Gas ultrasonic transducer impedance gradient matching layer and preparation method thereof

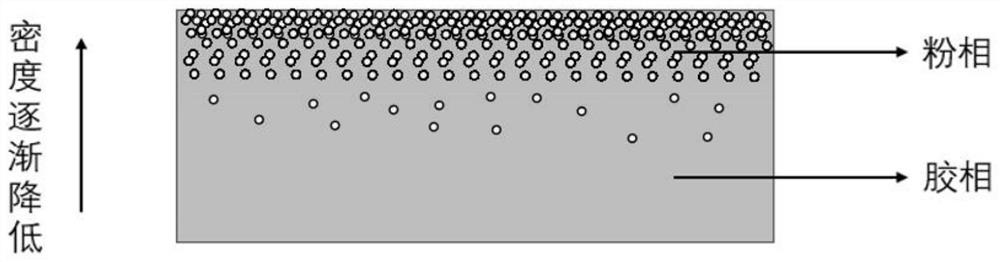

A technology of impedance gradient and matching layer, which is applied in the field of gas ultrasonic transducer impedance gradient matching layer and its preparation, can solve the problems of high material cost, low acoustic impedance, processing difficulty and high processing cost, etc., and achieve simple process method, Raw materials are easy to obtain and the effect of continuous impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1, a gas ultrasonic transducer impedance gradient matching layer, its raw materials include a matrix material composed of epoxy resin E-51, 593 epoxy resin curing agent, and a reinforcing material of modified hollow quartz powder;

[0017] The mass ratio of epoxy resin E-51 and 593 epoxy resin curing agent in the matrix material is 3:1;

[0018] The reinforcing material hollow quartz powder is 5% of the mass of the base material.

[0019] A method for preparing an impedance gradient matching layer of a gas ultrasonic transducer, comprising the following steps:

[0020] Step 1, preparation of base material: Weigh epoxy resin E-51 and 593 epoxy resin curing agent respectively according to the mass ratio of 3:1, first add epoxy resin E-51 to the beaker, then add 593 epoxy resin to cure agent, stirred evenly, and ultrasonically dispersed for 120s in an ultrasonic cleaning machine using a degassing procedure to obtain a matrix material;

[0021] Step 2, preparat...

Embodiment 2

[0023] Embodiment 2, a gas ultrasonic transducer impedance gradient matching layer, its raw materials include a matrix material composed of epoxy resin E-51 and 593 epoxy resin curing agent, and a reinforcing material of modified hollow quartz powder;

[0024] The mass ratio of epoxy resin E-51 and 593 epoxy resin curing agent in the matrix material is 6:1;

[0025] The reinforcing material hollow quartz powder is 10% of the mass of the matrix material.

[0026] A method for preparing an impedance gradient matching layer of a gas ultrasonic transducer, comprising the following steps:

[0027] Step 1, preparation of matrix material: Weigh epoxy resin E-51 and 593 epoxy resin curing agent respectively according to the mass ratio of 6:1, first add epoxy resin E-51 to the beaker, then add 593 epoxy resin to cure agent, stirred evenly, and ultrasonically dispersed for 300s in an ultrasonic cleaning machine using a degassing procedure to obtain a matrix material;

[0028] Step 2, ...

Embodiment 3

[0030] Embodiment 3, a gas ultrasonic transducer impedance gradient matching layer, its raw materials include a matrix material composed of epoxy resin E-51, 593 epoxy resin curing agent, and a reinforcing material of modified hollow quartz powder;

[0031] The mass ratio of epoxy resin E-51 and 593 epoxy resin curing agent in the matrix material is 5:1;

[0032] The reinforcing material hollow quartz powder is 30% of the mass of the base material.

[0033] A method for preparing an impedance gradient matching layer of a gas ultrasonic transducer, comprising the following steps:

[0034] Step 1, preparation of matrix material: Weigh epoxy resin E-51 and 593 epoxy resin curing agent respectively according to the mass ratio of 5:1, first add epoxy resin E-51 to the beaker, then add 593 epoxy resin to cure agent, stirred evenly, and ultrasonically dispersed for 300s in an ultrasonic cleaning machine using a degassing procedure to obtain a matrix material;

[0035] Step 2, prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com