Quick charging device and method for forklift

A fast charging and forklift technology, applied in the field of forklifts, can solve the problems of affecting the service life, high price, long charging time, etc., to ensure the discharge capacity, reduce the procurement cost, and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

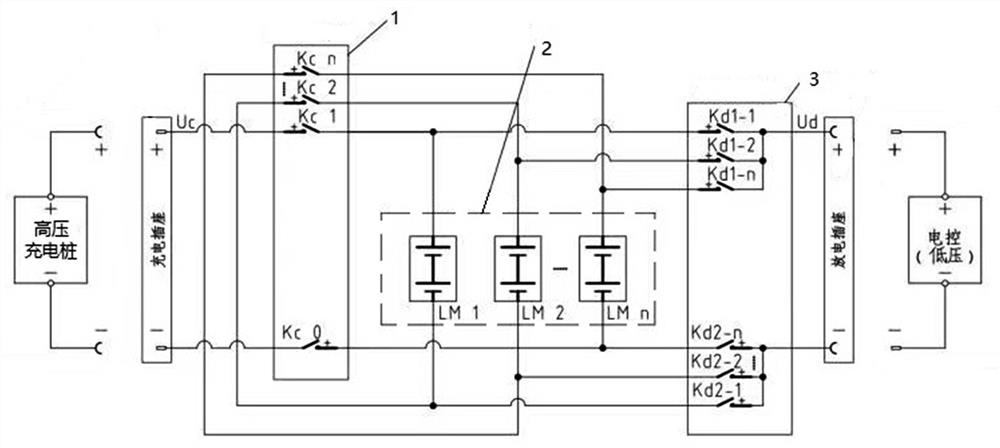

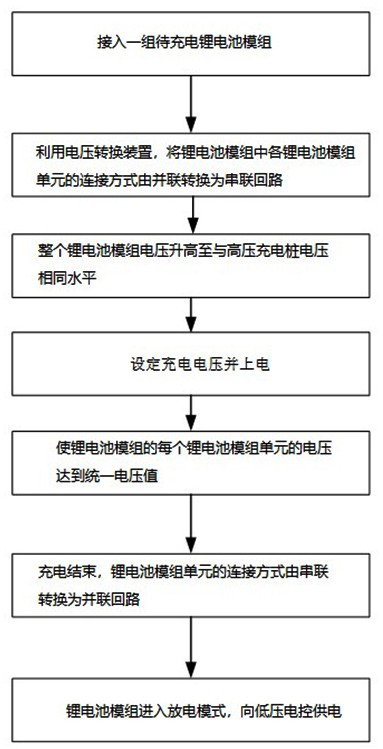

[0049] A lithium battery module 2, including four 96V / 150Ah identical lithium battery module 2 units L M1 / L M2 / L M3 / L M4 , each lithium battery module 2 unit is composed of six 16V / 150Ah lithium battery cells connected in series. 600Ah, the battery pack contains a BMS power management system, which consists of 5 charging contactors K c0、 K c1、 K c2、 K c3、 K c4 The charging contactor group 1 composed of 6 discharging contactors K d1-1、 K d1-2、 K d1-3、 K d2-1、 K d2-2、 K d2-3 Composed of discharge contactor group 3. When the high-voltage charging pile is powered on, K c0、 K c1、 K c2、 K c3 The contact is closed and the current flows through the positive pole of the charging socket -> K c1 -> L M-1 -> K c2 -> L M-2 -> K c3 -> L M-3 -> K c4 -> L M-4 -> K c0 -> The negative pole of the charging socket connects 4 lithium battery modules 2 units in series. At this time, the output voltage of the high-voltage charging pile is 96V*4=384V, and the standard ou...

Embodiment 2

[0051] A lithium battery module 2, including two 76.8V / 272Ah lithium battery module 2 units L with identical specifications M1 / L M2 , each module unit is composed of three 25.6V / 272Ah lithium battery cells connected in series, the voltage of the whole battery pack is 25.6V*3=76.8V, and the capacity is 272Ah*2=514Ah, so the specification of the whole battery pack is 76.8V / 514Ah, the battery pack contains a BMS power management system, which consists of 3 charging contactors K c0、 K c1、 K c2 The charging contactor group 1 composed of 4 discharging contactors K d1-1、 K d1-2、 K d2-1、 K d2-2 Composed of discharge contactor group 3. When the high-voltage charging pile is powered on, K c0、 K c1、 K c2 The contact is closed and the current flows through the positive pole of the charging socket -> K c1 -> L M-1 -> K c2 -> L M-2 -> K c0 -> The negative pole of the charging socket connects two lithium battery modules in series. At this time, the output voltage of the high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com