Centrifugal activated carbon dust purification system and purification method thereof

A dust purification and activated carbon technology, applied in separation methods, chemical instruments and methods, combustible gas purification, etc., can solve the problems of affecting system safety, difficult to remove, and increase the dust content of the outlet, so as to ensure the air washing effect and improve the dust purification. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

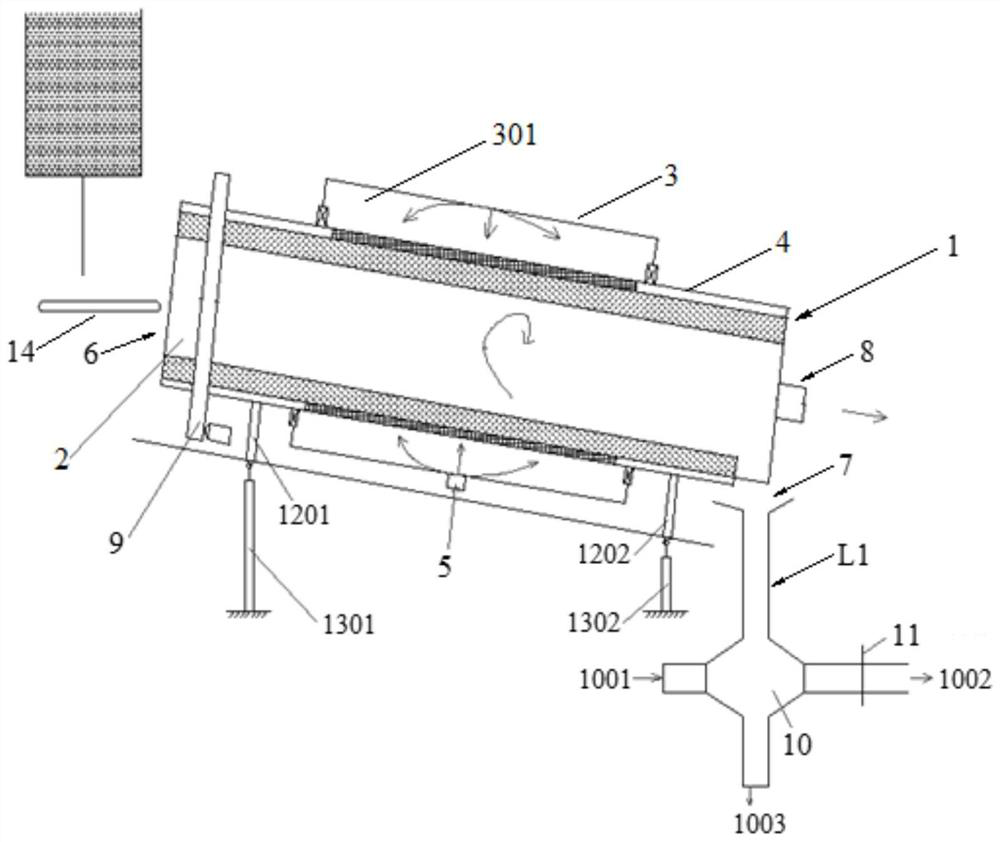

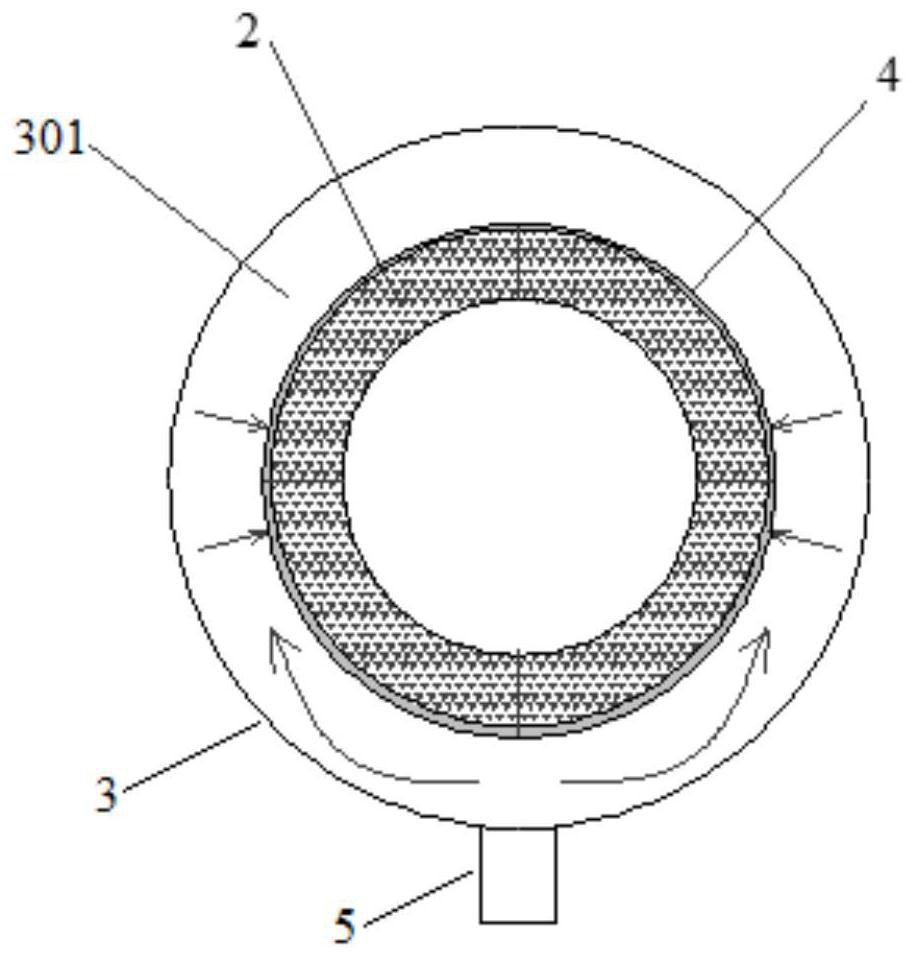

[0069] According to a first embodiment of the present invention, a centrifugal activated carbon dust purification system is provided.

