Intelligent transformation method for ventilation system of underground powerhouse of hydropower station

A technology for ventilation systems and underground workshops, applied in heating and ventilation control systems, heating and ventilation safety systems, hydroelectric power stations, etc. Hot, humid and other problems, to achieve the effect of high degree of automation and intelligence, meet the requirements of production and operation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

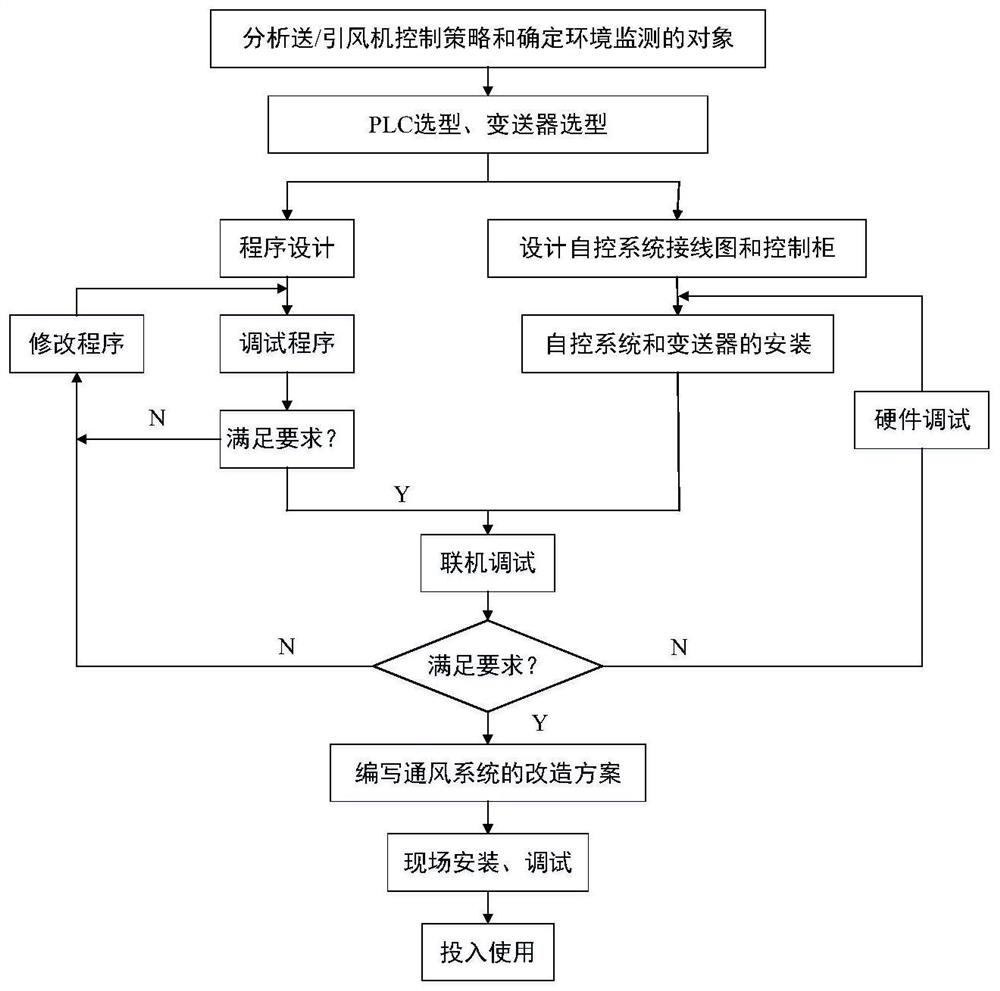

[0029] refer to Figure 1 ~ Figure 4 , which is the first embodiment of the present invention, provides a method for intelligent transformation of the ventilation system of an underground powerhouse of a hydropower station, including:

[0030] S1: Analyze the system requirements according to the actual situation on site.

[0031] S2: Build the control system and transmitter in the hardware equipment.

[0032] S3: Build the lower computer program, develop the upper computer software, and then jointly debug with the hardware equipment.

[0033] S4: Conduct joint debugging of the entire system, write the construction plan of the online monitoring system, and carry out on-site construction and debugging.

