Room-pillar goaf control filling key parameter design method

A technology of key parameters and design methods, which is applied to filling materials, mining equipment, earthwork drilling and mining, etc., can solve the problems of large filling grouting volume, and does not consider the bearing performance of the remaining coal pillars, so as to reduce the filling cost and improve the filling effect , the effect of reducing the amount of design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

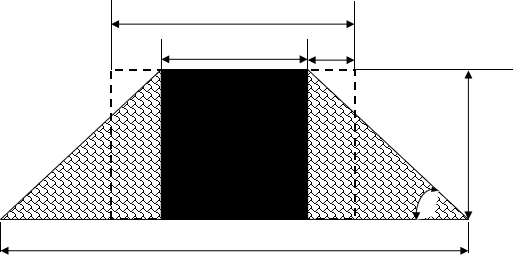

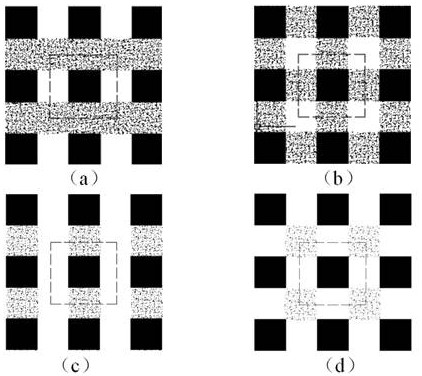

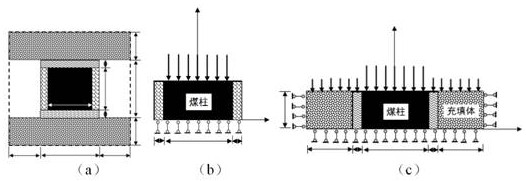

[0057] In this embodiment, the goaf that needs to be filled and treated is a room-and-pillar goaf in northern Shaanxi. The specific parameters of the goaf include: mining depth H is 200m, the bulk density of overlying rock gamma 24kN / m 3 , the width of the remaining coal pillar a 8m, the length of the remaining coal pillar l 8m, the remaining coal pillar height h 3m, the remaining coal pillar spacing b is 8m, the uniaxial compressive strength of coal σ s is 15MPa, the internal friction angle of coal φ s is 30°, the coefficient of broken expansion of coal k is 1.2, the angle of repose of the stacked body φ r is 40°, the elastic modulus of coal E s It is 1.5GPa.

[0058] According to the above technical solution, the present invention provides a method for designing key parameters of room-and-pillar goaf control filling, the method comprising:

[0059] Step 1. Carry out coal and rock mass sampling on the coal pillar left in the room-and-pillar type goaf, and test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com