[0070] A centrifugal dust activated carbon purification system, the system comprising a rotary cylinder. The internal space of the rotary cylinder 1 constitutes a wind washing chamber 2. The outer portion of the rotary cylindrical 1 is provided with a wind chamber 3 and the outer wall of the wind chamber 3 and the outer wall of the rotary cylinder 1. A porous distribution plate 4 is provided between the wind ishing chamber 2 and the wind chamber 301. Rotary cylinder 1 tilt setting. The bottom center position of the wind chamber 3 is provided with a central winding fan 5. The rotary cylinder 1 is provided with the active carbon feed port 6 at a higher level of the horizontal position, and the active charcoal tube opening 7 is provided at a lower portion of the horizontal position, and a smoke is provided at a side of the horizontal position. Outlet...

Embodiment 1

[0104] like figure 1 and 2 Shown, a centrifugal dust activated carbon purification system, the system comprising a rotary cylinder. The interior space of the rotary cylinder 1 constituting the air chamber 2 wash. A rotary cylinder provided with an external air discharging chamber cover 3, the cover 3 constitute air chamber 301 between the air chamber 1 and the outer wall of the rotary cylinder. 4 is provided with perforated distribution plate 301 between the air chamber 2 and wind wash chamber. An inclined rotary cylinder. Center of the bottom cover 3 position of the air chamber provided with a central cabin unit 5. A rotary cylinder in a horizontal position of the upper side end portion of the feed port 6 is provided with activated carbon, in a lower portion of the horizontal position of the lower end of the discharge port 7 is provided with activated carbon, the lower end of the side portion of the flue gas is provided in a horizontal position exit 8. The system 1 further compri...

Embodiment 2

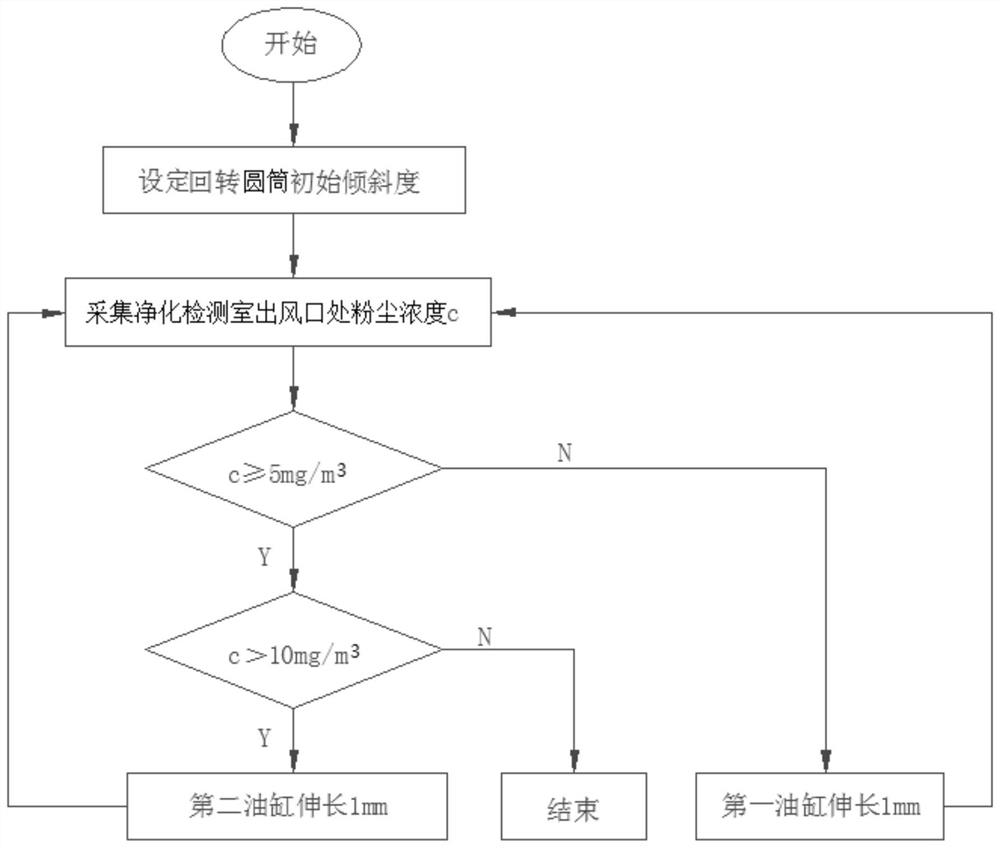

[0106] Example 1 was repeated, except that the system further comprises activated carbon discharge port 7 connected to the discharge path L1, the discharge passage L1 is connected to the other end of the detection chamber 10 to purge dust. The dust detection chamber 10 is provided with purge air inlet 1001, the outlet 1002 and outlet 1003 of activated carbon. Purifying the dust detection chamber 1002 from outlet dust concentration detection device 11 is provided with 10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com