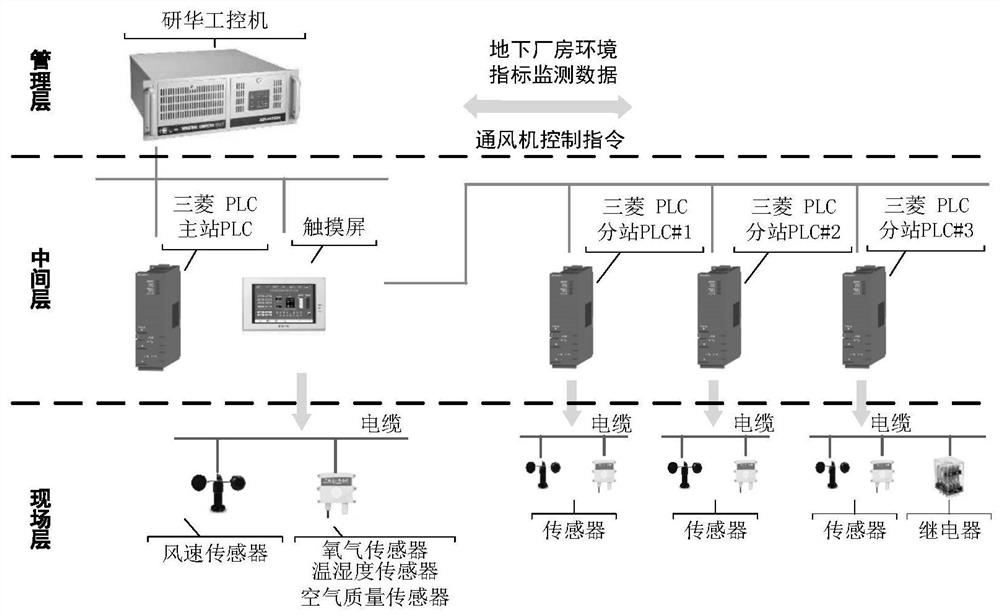

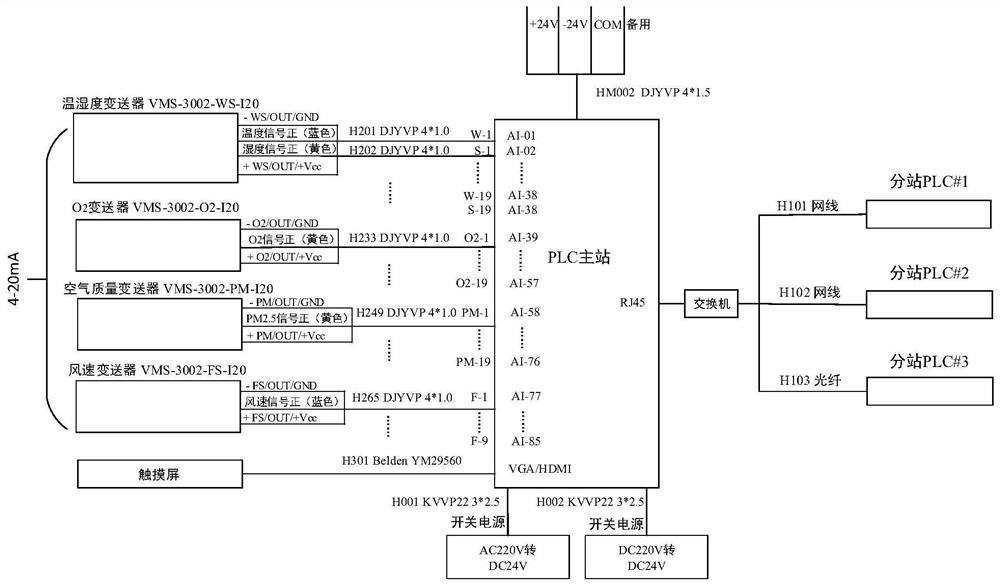

[0034] refer to figure 2 , the hardware equipment adopts a distributed architecture, which is divided into three layers, including the management layer, the middle layer and the field layer; the PLCs in the middle layer are connected by Ethernet or optical fiber, and each PL...

Embodiment 2

[0057] refer to Figure 5 , which is the second embodiment of the present invention. This embodiment is different from the first embodiment in that it provides an online monitoring system software design for the ventilation system of the underground powerhouse of a hydropower station, which specifically includes:

[0058] The online monitoring system software design consists of two parts: the upper computer and the lower computer. The upper computer is the control object, usually an industrial computer or server, and its function is to directly issue operation commands; the lower computer is the controlled object, usually PLC and other intelligent modules. , whose function is to directly control the device and read the device status.

[0059] Preferably, for the online monitoring system, the host computer part is based on Kingview monitoring software, develops a human-computer interactive visual interface, and obtains real-time environmental data of the underground plant by co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com