Inclined milling surface appearance generating method based on machining physical process

A surface morphology and physical process technology, applied in the field of mechanical processing, can solve problems such as side milling without considering the surface morphology, and achieve the effect of optimizing process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

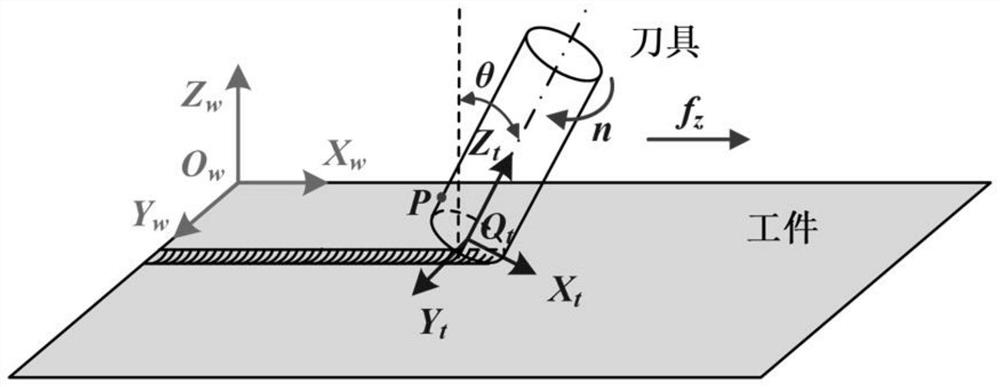

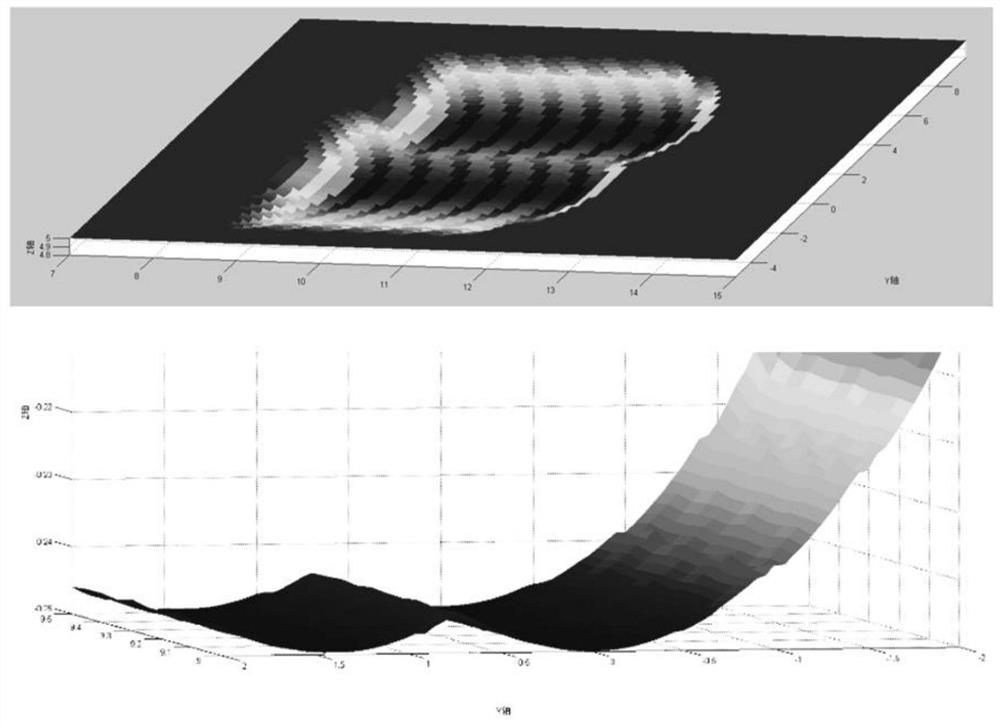

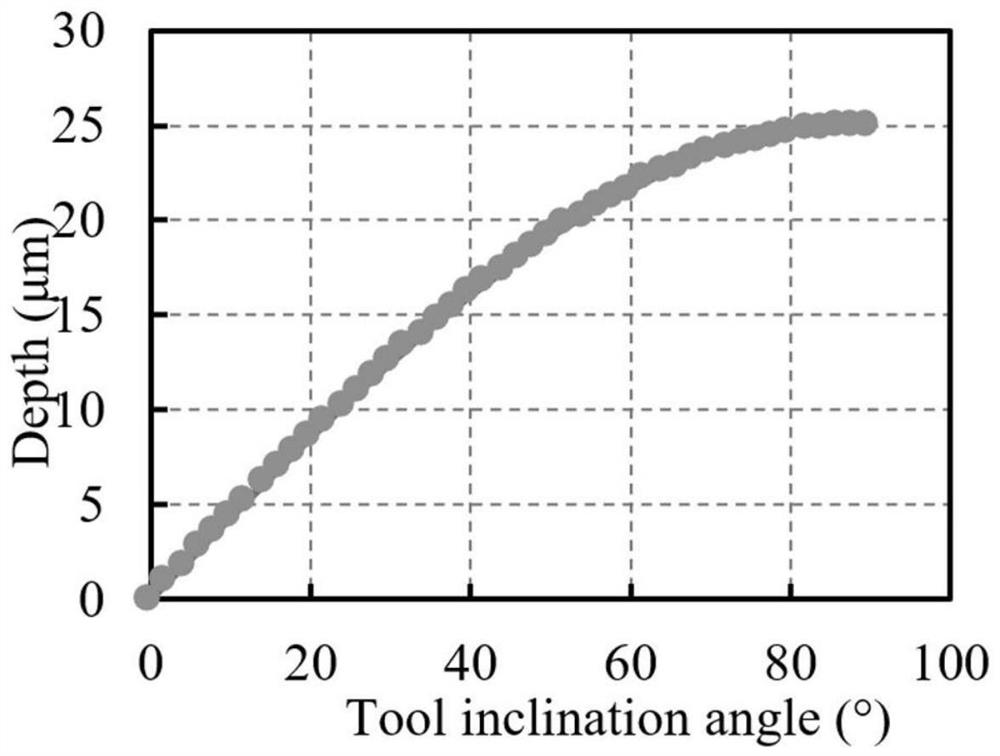

[0019] This embodiment relates to a system for creating and analyzing macro and micro-ordered textures on milling surfaces, including: an inclined milling tool trajectory generation unit, a surface topography simulation unit, a surface roughness parameter calculation unit, and an inclined milling process parameter optimization unit, wherein : The inclined milling tool trajectory generation unit generates a series of discrete tool trajectory according to the input milling process parameters and tool geometric parameter information; the surface topography simulation unit performs Boolean operations according to the discrete tool trajectory to obtain the inclined milling surface shape appearance; the surface roughness parameter calculation unit calculates the required roughness parameters, such as Sa, Ra, etc., according to the surface topography obtained by simulation; the inclined milling process parameter optimization unit calculates the corresponding relationship, optimize the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com