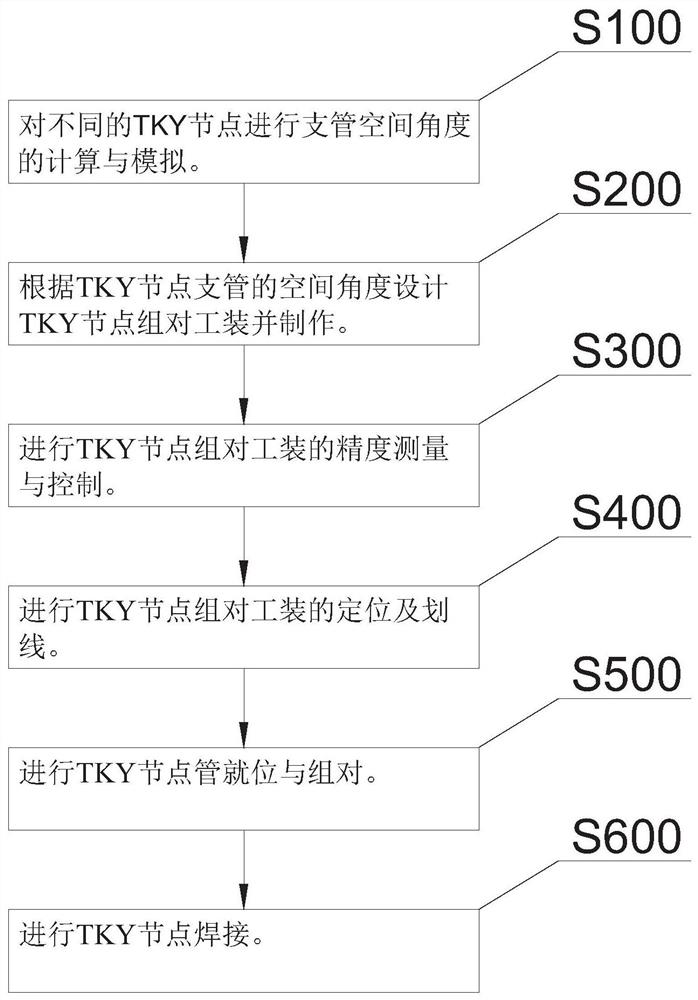

Batch welding method for steel structure TKY joints

A welding method and steel structure technology, applied in the direction of welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of non-repetitive single projects, achieve batch production, reduce construction costs, and improve construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

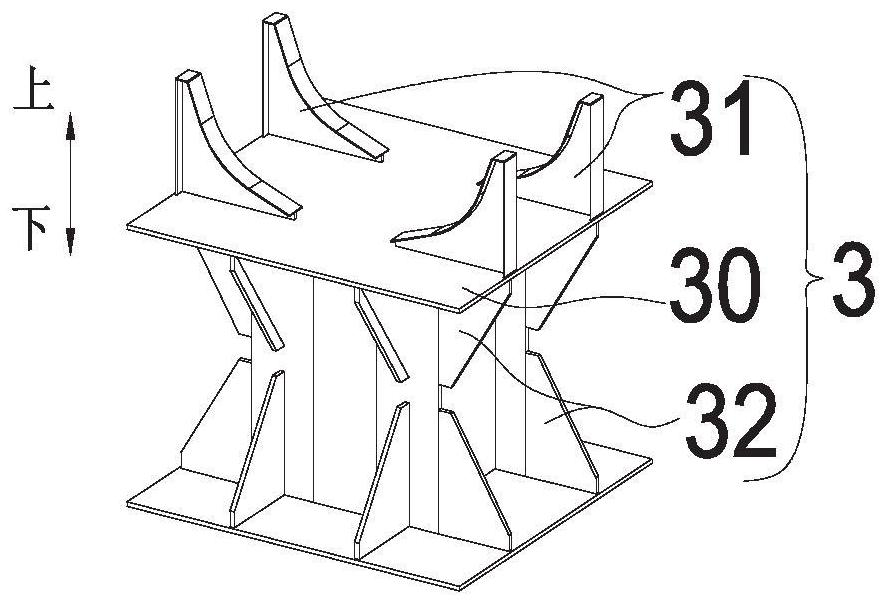

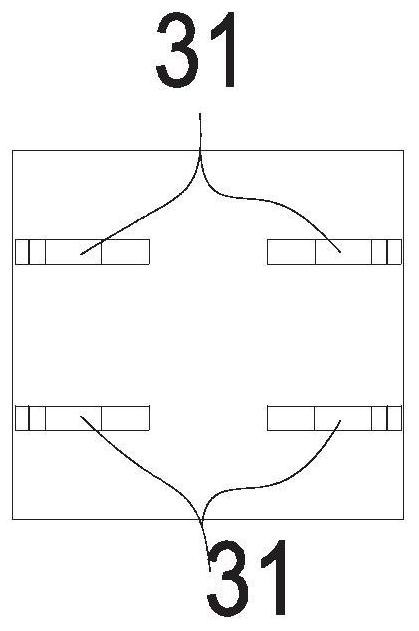

[0073] Using the batch welding method of the above steel structure TKY joints, such as Figure 6 and Figure 7 As shown, it is used for the positioning and support of the main pipe 1 and its welded branch pipe 2 at its node. The TKY node assembly tooling includes two steel pier 3 and branch pipe support pier 4. The two steel pier 3 are used for the positioning of the main pipe 1. and the supporting main pipe 1 are placed horizontally; if figure 2 and image 3 As shown, the steel pier 3 includes an "I"-shaped base seat 30 and two pairs of symmetrically distributed on both sides of the top of the "I"-shaped base seat 30, which are used to support the main pipe 1 according to the diameter of the main pipe 1. Support and position the fixed arc-shaped baffle 31, the arc-shaped surface of the arc-shaped baffle 31 is set close to the outer wall of the main pipe 1, and the upper and lower sides of the "I"-shaped base frame seat 30 are welded to the top surface and the bottom respec...

Embodiment 2

[0084] Such as Figure 10 and Figure 11 As shown, the difference from Embodiment 1 is that in the TKY node assembly tooling, four branch pipe support piers 4 are used to respectively fix and support the four branch pipes 2 at the node of the main pipe 1, and the branch pipe support piers 4 include supporting and fixing The support seat 40 placed obliquely on the branch pipe 2 and the thrust stopper 41 positioned against the outer end of the branch pipe 2 along the opposite direction of the branch pipe 2 axial direction relative to the other end of the branch pipe 2 node, the support seat 40 and the thrust stopper 41 is fixed on the same bottom plate 42; the supporting seat frame 40 is set close to the node side of the branch pipe 2, and the thrust block 41 is located outside the supporting seat frame 40 along the axial direction of the branch pipe 2; the supporting seat frame 40 is formed to cooperate with the outer wall of the branch pipe 2 The arc-shaped support groove 400...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com