Multifunctional spun-melt non-woven fabric and preparation method thereof

A non-woven, multi-functional technology, applied in chemical instruments and methods, protective equipment, other household appliances, etc., can solve the problems of textiles that do not provide both flexible and rigid dual performance, and improve impact resistance and puncture resistance. , Improve the scope of application and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

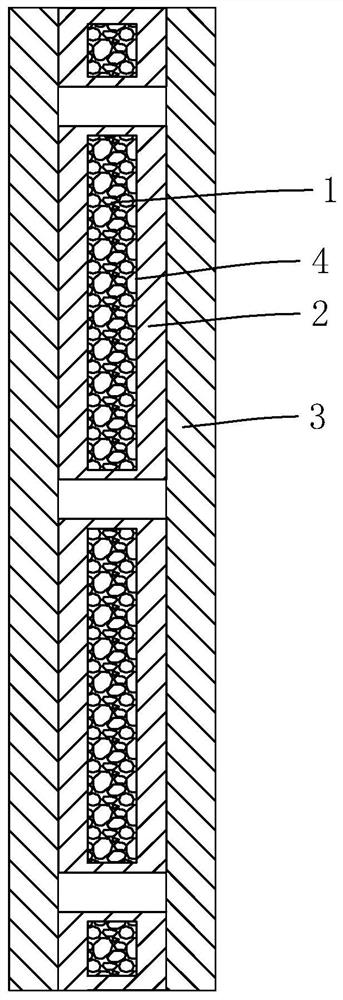

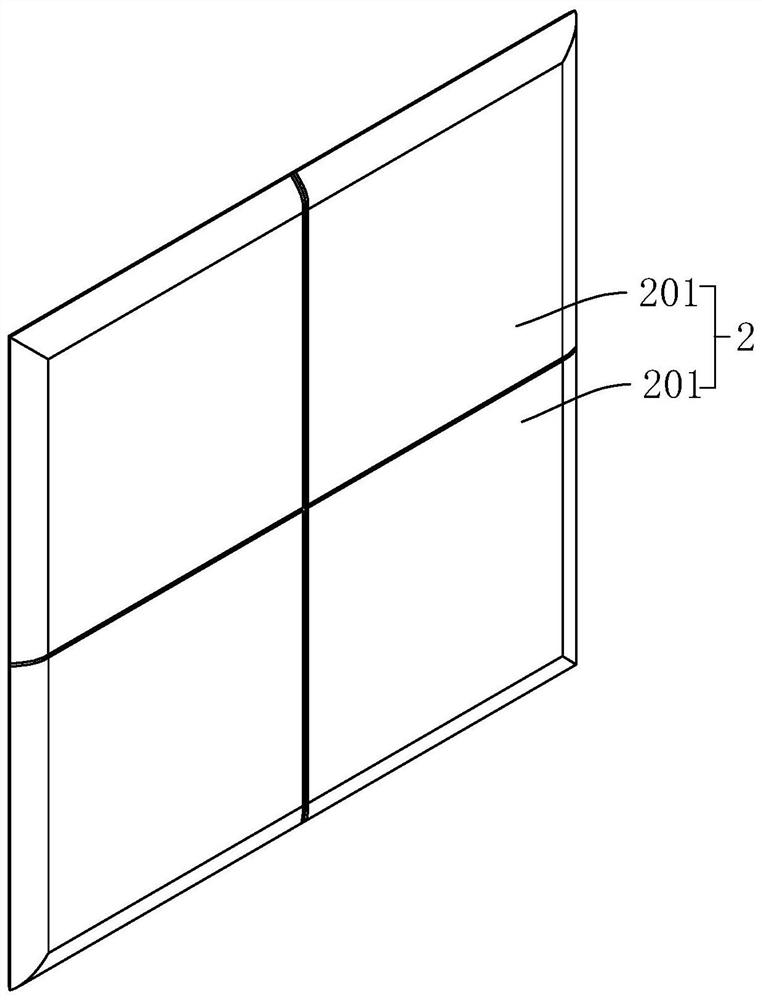

[0046] Embodiment 1: a kind of multifunctional spunmelt nonwoven fabric, with reference to figure 1 , which includes an expansion plastic fluid 1 , a PVC cloth 2 for containing the expansion plastic fluid 1 , and a fiber net layer 3 arranged sequentially from the inside to the outside.

[0047] Wherein, the PVC cloth 2 has a double-layer structure and the two layers are respectively located on both sides of the expansion fluid 1, so a chamber 4 is formed in the PVC cloth 2, and the edge of the PVC cloth 2 is sealed by heat sealing. The PVC fabric 2 is provided with a through hole for the needle loom to penetrate. In this embodiment, the diameter of the through hole is 2mm, and the through hole is not connected to the inside of the PVC fabric 2 .

[0048] Multifunctional spunmelt nonwovens are prepared through the following steps:

[0049] Step 1, preparing dilatant fluid:

[0050] Mix starch and water evenly at a ratio of 2:1 to obtain swellable fluid 1; inject swellable flu...

Embodiment 2

[0056] Example 2: A multifunctional spunmelt nonwoven fabric, the difference from Example 1 is that in step 1, starch and water are evenly mixed in a ratio of 2.5:1 to obtain a swelling plastic fluid.

Embodiment 3

[0057] Example 3: A multifunctional spunmelt nonwoven fabric, the difference from Example 1 is that in step 1, starch and water are evenly mixed in a ratio of 3:1 to obtain a swelling plastic fluid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com