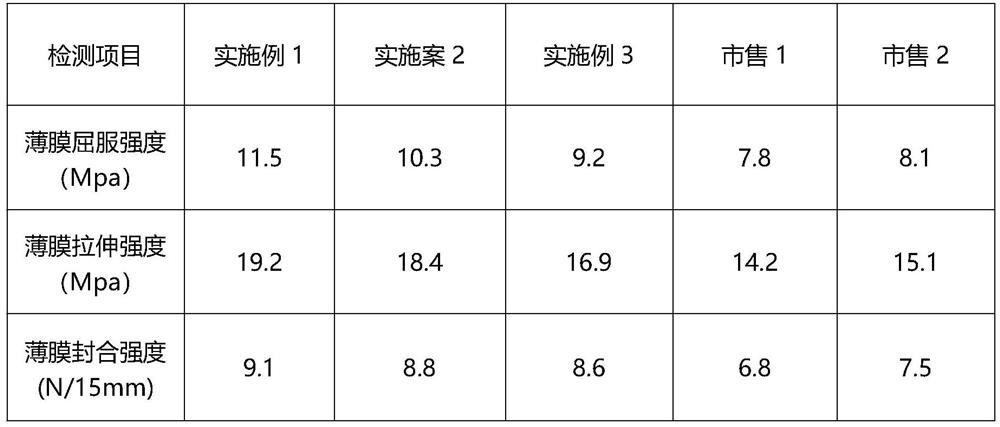

Examples

Embodiment 1

[0050] A fully degradable starch-based PBAT masterbatch that can be mixed and used, comprising 42% starch, 9% glycerin, 44.3% PBAT, 1.5% heat stabilizer, 0.6% lubricant, 2% auxiliary plasticizer, anti Oxygen agent 0.3%, chain extender 0.3%.

[0051] According to the following method, the starch-based fully degradable PBAT masterbatch that can be mixed and used is obtained, and the specific steps are as follows: (1) starch

[0052]Pour the powder into the high mixer, add glycerin at a speed of 200r / min, continue to stir for 2min, and stop stirring;

[0053] (2) Add PBAT and heat stabilizer, lubricant, auxiliary plasticizer, antioxidant, chain extender and other additives, and stir at 450r / min for 2min;

[0054] (3) Extrude and granulate the mixture obtained above through a twin-screw extruder at an extrusion temperature of 130° C. to obtain starch-based fully degradable PBAT masterbatch granules.

[0055] Prepare the modified starch-based PBAT biodegradable film material with...

Embodiment 2

[0059] A fully degradable starch-based PBAT masterbatch that can be mixed and used, comprising 36% starch, 7% glycerin, 53.3% PBAT, 1.5% heat stabilizer, 0.6% lubricant, 2% auxiliary plasticizer, anti Oxygen agent 0.3%, chain extender 0.3%.

[0060] According to the following method, the starch-based fully degradable PBAT masterbatch that can be mixed and used is obtained, and the specific steps are as follows: (1) starch

[0061] Pour the powder into the high mixer, add glycerin at a speed of 200r / min, continue to stir for 2min, and stop stirring;

[0062] (2) Add PBAT and heat stabilizer, lubricant, auxiliary plasticizer, antioxidant, chain extender and other additives, and stir at 450r / min for 2min;

[0063] (3) Extrude and granulate the mixture obtained above through a twin-screw extruder at an extrusion temperature of 130° C. to obtain starch-based fully degradable PBAT masterbatch granules.

[0064] Prepare the modified starch-based PBAT biodegradable film material wit...

Embodiment 3

[0068] A fully degradable starch-based PBAT masterbatch that can be mixed and used, comprising 32% starch, 6% glycerin, 57.3% PBAT, 1.5% heat stabilizer, 0.6% lubricant, 2% auxiliary plasticizer, anti Oxygen agent 0.3%, chain extender 0.3%. According to the following method, the starch-based fully degradable PBAT masterbatch that can be mixed and used is obtained, and the specific steps are as follows: (1) starch

[0069] Pour the powder into the high mixer, add glycerin at a speed of 200r / min, continue to stir for 2min, and stop stirring;

[0070] (2) Add PBAT and heat stabilizer, lubricant, auxiliary plasticizer, antioxidant, chain extender and other additives, and stir at 450r / min for 2min;

[0071] (3) Extrude and granulate the mixture obtained above through a twin-screw extruder at an extrusion temperature of 130° C. to obtain starch-based fully degradable PBAT masterbatch granules.

[0072] Prepare the modified starch-based PBAT biodegradable film material with the obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com