Walnut airing device

A drying device and technology for walnuts, applied in lighting and heating equipment, drying, furnace types, etc., can solve the problems that walnuts cannot get enough sunlight and low space utilization, so as to improve space utilization, increase conversion rate, Solve the effect of low space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

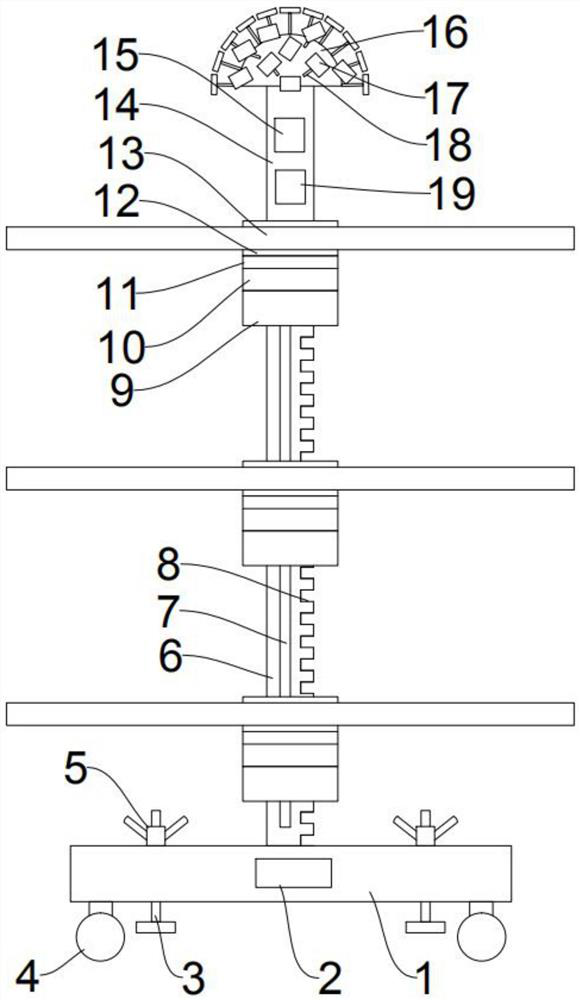

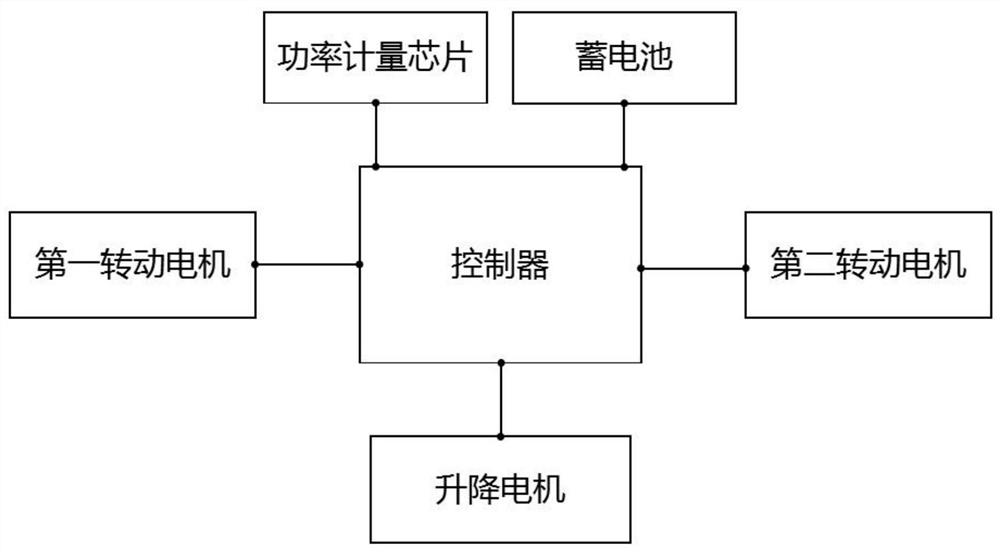

[0038] For ease of understanding, see Figure 1 to Figure 4 , an embodiment of a walnut drying device provided by the present application, including a drying mechanism, a direct sunlight angle monitoring system and a controller 2.

[0039] The airing mechanism comprises a base 1, a slide bar 6, a plurality of lift motors 9 and a storage unit for use in conjunction.

[0040] The bottom of the slide bar 6 is connected with the top of the base 1, and the lift motor 9 is sleeved on the slide bar 6, and the lift motor 9 can slide up and down along the slide bar 6.

[0041] The storage unit includes a storage basket 13, a basket cover 26, a first rotating motor 10 whose rotating shaft is arranged vertically and rotates horizontally and a second rotating motor 12 whose rotating shaft is arranged horizontally and rotating vertically, the first rotating motor 10 and the second rotating motor 12 Sleeved on the slide bar 6 , the first rotating motor 10 is connected to the lifting motor ...

