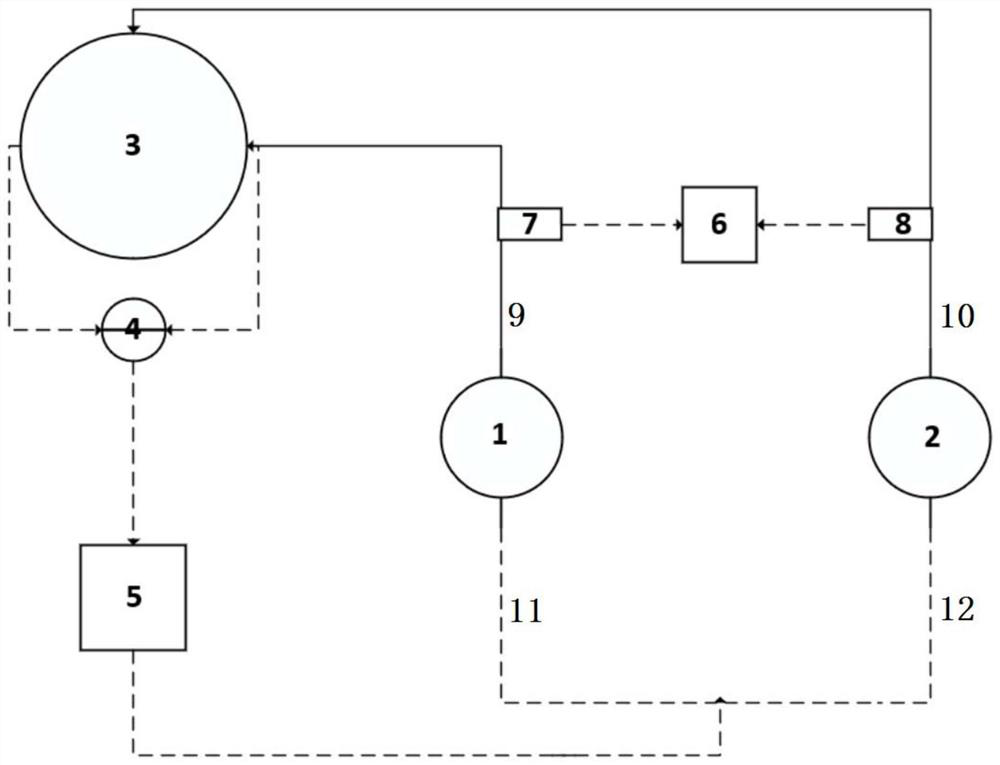

System and method for combined control of backwashing water pump and drum-shaped filter screen

A technology of joint control and control system, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the hidden dangers of backflushing water pipes, lack of interlocking, and failure of backwashing water pipes, etc. The effect of optimizing the startup time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The specific work process of this embodiment is:

[0038] 1) The cooling water filtration system is in normal operation, and entering the drum-shaped filter 3 is seawater that has been preliminarily filtered and added with medicine. , attached to the drum-shaped filter screen 3, when the drum-shaped filter screen 3 has less dirt attached, and the differential pressure gauge 4 before and after the drum screen shows no abnormality, the first backwash water pump 1 and the second backwash water pump 2 are both When not running, the cooling water passes through the drum filter 3 to provide qualified water for downstream users, and the cooling water filtering system operates normally.

[0039] 2) When some foreign matter exists in the preliminary filtered seawater entering the drum filter 3 and blocks the filter surface of the drum filter 3, the water pressure difference between the front and back of the drum filter 3 will be greater than or equal to 0.1mH 2 O, start the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com