Embodiment 2

[0050] For ease of understanding, see Figure 1 to Figure 4 , present embodiment is as the further improvement of a kind of walnut drying device in embodiment 1, is provided with chute 7 vertically on the slide bar 6, is provided with the slide block that cooperates with chute 7 on the lifting motor 9.

[0051] The slide bar 6 is provided with a tooth pattern 8, and the lifting motor 9 is provided with a gear meshed with the tooth pattern 8.

[0052] The shapes of the lifting motor 9 and the first rotating motor 10 are all cylindrical, and the slide bar 6 is a circular bar.

[0053] It should be noted that the sliding block of the lifting motor 9 slides in the chute 7 of the sliding rod 6 , so that the lifting motor 9 is not easy to deviate on the sliding rod 6 . The gear of the lifting motor 9 meshes with the tooth pattern 8 of the slide bar 6, no matter which position the lifting motor 9 lifts to, it can obtain a better focus point, and the lifting motor 9 is not easy to sl...

Embodiment 3

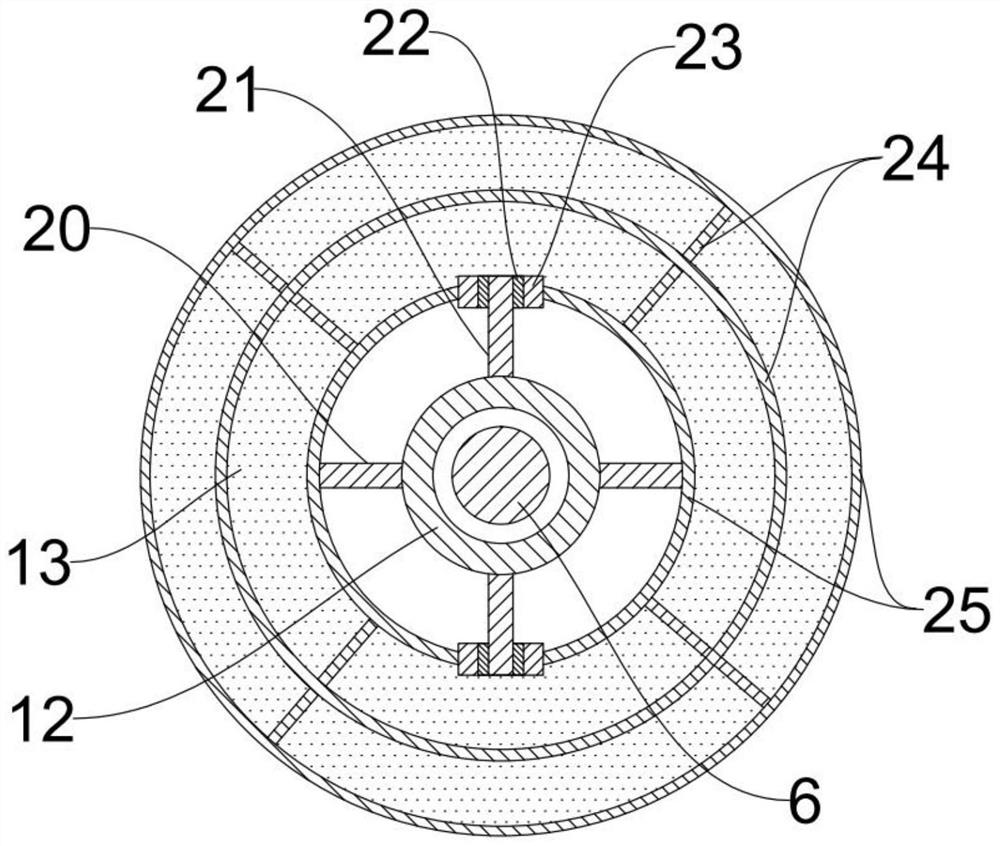

[0055] For ease of understanding, see Figure 1 to Figure 4 In this embodiment, as a further improvement of the walnut drying device in Embodiment 1, the shape of the storage basket 13 is disc-shaped.

[0056] The storage basket 13 is vertically provided with a frame 25 and an isolation plate 24 , and the isolation plate 24 is arranged symmetrically about the center of the storage basket 13 .

[0057] The bottom of the storage basket 13 is provided with a plurality of grooves 27 for placing walnuts.

[0058] It should be noted that when the disk-shaped storage basket 13 is rotated, the forces in all directions are balanced, and the rotation of the storage basket 13 is not easily affected by unbalanced forces. The frame 25 and the separating plate 24 are set on the storage basket 13, which can prevent the walnuts from falling, and can also prevent the walnuts from gathering together, which affects the drying effect. When the bottom of the walnut was embedded in the bottom gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com